Dry method desorption device for organic waste gas activated carbon adsorption

A technology for activated carbon adsorption and organic waste gas, applied in separation methods, combustible gas purification, chemical instruments and methods, etc., can solve problems affecting desorption efficiency, increasing production costs, affecting adsorption performance, etc., and achieve the effect of avoiding the decline of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

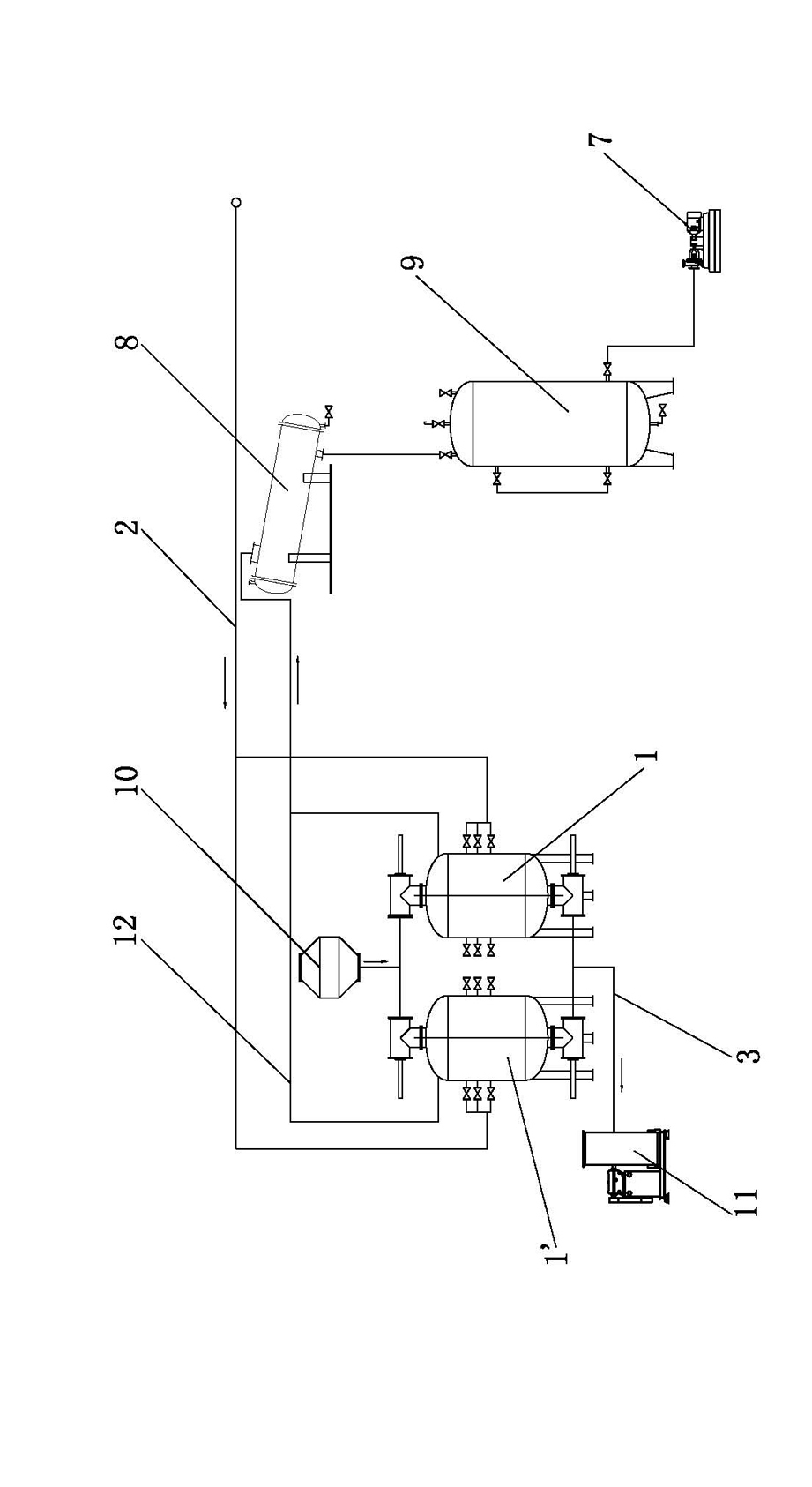

