Crack initiation and expansion method in restraint structural component based on laser shock peening

A technology of laser shock strengthening and expansion method, which is applied in the field of repairing metal structural parts, can solve the problem that the fatigue life of structural parts cannot be well guaranteed, and achieve the effects of preventing the initiation of micro-cracks, suppressing the formation of notch cracks, and rapidly repairing and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

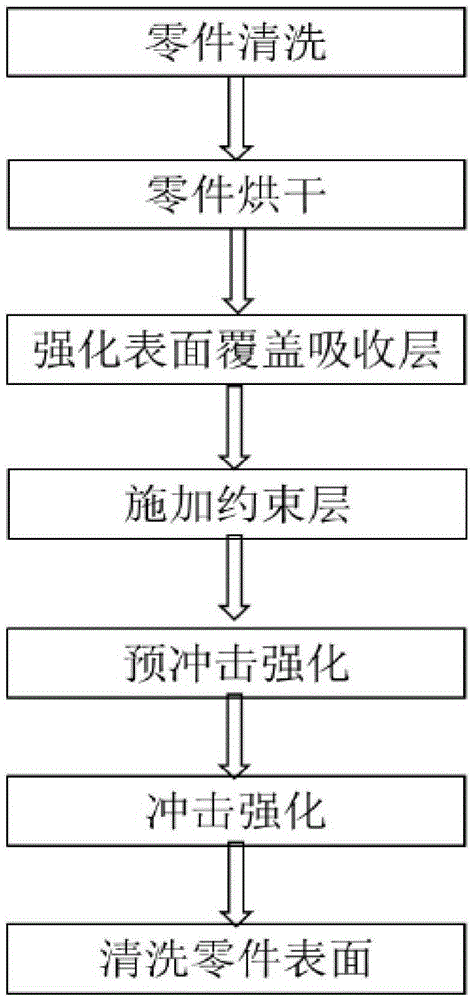

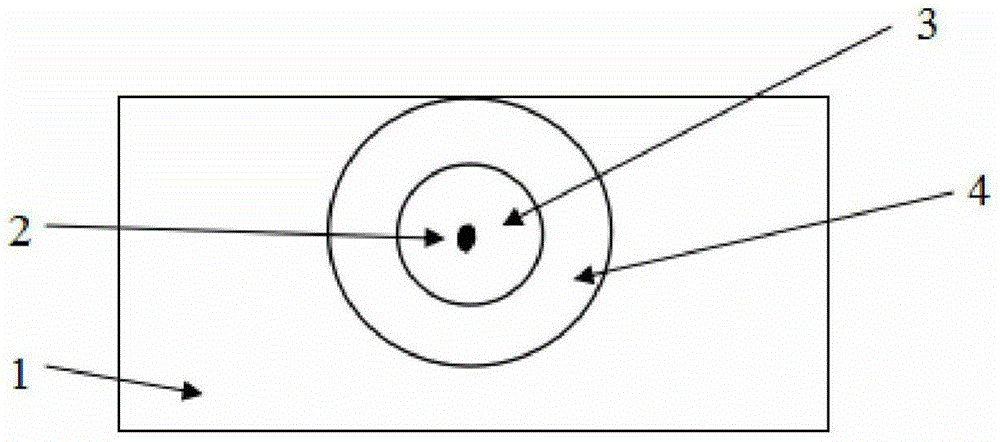

[0061] Specimen material (i.e. structural parts, such as Figure 3A , 3B Shown): 6082 aluminum alloy standard tension-compression fatigue specimen with a length of 55mm and a thickness of 3mm, with a 0.1mm-long scratch damage;

[0062] Before the strengthened surface of the structural part is covered with the absorbent layer, the structural part is placed in an ultrasonic cleaning machine with deionized water at a temperature of 22 ° C, and the ultrasonic frequency is 38 kHz, and cleaned for 15-20 minutes; Dry, and then put it in a drying oven at 70°C for 20 minutes.

[0063] Cover a layer of 120μm black tape on the surface of the titanium alloy structure, and then apply a 2mm deionized water confinement layer on the surface of the black tape. Pre-shock strengthening treatment: pulse width 12ns, wavelength 532nm, laser energy 5J, a laser beam with a repetition frequency of 2 Hz and a beam diameter of 2 mm is subjected to pre-shock strengthening treatment, where the overlap r...

Embodiment 2

[0066] Specimen material: 6082 aluminum alloy standard tension-compression fatigue specimen with a length of 55mm and a thickness of 3mm, with a notch damage of 0.05×0.05×0.05mm;

[0067] Before the strengthened surface of the structural parts is covered with the absorbent layer, put the structural parts into an ultrasonic cleaning machine with deionized water at a temperature of 24°C and an ultrasonic frequency of 47kHz for 20 minutes; Dry in a drying oven at 70°C for 20 min.

[0068] Cover a layer of 120μm black tape on the surface of the titanium alloy structure, and then apply a 2mm deionized water confinement layer on the surface of the black tape. Pre-shock strengthening treatment: pulse width 12ns, wavelength 532nm, laser energy 5J, a laser beam with a repetition frequency of 2 Hz and a beam diameter of 2 mm is subjected to pre-shock strengthening treatment, where the overlap rate is 30%, and the impact is 1 time. Then, a laser beam with a pulse width of 12 ns, a wavel...

Embodiment 3

[0071] Specimen material: 6082 aluminum alloy standard tension-compression fatigue specimen with a length of 55mm and a thickness of 3mm, pit corrosion with a diameter of 0.09mm and a depth of 1mm;

[0072] Before the strengthened surface of the structural parts is covered with the absorbent layer, put the structural parts into an ultrasonic cleaning machine with deionized water at a temperature of 24°C and an ultrasonic frequency of 47kHz for 20 minutes; Dry in a drying oven at 70°C for 20 min.

[0073] Cover a layer of 120μm black tape on the surface of the titanium alloy structure, and then apply a 2mm deionized water confinement layer on the surface of the black tape. Pre-shock strengthening treatment: pulse width 12ns, wavelength 532nm, laser energy 5.5J, a laser beam with a repetition rate of 2 Hz and a beam diameter of 2 mm is subjected to pre-shock strengthening treatment, and the overlap rate is 30%, and the impact is 1 time. Then, a laser beam with a pulse width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com