Pretreatment method of burley tobacco shred and application thereof in cigarette product

A technology of burley shredded tobacco and cigarettes, which is applied to cigarette products. The field of pretreatment of burley shredded tobacco can solve the problems of reducing the harm and tar of cigarettes, the negative impact of cigarette smoking and eating, and the high tar content of cigarettes. Achieve the effects of improving compatibility, improving coordination, reducing miscellaneous gas and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

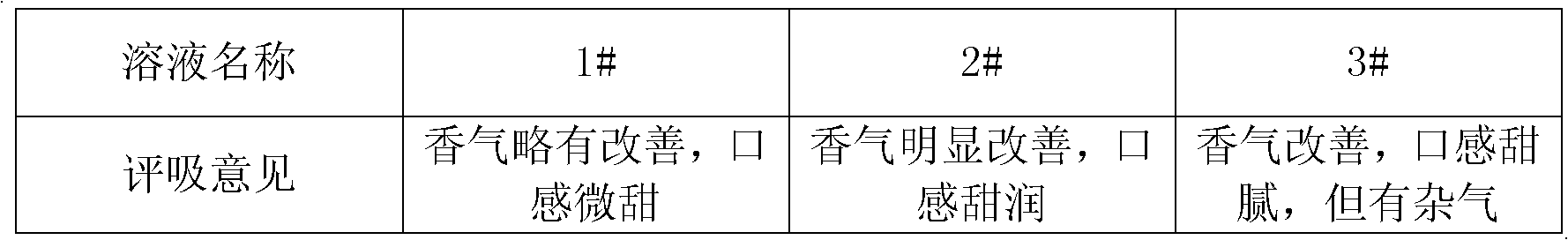

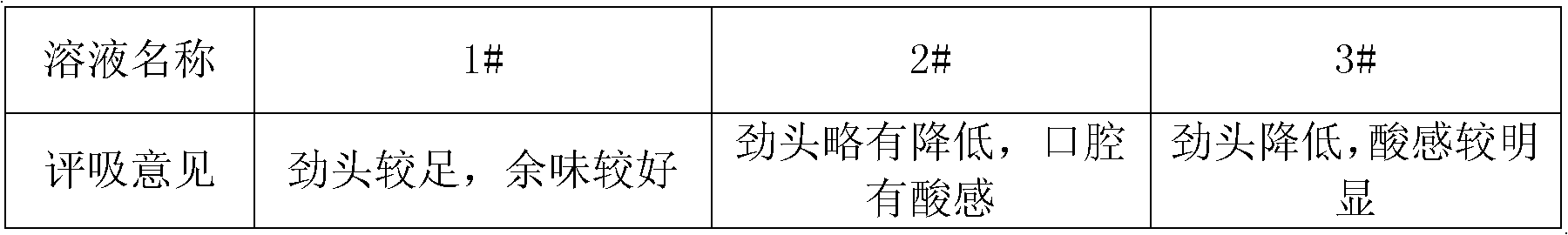

Embodiment 1

[0038] The present invention comprises the following steps:

[0039] (1), prepare the solution according to the weight ratio of water: honey: lactic acid=500:5:1 for subsequent use;

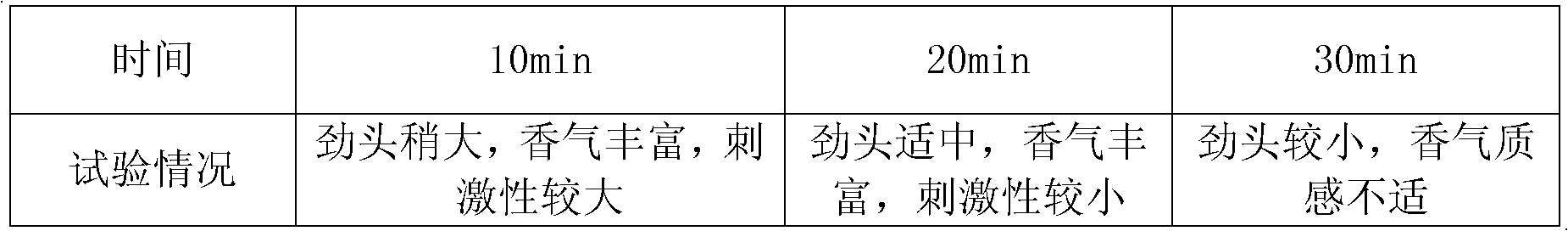

[0040] (2), take Burley shredded tobacco, join in the above-mentioned preparation solution according to the weight ratio of Burley shredded tobacco and the preparation solution being 1:5, then heat to boiling, and the boiling time is 20 minutes;

[0041] (3), then cool, filter out the aqueous solution, place in an oven and dry until the moisture content is 12%, and the oven temperature is set at 50°C-60°C. Wherein said honey is the natural honey with water content lower than 20%.

[0042] The application of shredded Burley tobacco of the present invention in cigarette products includes:

[0043] (1), prepare the solution according to the weight ratio of water: honey: lactic acid=500:5:1 for subsequent use;

[0044] (2), take Burley shredded tobacco, join in the above-mentioned preparation solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com