Method for fast synthesizing mesoporous solid acid catalyst immobilized with sulfonic acid

A solid acid catalyst and sulfonic acid-carrying technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve obstacles to popularization and application, high production costs, Complicated process and other issues, to achieve good reactivity, large immobilization capacity, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

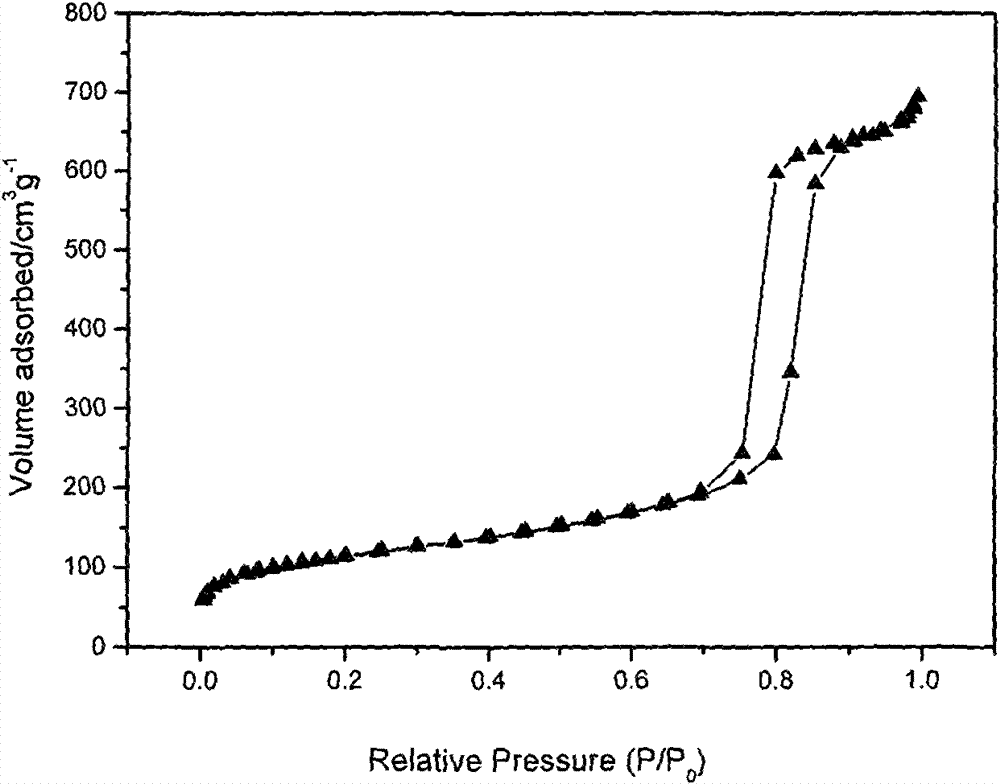

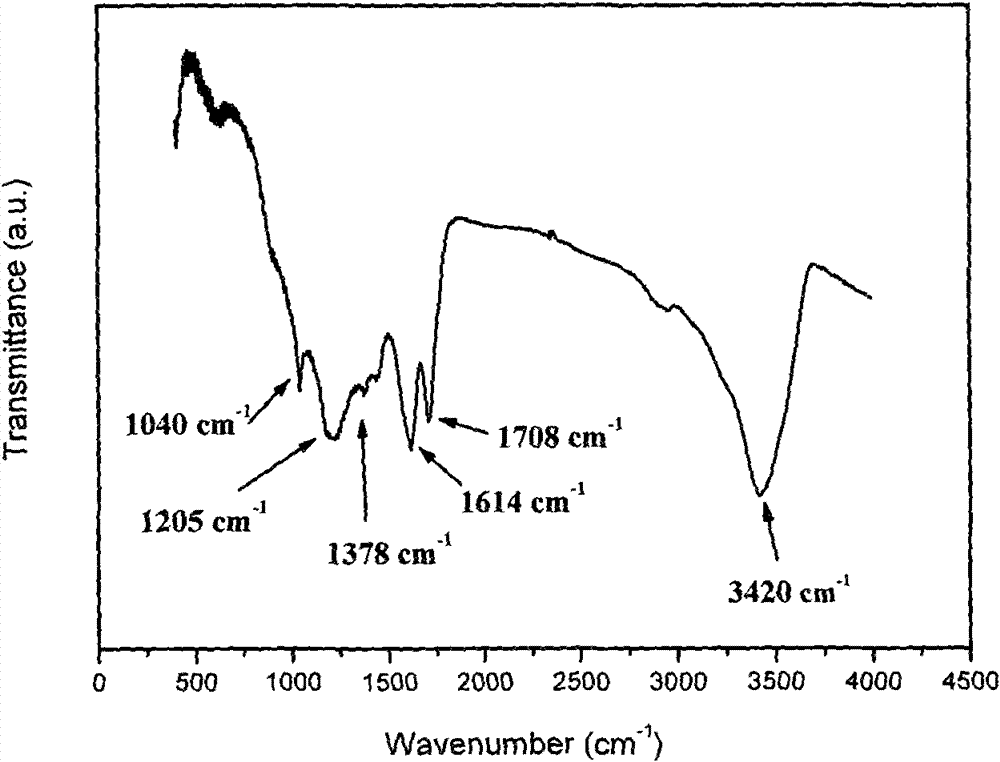

[0017] Add 1.0 g of SBA-15 mesoporous molecular sieve without template removal to 100 ml of sulfuric acid solution with a sulfuric acid mass fraction of 80%, heat the sulfuric acid solution to 190 ° C, stir for 3 h, cool to room temperature, suction filter, and wash until the filtrate is Neutral, the obtained solid is dried at 100°C; each gram of solid is extracted with 200ml ethanol for 24 hours, and dried at 100°C for 24 hours to obtain a mesoporous solid acid catalyst immobilized with sulfonic acid.

[0018] Catalytic effect: Add 0.20g of catalyst, 20ml of n-hexane as solvent, 100mmol of n-heptanal, 110mmol of ethylene glycol in a three-necked flask, reflux for 120min, the conversion rate of n-heptanal is 92%, and the selectivity of product acetal is 98%.

Embodiment 2

