Main machine of closed cycle boiling dryer

A boiling dryer, closed-circuit technology, applied in drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of high labor intensity, waste of time, low efficiency, etc., to achieve low work intensity, easy operation, High thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

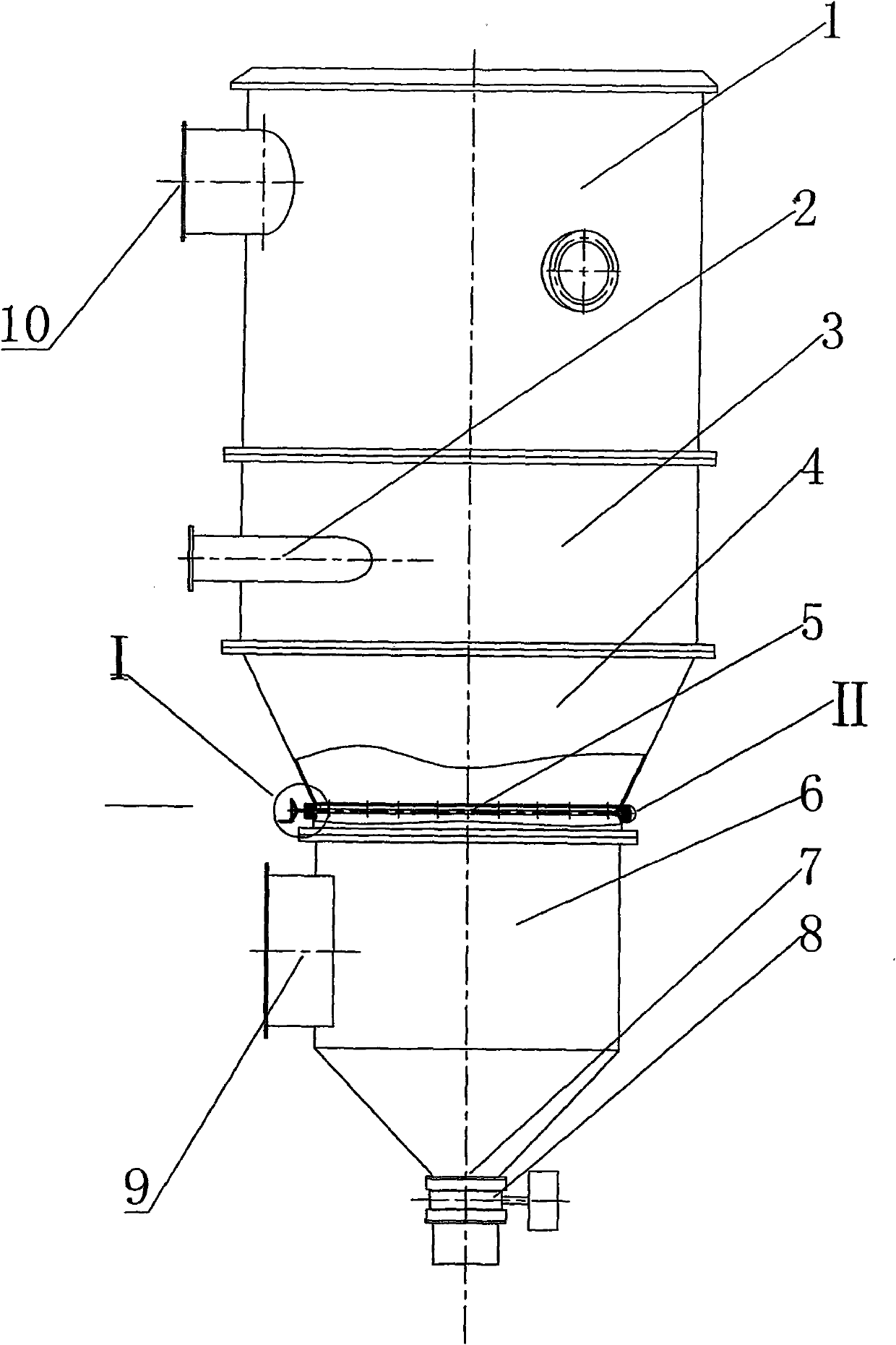

[0021] see figure 1 , The main body of the closed-circuit circulation fluidized dryer involved in the present invention is mainly composed of an upper cylinder 1 , a middle cylinder 3 , a hopper 4 , a lower cylinder 6 and an orifice plate or a sintered mesh plate 5 . The upper cylinder 1, the middle cylinder 3, the hopper 4 and the lower cylinder 6 are connected vertically from top to bottom, and the orifice plate or sintered mesh plate 5 is connected to the bottom of the hopper 4 transversely. One side of the middle cylinder 3 is provided with a feed port 2, one side of the lower cylinder 6 is provided with an air inlet 9, the bottom is connected with a discharge port 7, the bottom of the discharge port 7 is provided with a discharge valve 8, and the upper cylinder is 1 is provided with an air outlet 10 on one side.

