Single mandril spoke type superconductive accelerating cavity and manufacture method thereof

A superconducting accelerating cavity and spoke-type technology, which is applied in the direction of manufacturing tools, linear accelerators, metal processing equipment, etc., can solve the problems of narrow electromagnetic field energy storage space, limiting the stability of the acceleration gradient of superconducting cavity, etc., to improve the shape, The effect of reducing the possibility of thermomagnetic quenching and reducing the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

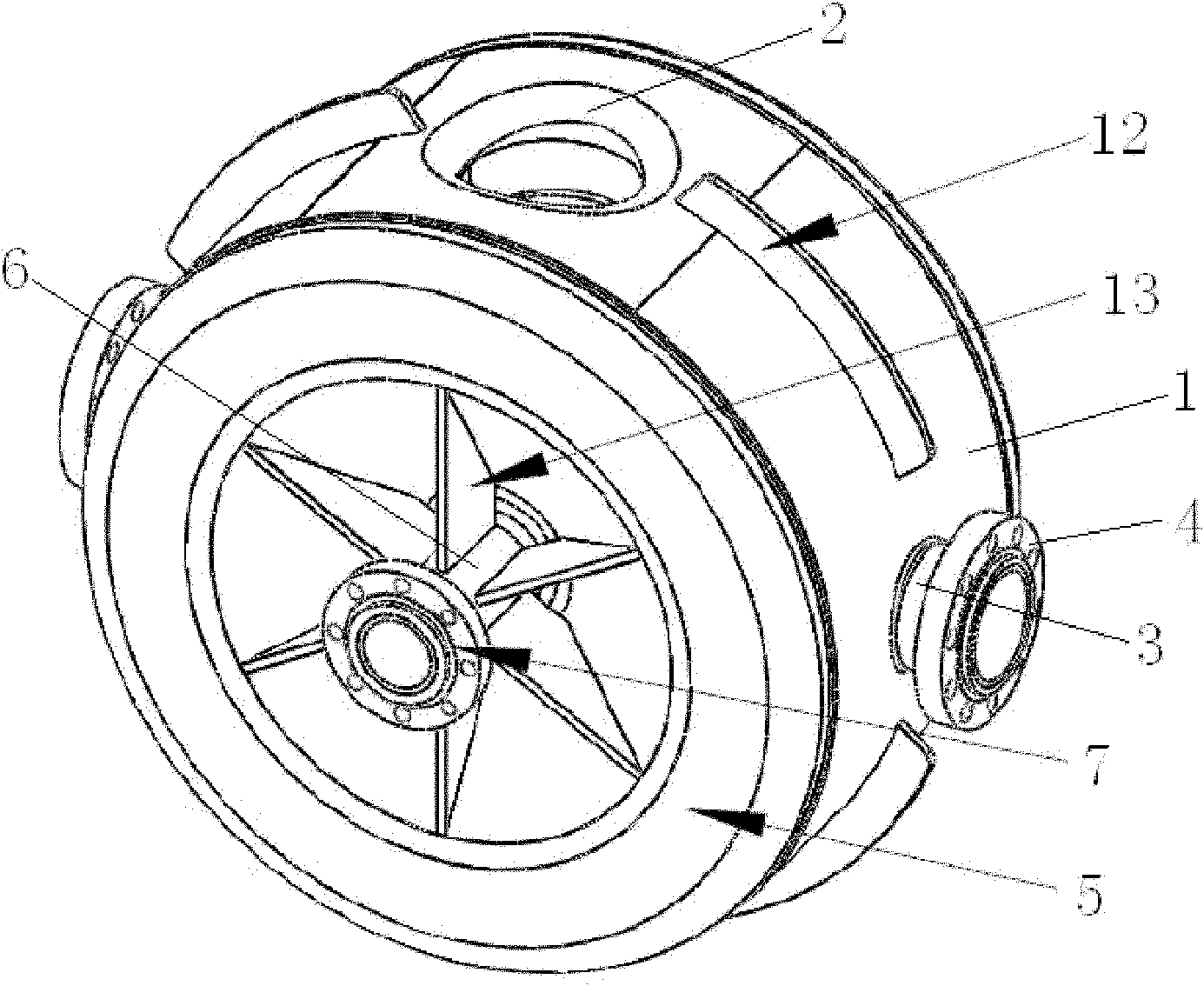

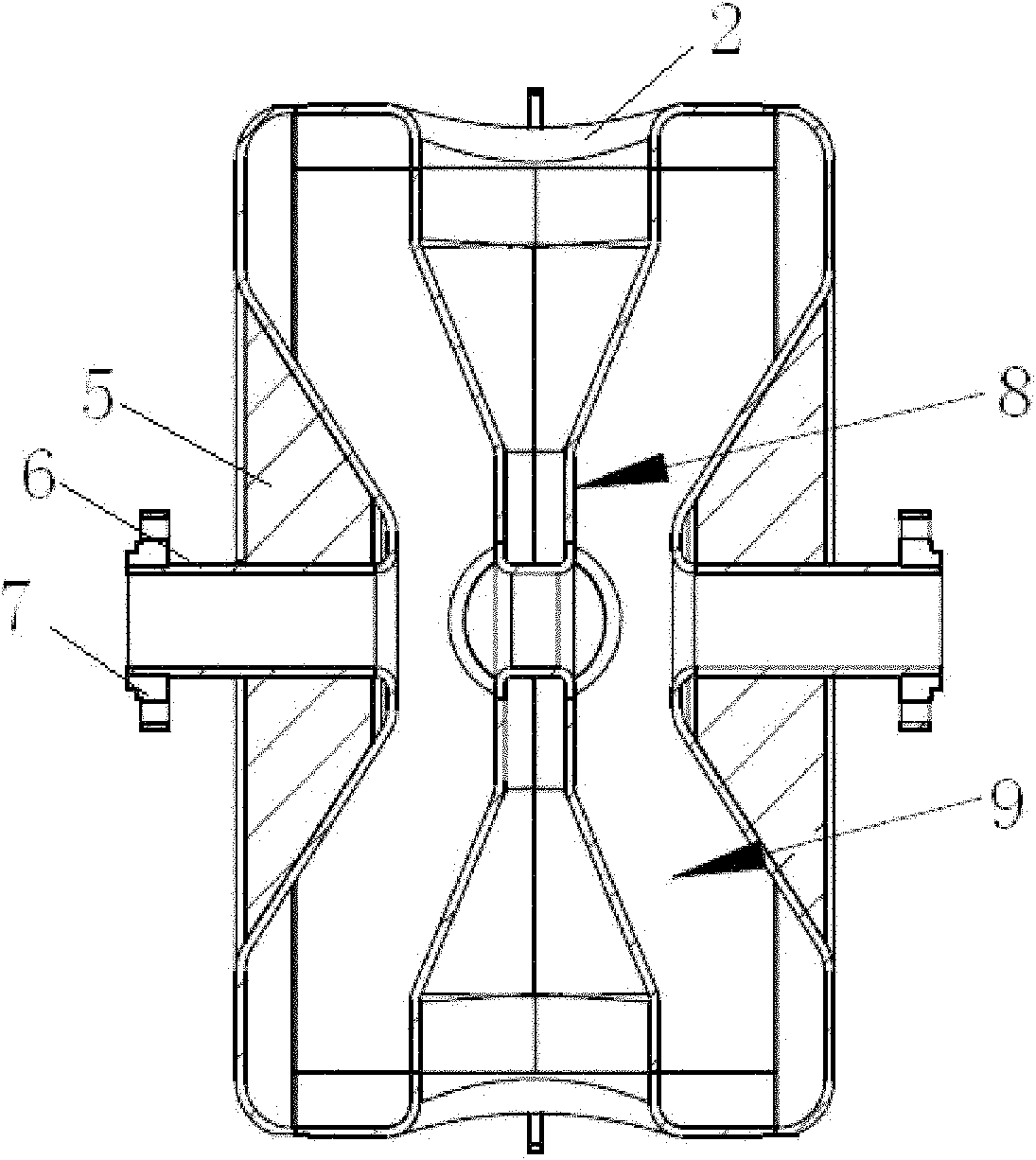

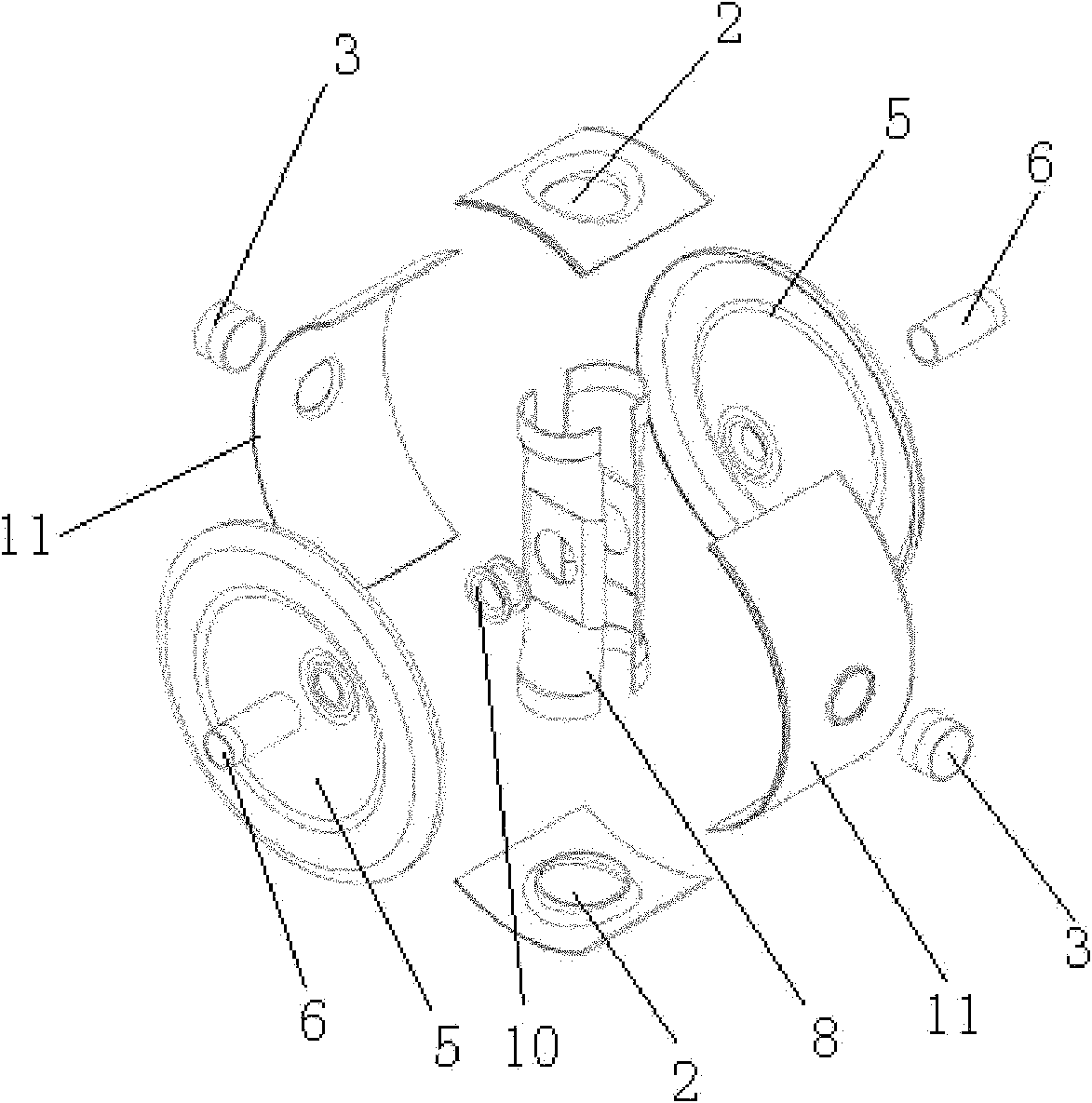

[0016] Such as figure 1 , figure 2 As shown, the present invention includes a cylindrical chamber 1, and the chamber 1 is composed of two symmetrically arranged saddle transition surfaces and two symmetrically arranged side surfaces. Two symmetrically arranged saddle transition surfaces are respectively provided with a mandrel hole 2, and two symmetrically arranged side surfaces are respectively provided with a cleaning hole. The two cleaning holes are respectively connected to a cleaning pipe 3. Connect to a flange 4 . Both ends of the cavity 1 are respectively provided with end caps 5 , forming a cavity with the cavity 1 . The middle part of the surface of the two end covers 5 is concave, and a bundle tube hole is respectively arranged in the center part. The two bundle tube holes are respectively connected with an end cover bundle tube 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com