Processing method for reducing astringent taste of red tea

A processing method and technology of bitterness and astringency, applied in the field of processing to reduce the bitterness and astringency of black tea, to achieve the effect of improving quality, simple operation, and increasing alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

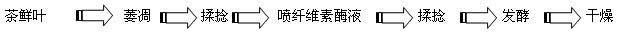

[0013] 1. Place the fresh leaves of the tea tree wither in a room with normal temperature and low humidity.

[0014] 2. Knead until the withered leaves lose about 35%-40% of their weight.

[0015] 3. Knead the withered leaves until they are initially slivered and stop rolling, and evenly spray cellulase solution with a concentration of 1% on the kneaded leaves. The sprayed liquid / leaf mass ratio is 1:8-1:10. After the end, continue to knead until the tea sticks are tightly rolled, the tea juice overflows, and the tea sticks turn yellow.

[0016] 4. Move the kneaded leaves to the fermentation room for fermentation. The fermentation time is 1.5-3 hours. After the fermentation is completed, it is dried to make finished tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com