Filling control method of semiconductor production lines

A control method and production line technology, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problem of not being able to respond well to various emergencies, and achieve improved efficiency, simple design process, and predictive ability. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

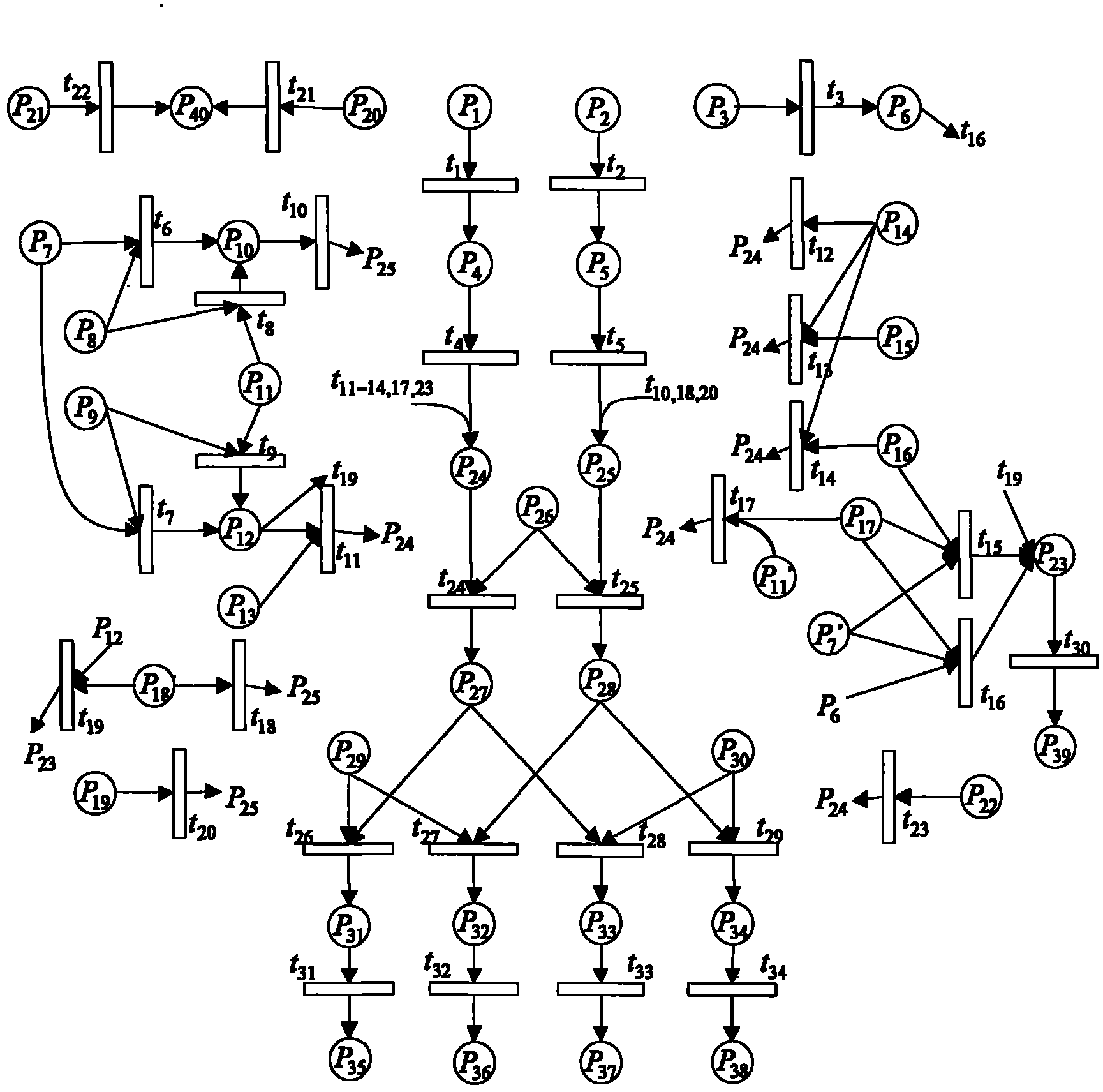

[0039] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further introduced below in conjunction with the accompanying drawings.

