Copper-zinc alloy electroplating bath and plating method using same

A technology of zinc alloy and electroplating, which is applied in transportation, packaging, thin material treatment, etc., can solve the problems of high toxicity, heavy burden of cyanide-containing waste liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

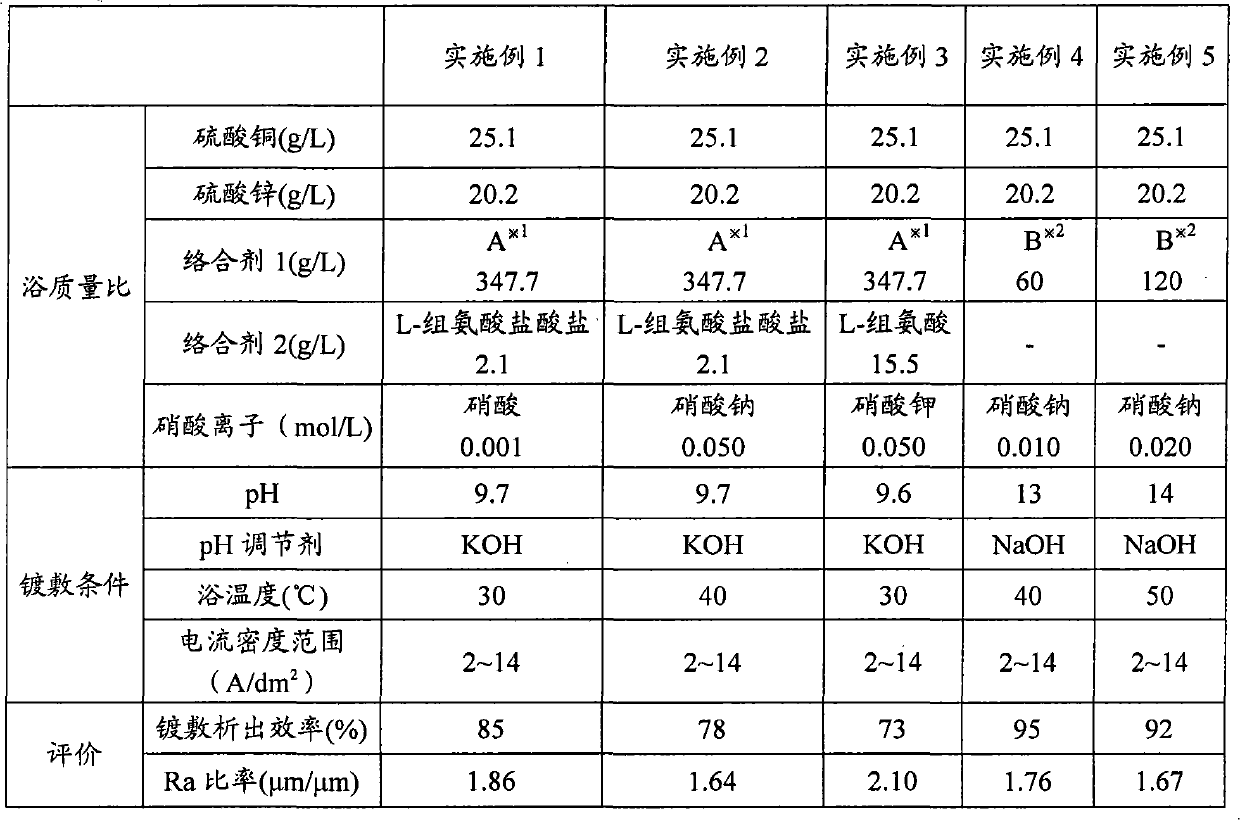

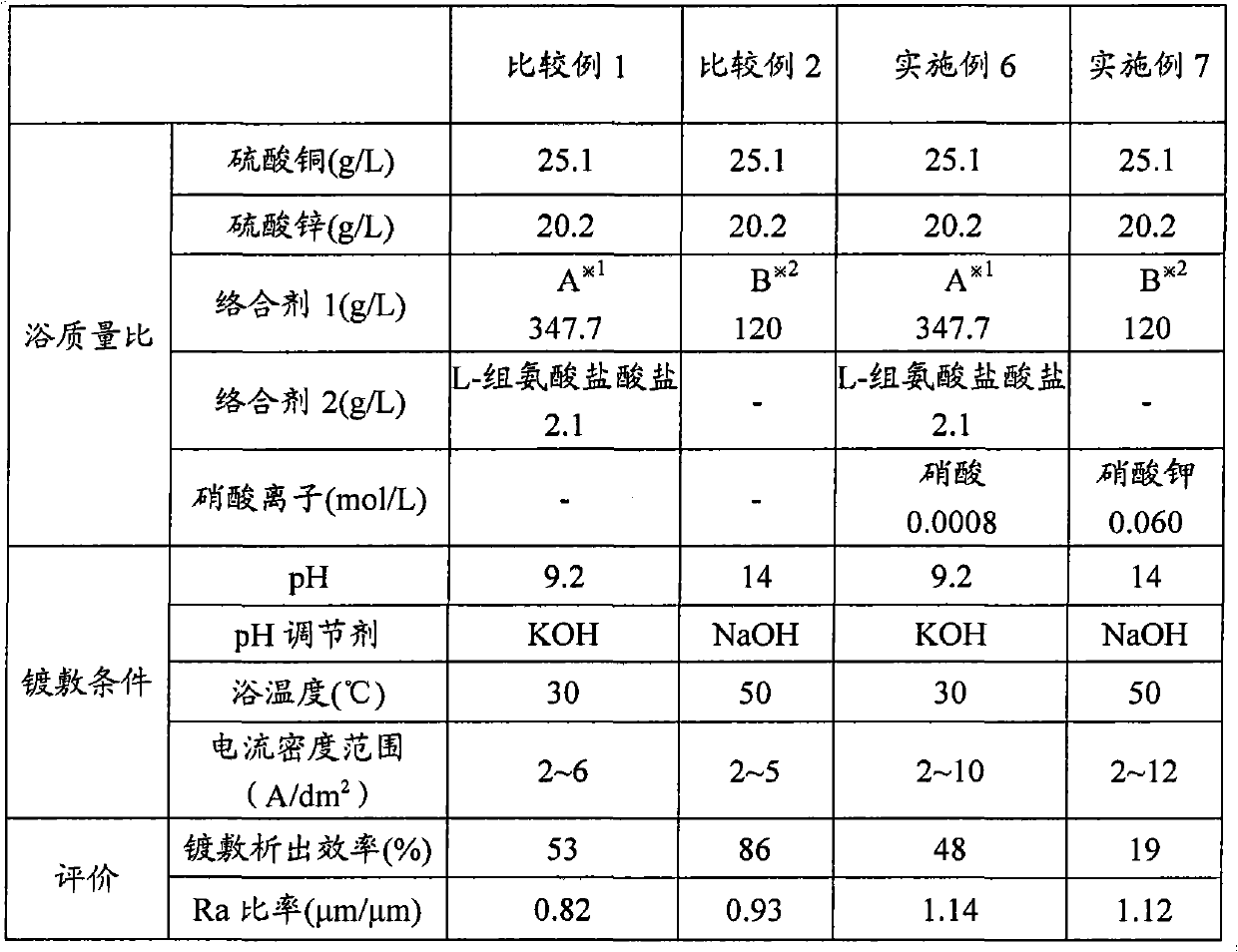

[0040] (Examples 1 to 7, Comparative Examples 1 and 2)

[0041] According to the composition of the copper-zinc alloy electroplating bath shown respectively in the following Tables 1 and 2, the copper-zinc alloy electroplating baths of Examples 1 to 7 and Comparative Examples 1 and 2 were prepared according to the following Tables 1 and 2. The plating conditions shown are copper-zinc alloy plating treatment. The evaluation of the plating bath used the plating deposition efficiency and the Ra ratio. The obtained results are collectively shown in Tables 1 and 2 below.

[0042]

[0043] The plating deposition efficiency represents the ratio of the actual deposition amount to the theoretical deposition amount in percentage. The larger the value, the smaller the amount of hydrogen generation, and it is possible to form a uniform and glossy plating layer, and it also means that there is less energy loss and the productivity of the plating layer is excellent.

[0044]

[0045] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com