Semiconductor laser module, method for stabilizing and denoising semiconductor laser, and solid laser

A laser module and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as noise, mode hopping phenomenon, mode allocation, etc., and achieve the effect of improving randomness, eliminating mode hopping, and eliminating mode allocation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described below with reference to the drawings.

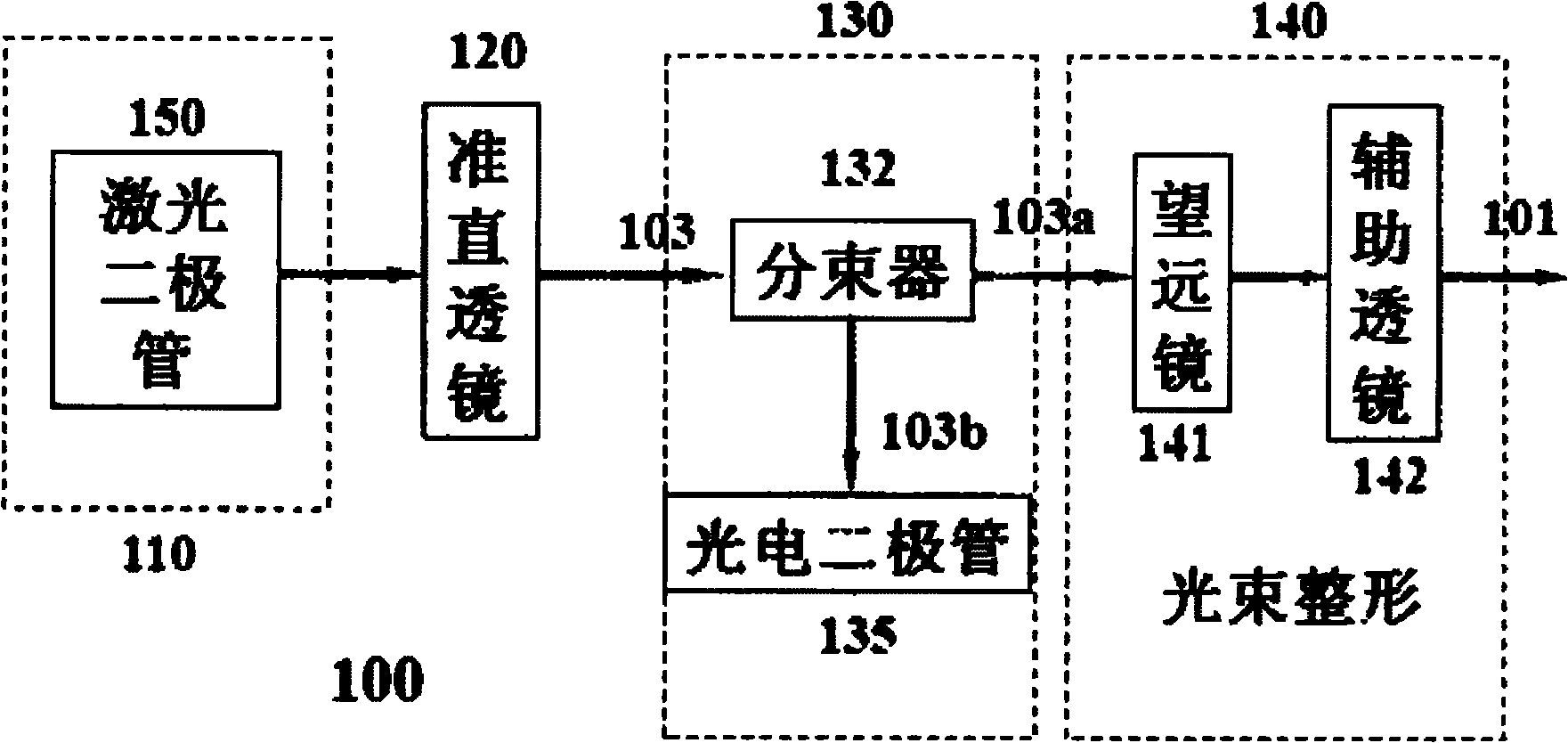

[0046] Such as figure 1 As shown, the basic optical structure of the semiconductor laser module 100 includes a laser assembly 110 with a semiconductor laser tube 150 (also called a semiconductor laser) as the core, a collimator lens 120, a feedback signal sampling assembly 130, and a telescope 141 and an auxiliary lens 142. beam shaping assembly 140 . The feedback signal sampling component 130 also includes a beam splitter 132, whose function is to divide the collimated laser output 103 into two parts, most of the light 103a is output after beam shaping, and a small part of the separated light 103b enters the photodiode 135 generates a feedback signal.

