Equipment and method for treating oil extraction wastewater with integration of coalescence and hydrocyclone separation

A technology for oil extraction wastewater and cyclone separation, which is applied in centrifugal separation of water/sewage treatment, separation methods, liquid separation, etc. , the effect of reducing cost input and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

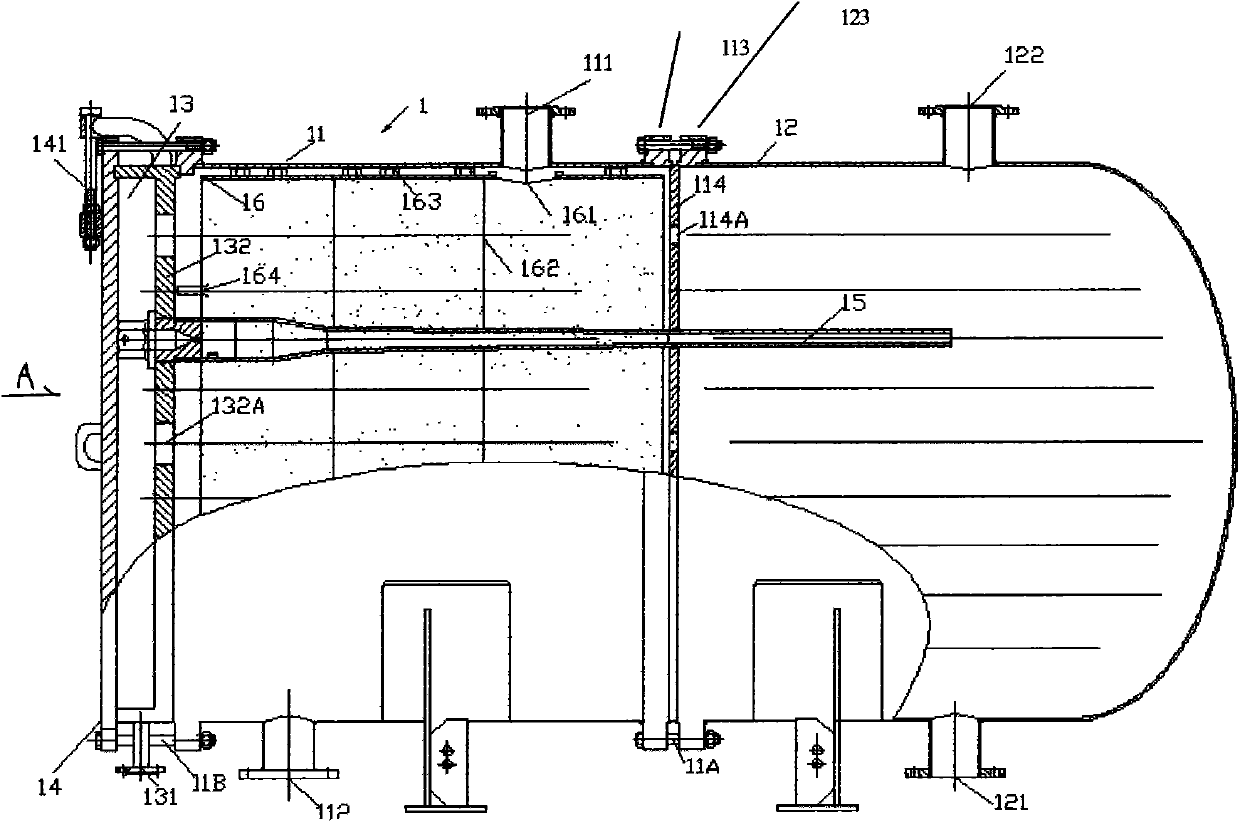

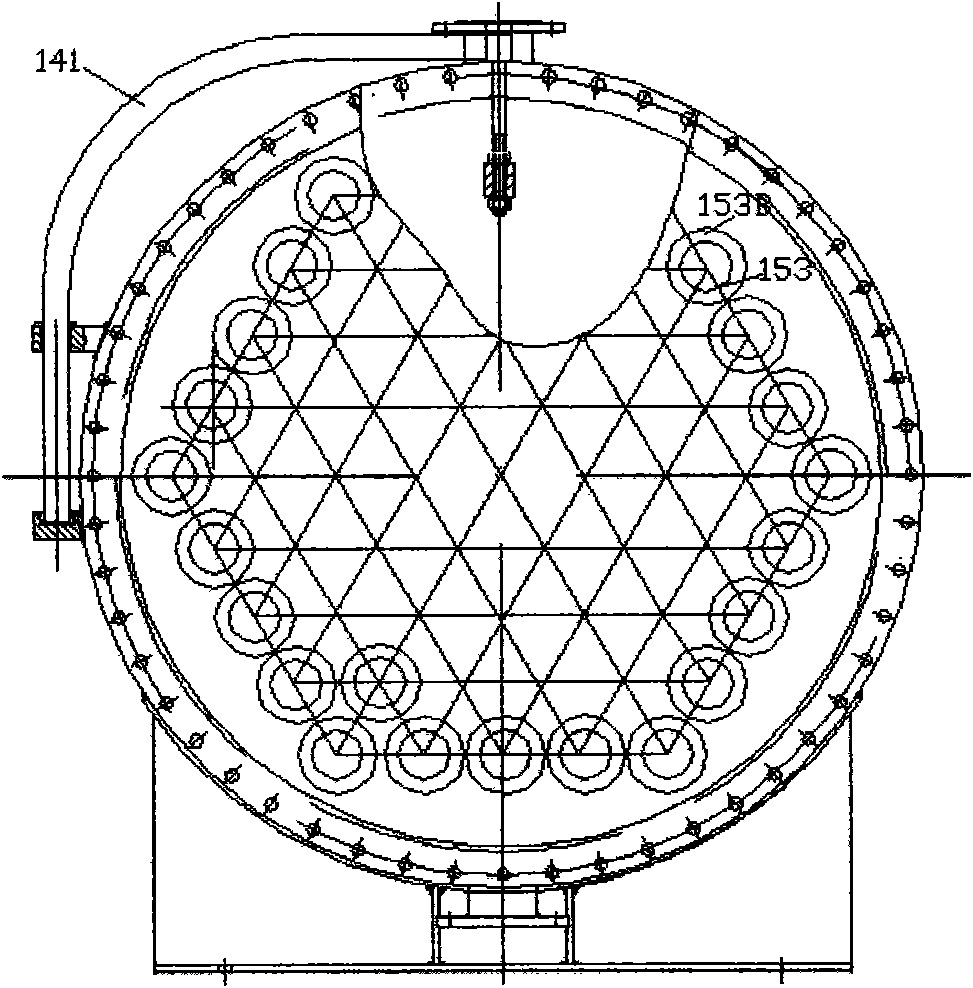

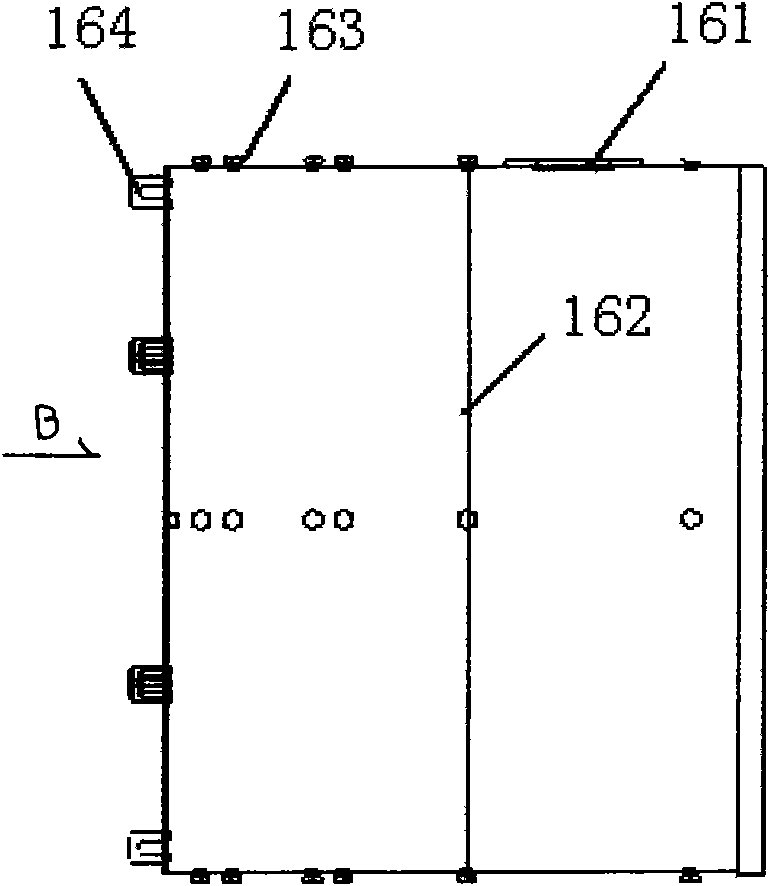

[0026] The present invention can be implemented according to the accompanying drawings, which will be described in further detail below in conjunction with the accompanying drawings:

[0027] Depend on figure 1 It is shown that the coalescing and cyclone separation integrated oil production wastewater treatment equipment is mainly composed of an inlet chamber 11, an underflow chamber 12, an overflow chamber 13 and a flat head 14, wherein: the cylinder body of the inlet chamber 11 is equipped with One flange is the oil production waste water inlet 111 and the backup port 112 respectively. The inlet port 11 is also equipped with a box flange 113; Port 122, the underflow cavity 12 is also equipped with a box flange 123; the inlet cavity 11 and the underflow cavity 12 are connected and fixed through the box flanges 113, 123 and bolts 11A, and the inlet cavity 11 and the underflow cavity 12 are connected by bolts 11A The right partition 114 is clamped and fixed, and the tail of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com