Laser cladding repairing method for cylinder sleeve

A technology of laser cladding and repairing method, which is applied in the field of repairing technology of hydraulic oil cylinder and hydraulic oil cylinder liner, can solve the problems such as the reduction of the movement accuracy of the oil cylinder and the conversion efficiency of the force, the shutdown of the mechanical system, and the roughening of the surface of the cylinder liner. The effect of reducing spare parts costs and wear, extending service life, and reducing the amount of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

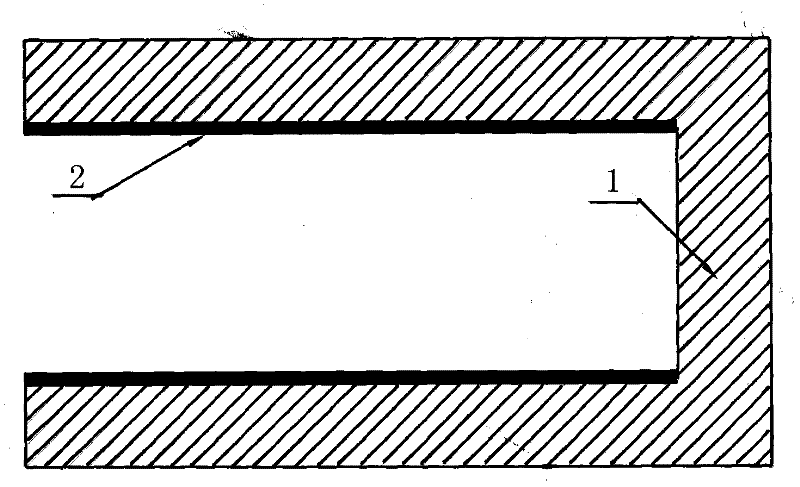

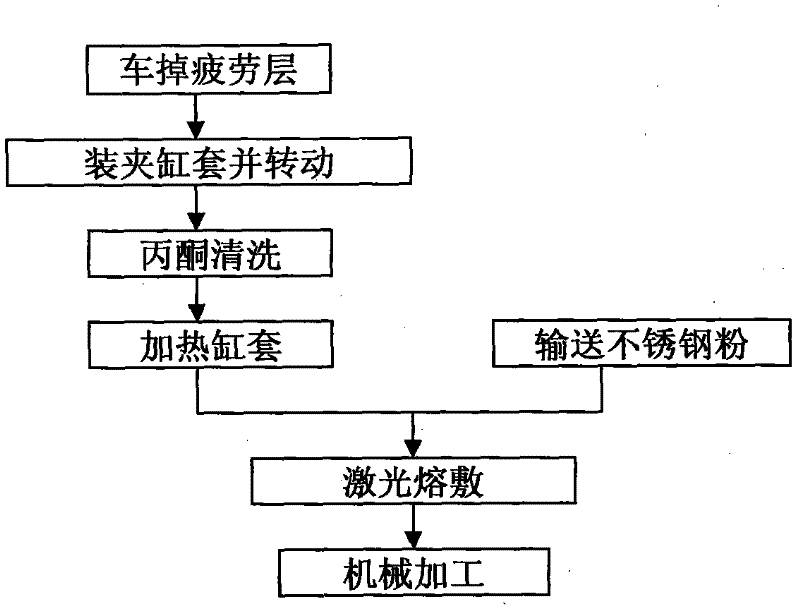

[0030] 1) Use a lathe to remove the 1mm metal fatigue layer of the body on the working surface of the waste hydraulic cylinder liner 1;

[0031] 2) Install the cylinder liner 1 on the fixture, and rotate the fixture at a linear speed of 600mm / min;

[0032] 3) Pour acetone on the working surface of cylinder liner 1 to clean off oily impurities;

[0033] 4) Heat the cylinder liner from 1 to 60°C with an alcohol blowtorch;

[0034] 5) Conveying the martensitic stainless steel powder to the working surface of the cylinder liner 1;

[0035] 6) Irradiate the martensitic stainless steel powder with a laser power of 3.5KW and a bandwidth of 3mm to melt it, and deposit a stainless steel surface layer 2 with a thickness of 3mm;

[0036] 7) Remove the cylinder liner from the fixture, and machine the cylinder liner size and roughness to meet the use size specifications.

Embodiment 2

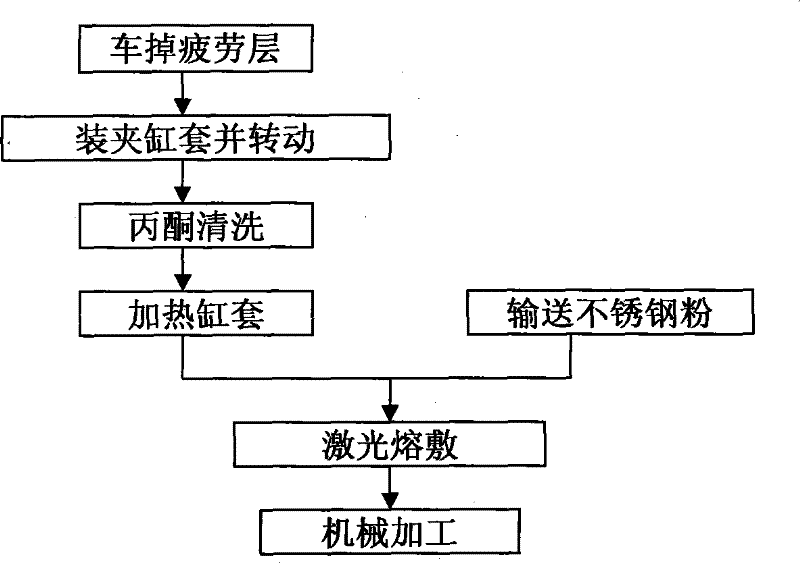

[0038] 1. Use a lathe to remove the 2mm metal fatigue layer of the main body on the working surface of the waste hydraulic cylinder liner 1;

[0039] 2. Install the cylinder liner 1 on the fixture, and turn the fixture at a linear speed of 700mm / min;

[0040] 3. Pour acetone on the working surface of the cylinder liner 1 to clean off the oil and impurities;

[0041] 4. Heat the cylinder liner from 1 to 100°C with an alcohol blowtorch;

[0042] 5. Deliver martensitic stainless steel powder to the working surface of cylinder liner 1;

[0043] 6. Irradiate the martensitic stainless steel powder with a laser power of 3.5KW and a bandwidth of 3mm to melt it, and deposit a stainless steel surface layer 2 with a thickness of 7.3mm;

[0044] 7. Remove the cylinder liner from the fixture, and machine the cylinder liner size and roughness to meet the use size specifications.

[0045] Example 2:

[0046] (1). Use a lathe to remove the 0.5mm body metal fatigue layer on the working sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com