[0040] Taking a semiconductor production line model as the object, the feeding control research is carried out. On the eM-Plant simulation platform, the simulation calculation is performed 24 hours a day, and the simulation time is 1 year.

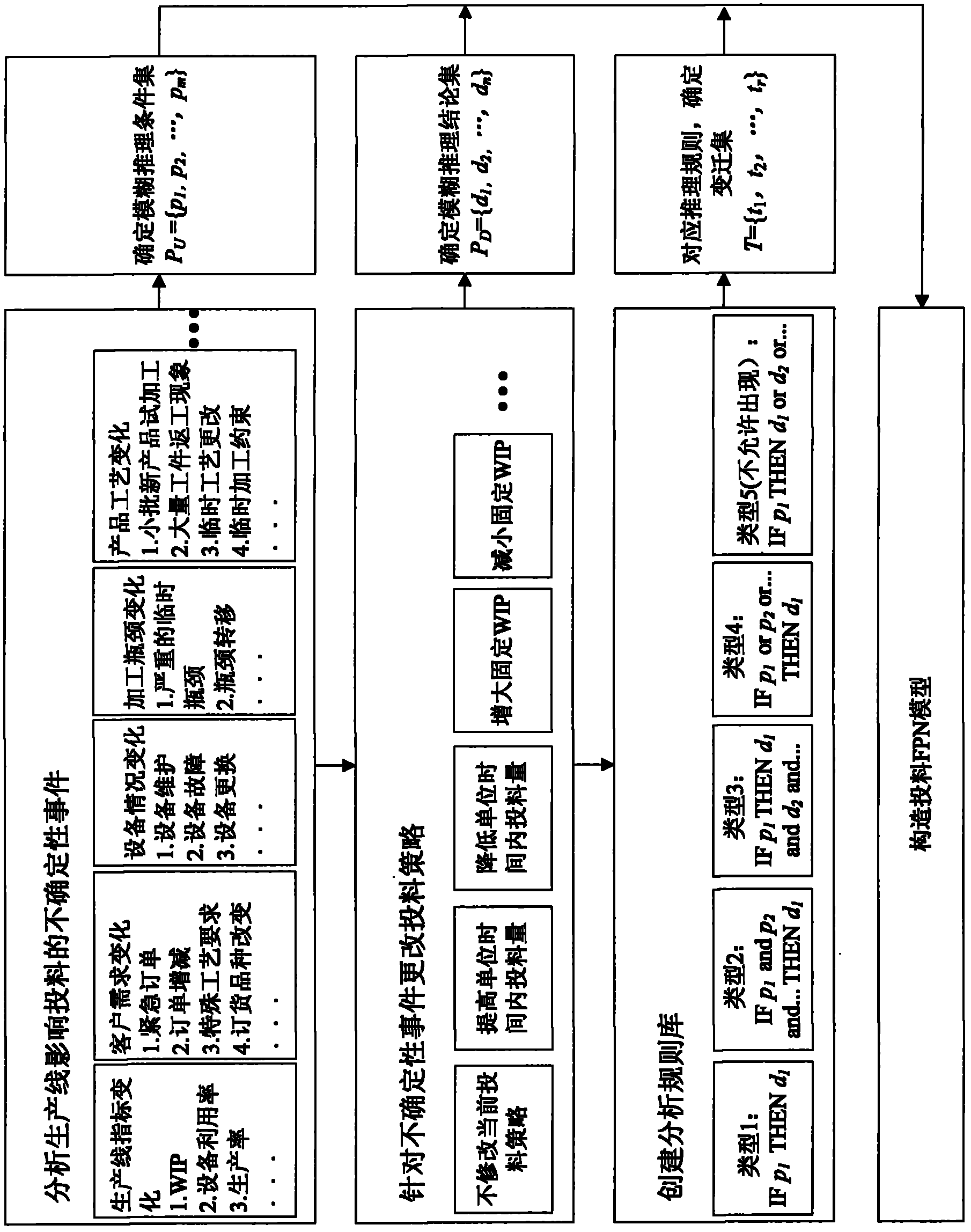

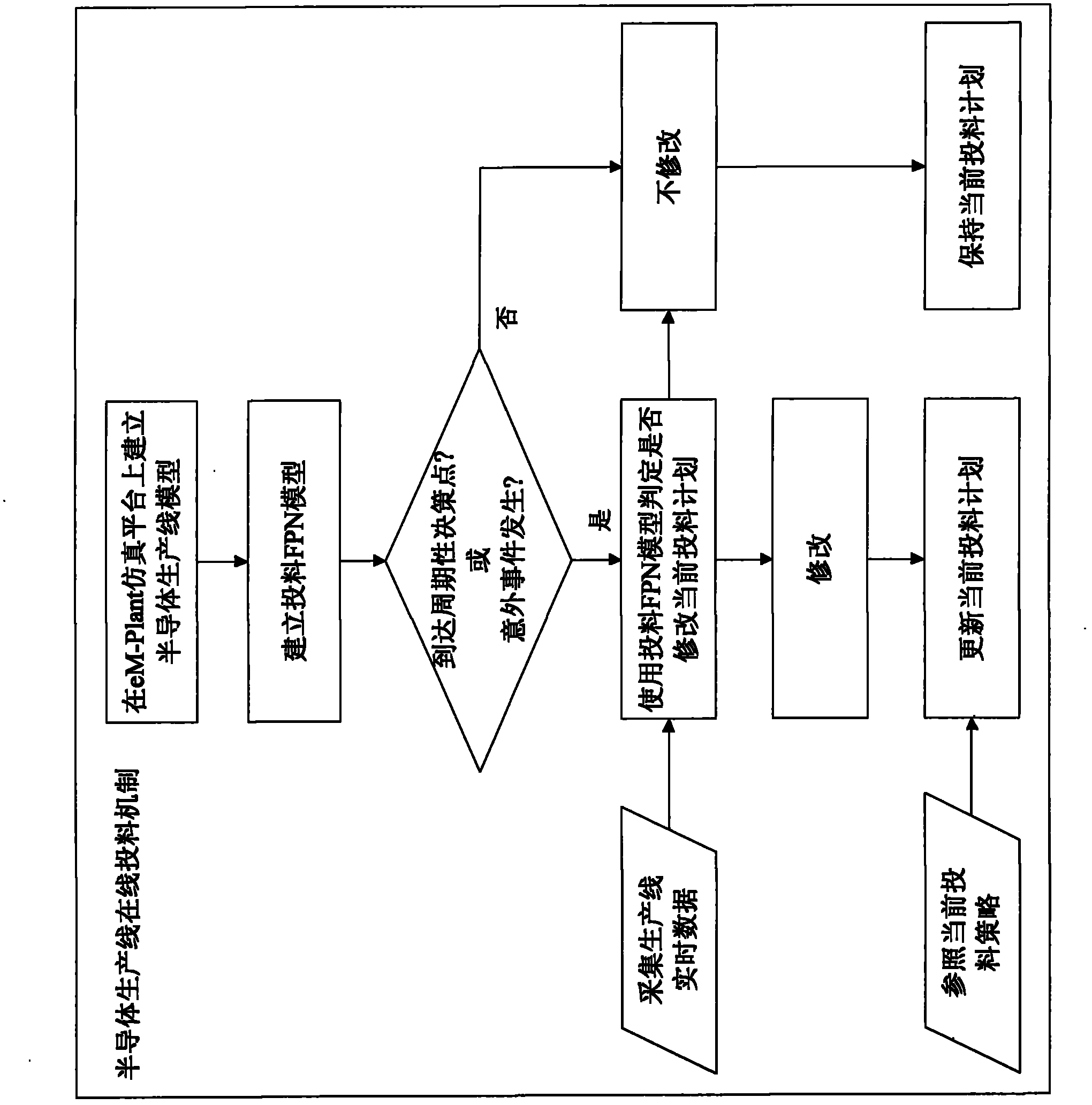

[0041] see figure 1 As shown, it is a schematic diagram of the fuzzy Petri net modeling process of semiconductor production line feeding in the present invention. figure 2 It is a structural schematic diagram of the online feeding mechanism of the semiconductor production line in the present invention.

[0042] Through experimental analysis, the following decision rules can be extracted:

[0043] 1. If the average WIP is much higher than the set value (empirical average WIP) when the bottleneck equipment is fully loade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com