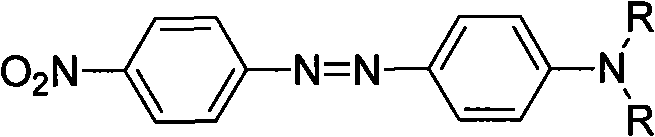

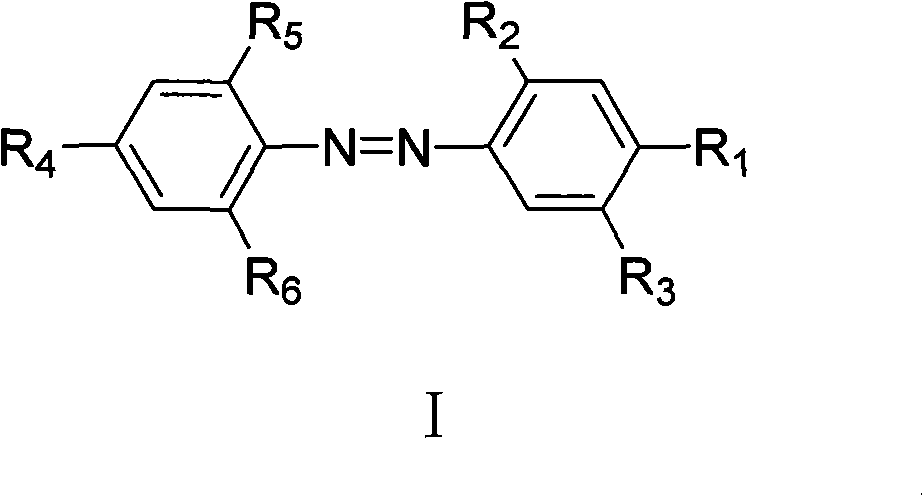

Azo allergenic disperse dye, and purifying method and application thereof

A purification method and technology for disperse dyes, applied in the field of azo sensitizing disperse dyes, can solve the problems of low purity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take Waters Xterra C 18 (5μm, 19×100mm) chromatographic column; the mobile phase is methanol: water (40:60) and linearly changes to methanol: water (95:5) in 7 minutes; the detection wavelength is 450nm; the flow rate is 15ml / min.

[0027] Dissolve 5g of Disperse Orange 1 commercial dye with 50ml of methanol: water (40:60), filter, inject 5ml each time, collect the effluent of 4.2min-4.9min, evaporate the collected solution to dryness, and obtain 100mg of solid. After analysis, the purity was 99.2%.

Embodiment 2

[0029] Take Waters Xterra C 18 (5μm, 19×100mm) chromatographic column; the mobile phase is methanol: water (40:60) and linearly changes to methanol: water (95:5) in 7 minutes; the detection wavelength is 450nm; the flow rate is 18ml / min.

[0030] Dissolve 5g of Disperse Orange 3 commercial dye with 50ml of methanol: water (40:60), filter, inject 5ml each time, collect the effluent of 3.8min-4.5min, evaporate the collected solution to dryness, and obtain 95mg of solid. After analysis, the purity was 98.2%.

Embodiment 3

[0032] Take Waters Xterra C 18 (5μm, 19×100mm) chromatographic column; the mobile phase is methanol: water (20:80) and linearly changes to methanol: water (95:5) in 7 minutes; the detection wavelength is 450nm; the flow rate is 24ml / min.

[0033]Dissolve 5g of Disperse Orange 37 commercial dye with 50ml of methanol: water (20:80), filter, inject 5ml each time, collect the effluent of 3.7min-4.8min, evaporate the collected solution to dryness, and obtain 90mg of solid. After analysis, the purity 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com