Garbage disposal unit

A waste treatment device and reaction chamber technology, which is applied in special dry distillation, petroleum industry, coking oven, etc., can solve problems such as safety accidents, high temperature, and polluted environment, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

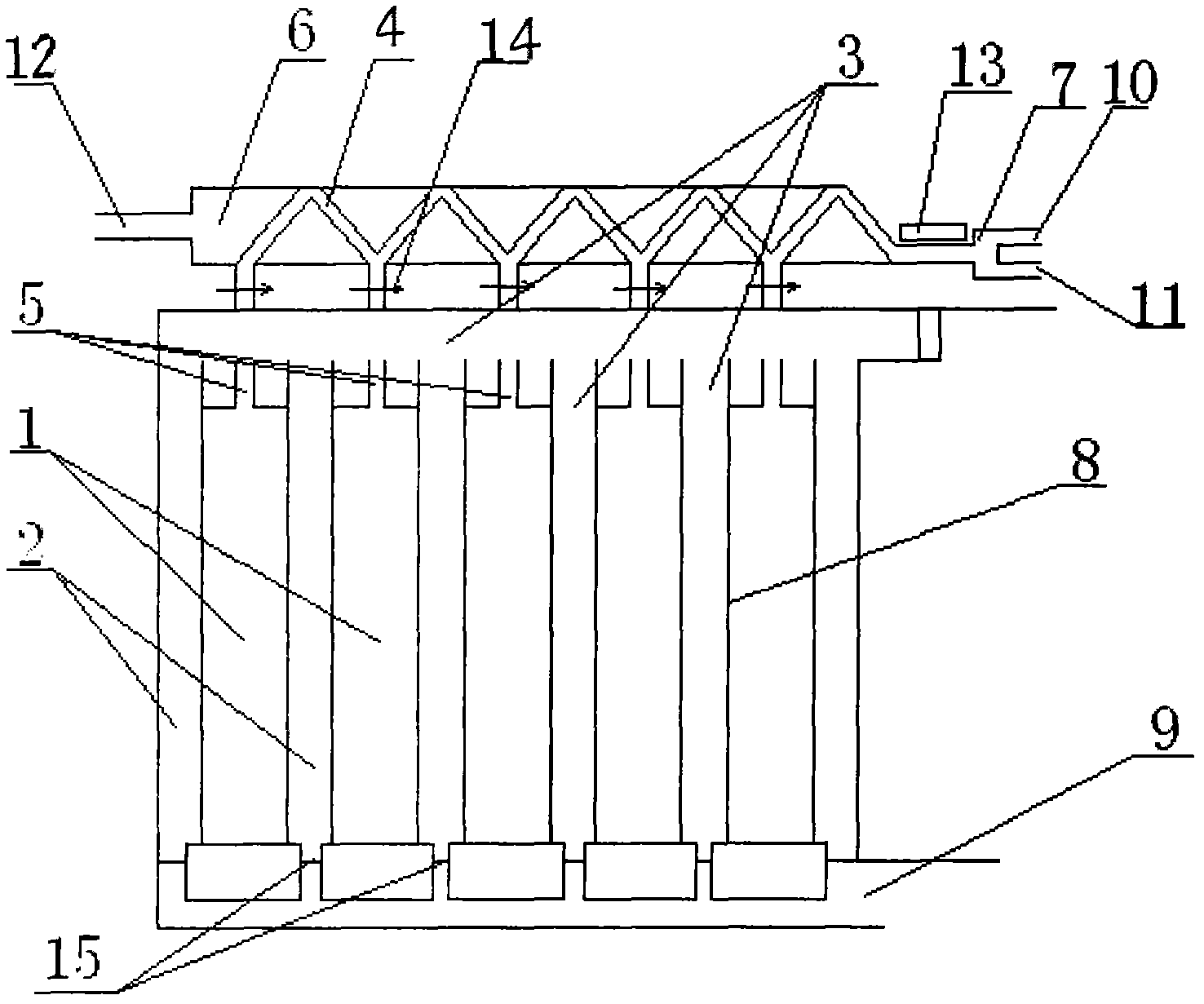

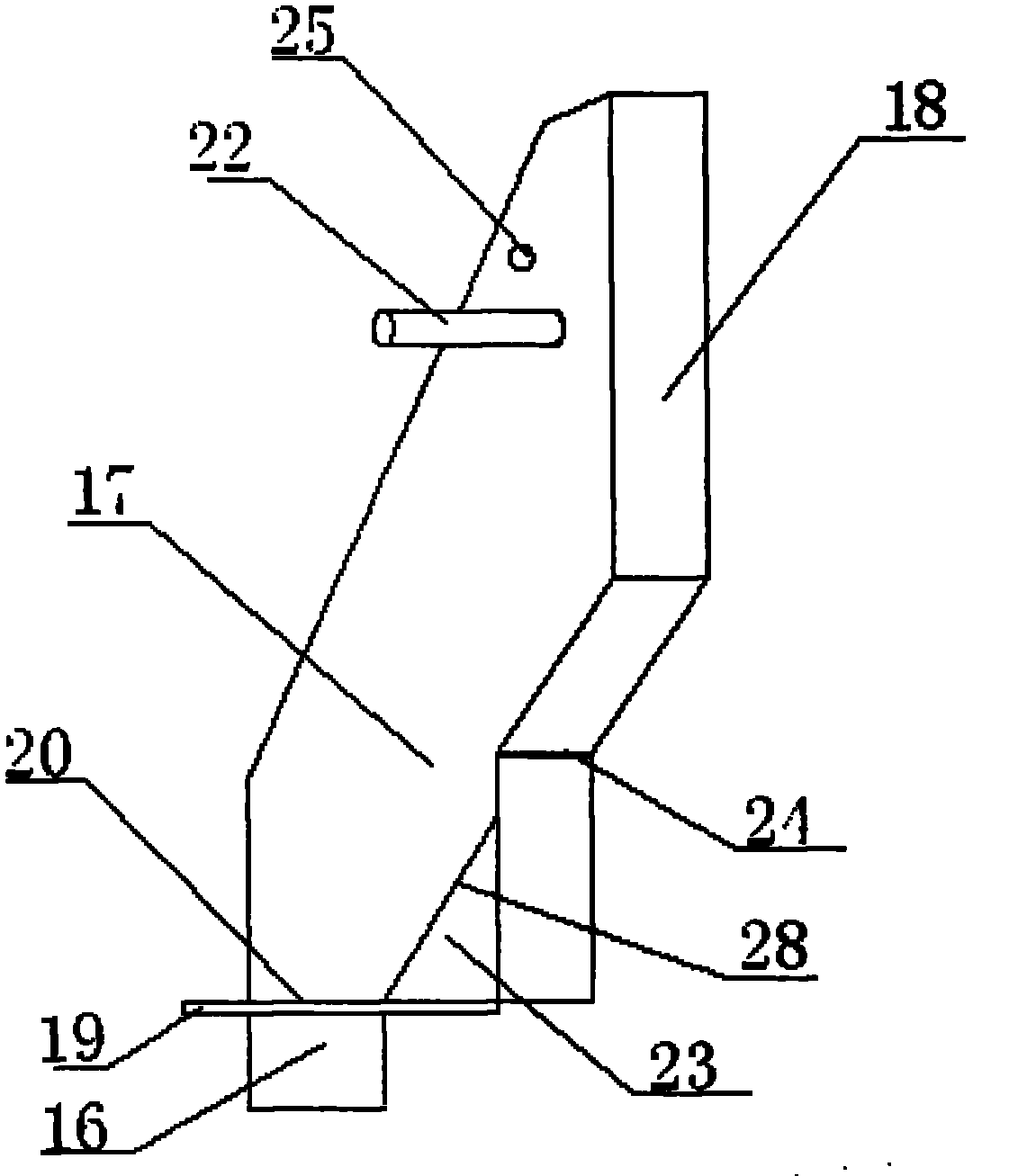

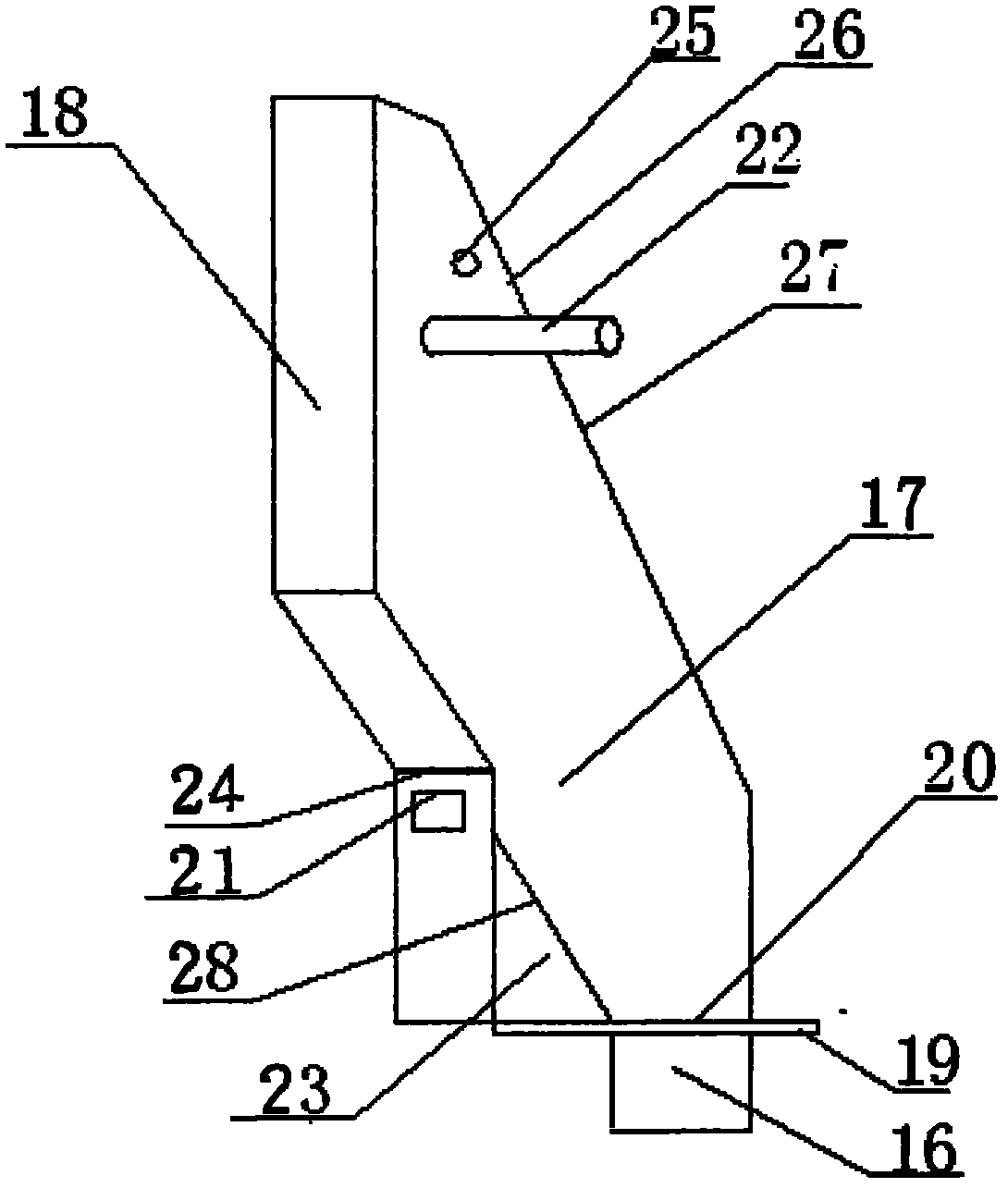

[0015] The garbage treatment device of the present invention is composed of a reaction chamber 1, a combustion chamber 2, a heat transfer pipe 3, a collection pipe 4, a water-cooled condensation pipe 6, an oil-gas separator 7 and a collector, and there are more than one reaction chamber 1 and more than one The combustion chambers 2 are independent from each other and are separated and staggered. The partition plate 8 between the reaction chamber 1 and the combustion chamber 2 is made of heat-conducting material, and a temperature control valve 15 is also connected between the reaction chamber and the combustion chamber. The lower end of each combustion chamber 2 is a fuel inlet 9, and the upper end is connected with a heat pipe 3, and the upper end of each reaction chamber 1 communicates with a collection branch pipe 5, and the collection branch pipe 5 communicates with the collection pipe 4 running through the center of the water-cooled condensation pipe 6, The end of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com