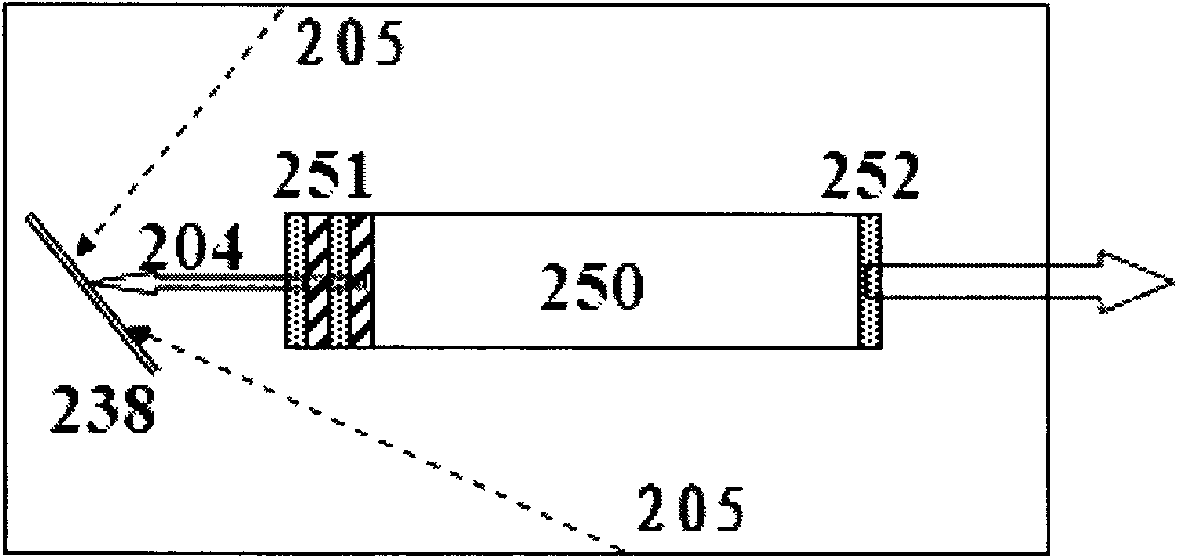

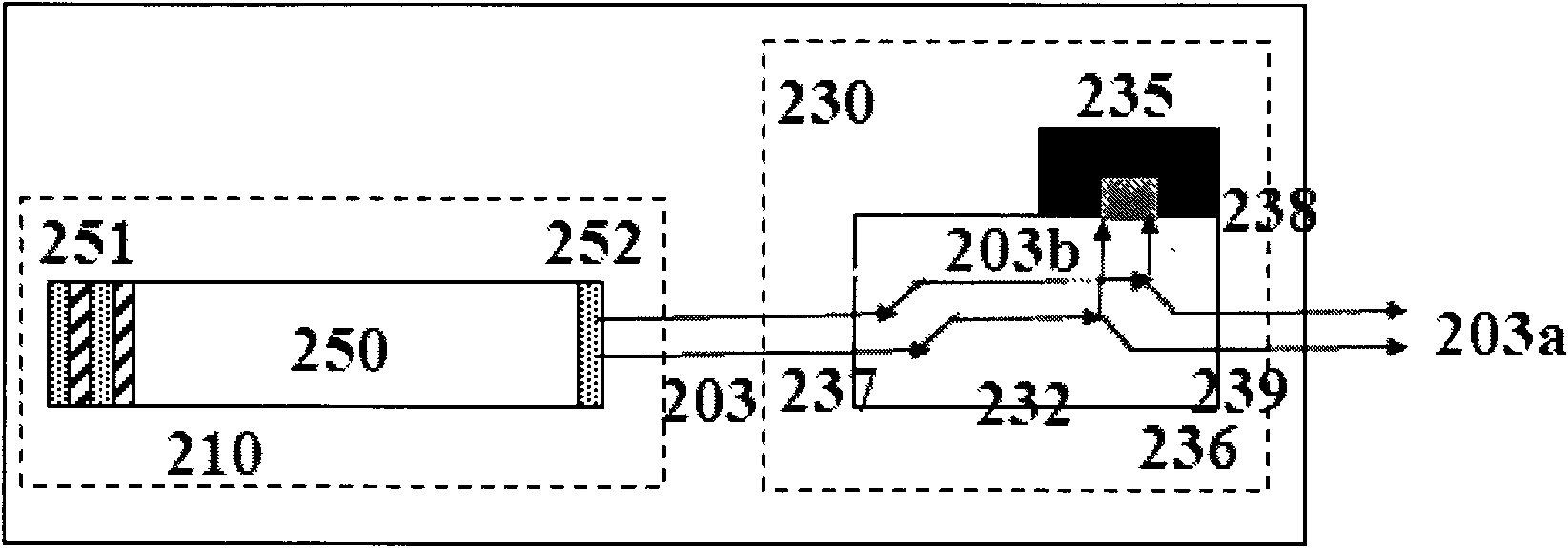

[0047] Figure 2b A sampling system for an improved automatic power control system is described. The beam splitter 232 is enclosed in a box 236 . The closed box has only one entrance 237 to receive the light bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com