[0020] Add 5.0 g of SBA-15 mesoporous molecular sieves without template removal to 200 ml of sulfuric acid solution with a sulfuric acid mass fraction of 80%, heat the sulfuric acid solution to 190 ° C, stir for 3 h, cool to room temperature, suction filter, and wash until the filtrate is Neutral, the obtained solid is dried at 100°C; each gram of solid is extracted with 200ml of ethanol for 48 hours, and dried at 100°C for 36 hours to obtain a mesoporous solid acid catalyst immobilized with sulfonic acid.

[0021] Catalytic effect: Add 0.20g of catalyst, 20ml of n-hexane as solvent, 50mmol of n-heptanal, 55mmol of ethylene glycol in a three-necked flask, and reflux for 120min. The conversion rate of n-heptanal is 86%, and the selectivity of product acetal is 98%.

Embodiment 3

[0023] Add 10.0 g of SBA-15 mesoporous molecular sieves without template removal to 500 ml of sulfuric acid solution with a sulfuric acid mass fraction of 90%, heat the sulfuric acid solution to 195°C, stir for 4 hours, cool to room temperature, suction filter, and wash until the filtrate is Neutral, the obtained solid is dried at 100°C; each gram of solid is extracted with 200ml of ethanol for 48 hours, and dried at 100°C for 24 hours to obtain a mesoporous solid acid catalyst immobilized with sulfonic acid.

[0024] Catalytic effect: add catalyst 0.20g, 20ml n-hexane as solvent, 50mmol n-heptanal, 55mmol ethylene glycol in a three-necked flask, reflux for 120min, the conversion rate of n-heptanal is 82%, and the selectivity of product acetal is 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com