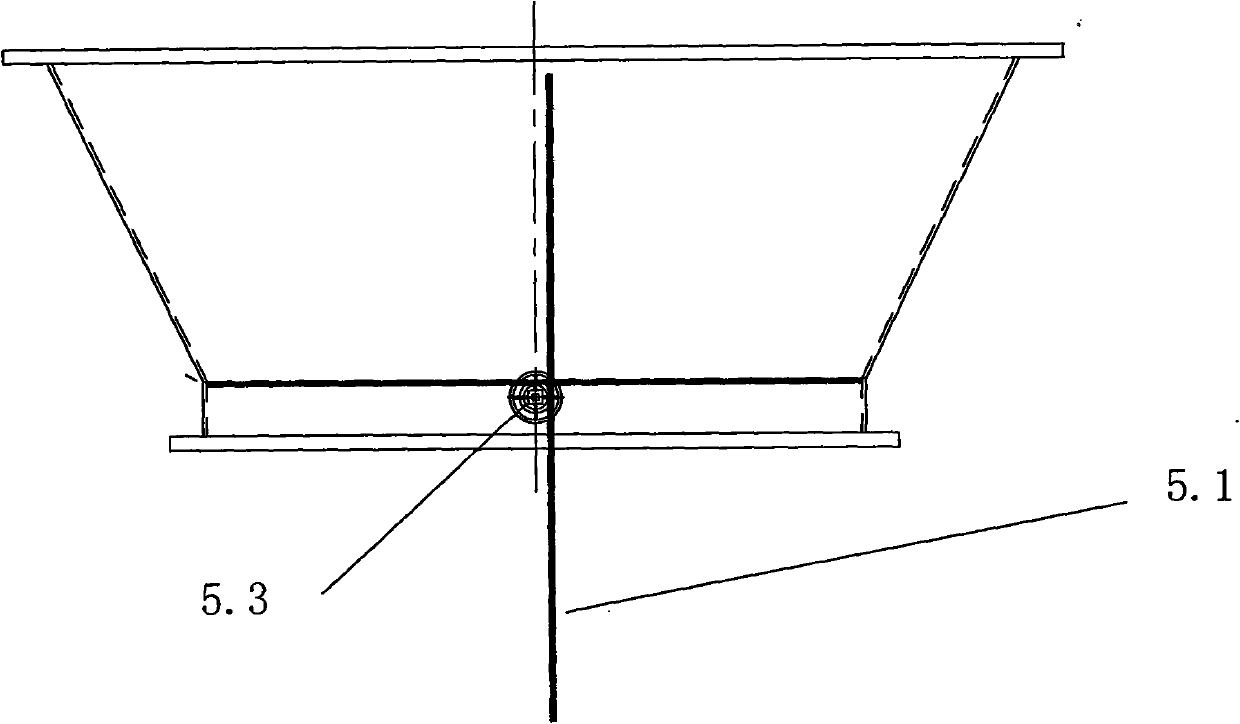

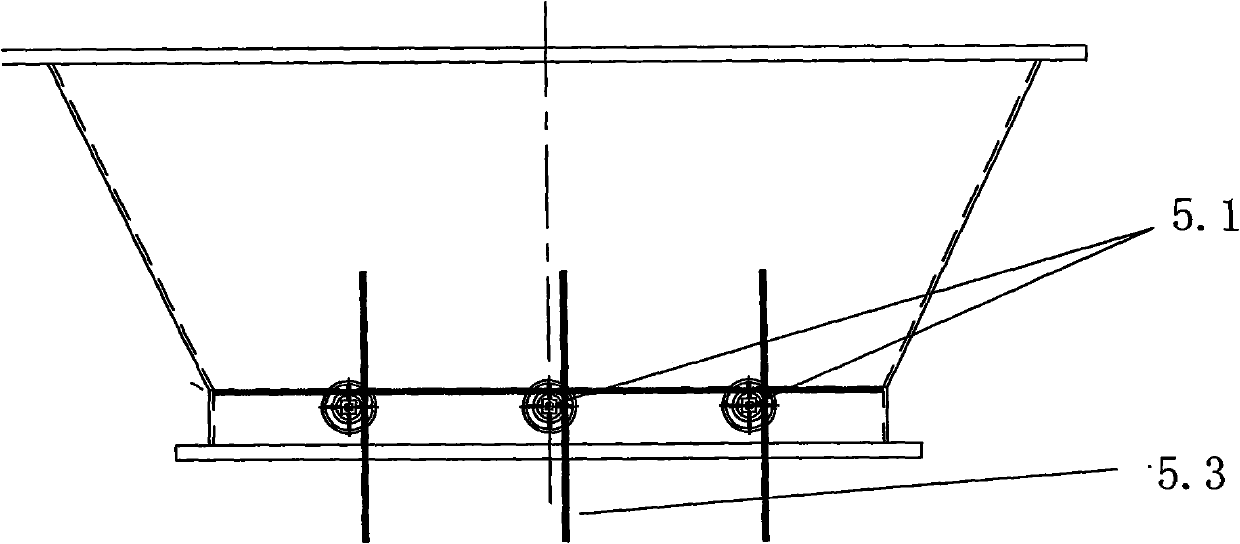

[0022] see Figure 2-5 , the orifice or sintered mesh plate 5 is made into an overturned structure, consisting of an overturning shaft 5.3, an orifice or sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com