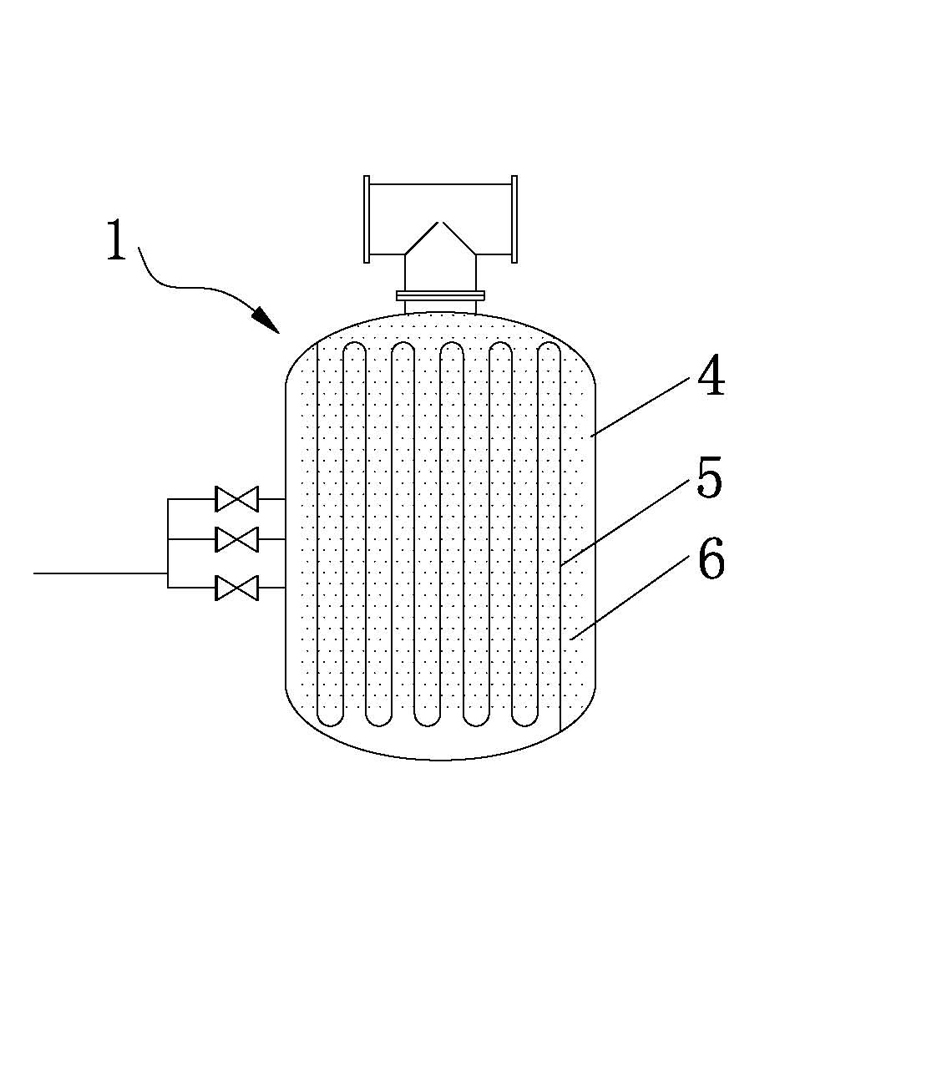

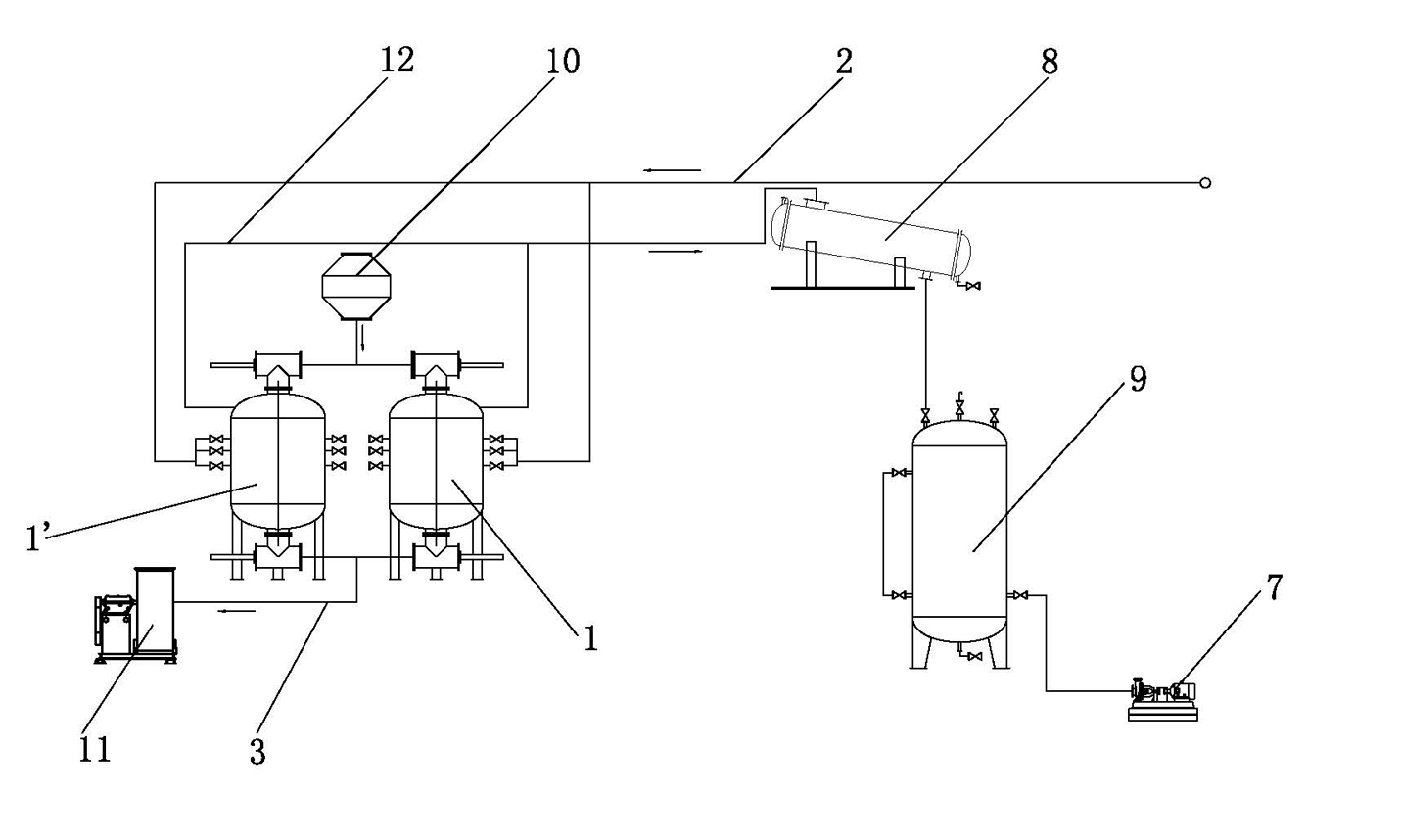

[0018] Such as figure 1 A dry-process desorption device for activated carbon adsorption of organic waste gas is shown, which includes a plurality of adsorption tanks 1 filled with activated carbon 6 arranged in parallel, a waste gas delivery channel 2 for transporting organic waste gas, and a channel for transporting purified gas. Clean gas delivery channel 3, a steam generating device for producing high-temperature desorption steam, and a solvent recovery device for collecting desorption solvent.

[0019] The exhaust gas delivery channel 2, the adsorption tank 1, and the clean gas delivery channel 3 constitute the adsorption part; the steam generating device (not shown in the figure), the adsorption tank 1 and the solvent recovery device constitute the desorption part. The adsorption tank 1 is provided with a waste gas pipe 4 for flowing through the organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com