Automatic anti-folding device for tractor-semitrailer

A technology for folding devices and automobiles and trains, applied in the direction of mechanical brake transmission devices, brakes, etc., can solve the problems of not being widely used in practical applications, insufficient real-time and accurate control, high energy consumption of anti-folding devices, etc., to meet the requirements of hanging and hanging Transportation requirements, ease of repair and replacement, and the effect of preventing folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0045] In the following examples: STC89S52 is used for the microcontroller, ADC0831 is used for the ADC, KMI1-15 is used for the vehicle speed sensor, SP2801A502 is used for the steering wheel angle sensor, SP2821A502 is used for the fifth wheel angle sensor, 4V430 is used for the quick release solenoid valve, and 4V430 is used for the brake solenoid valve .

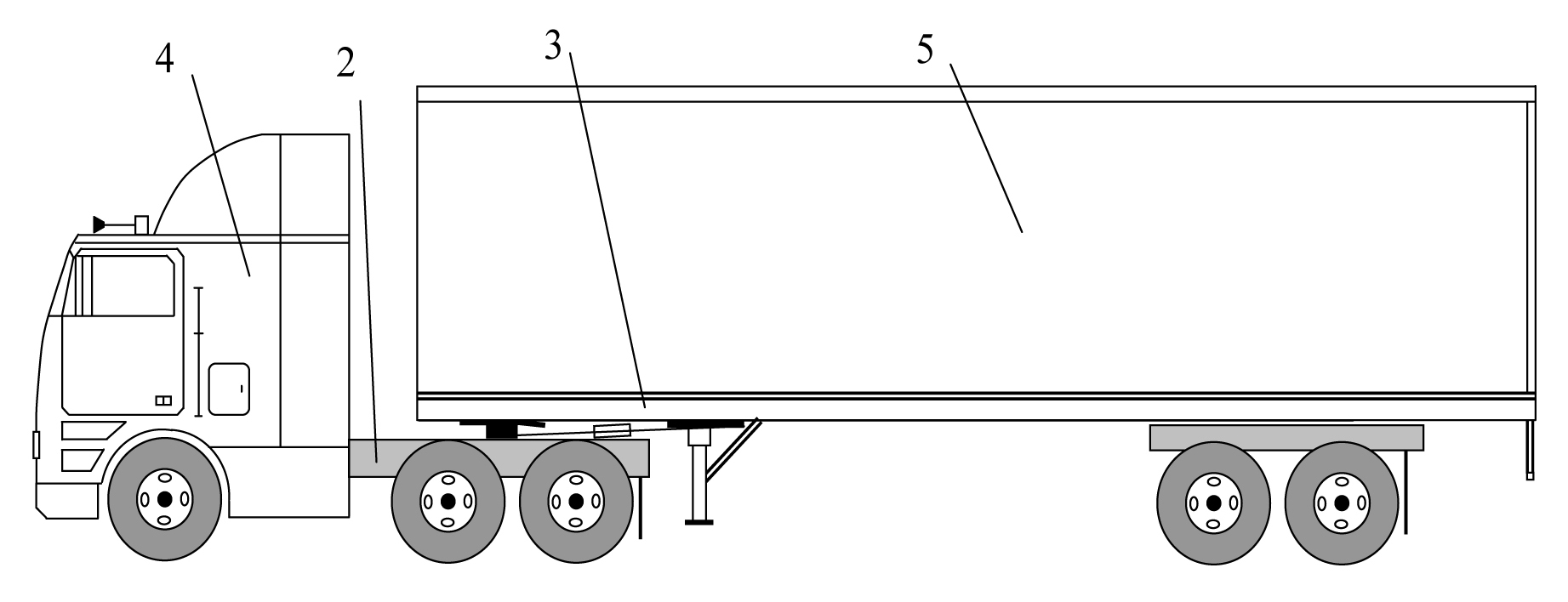

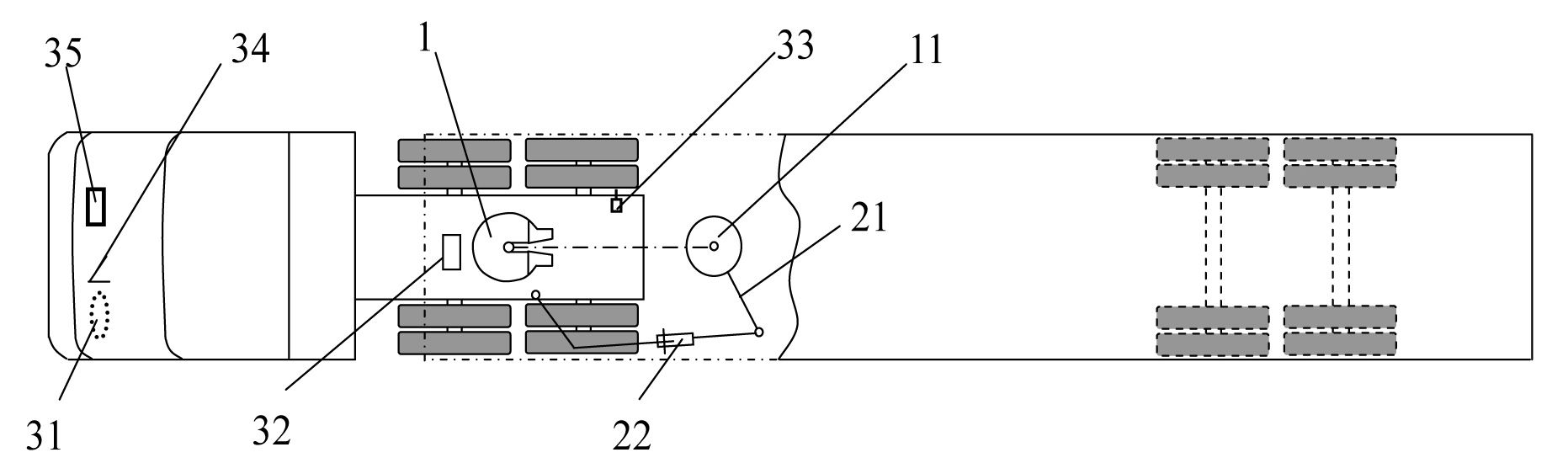

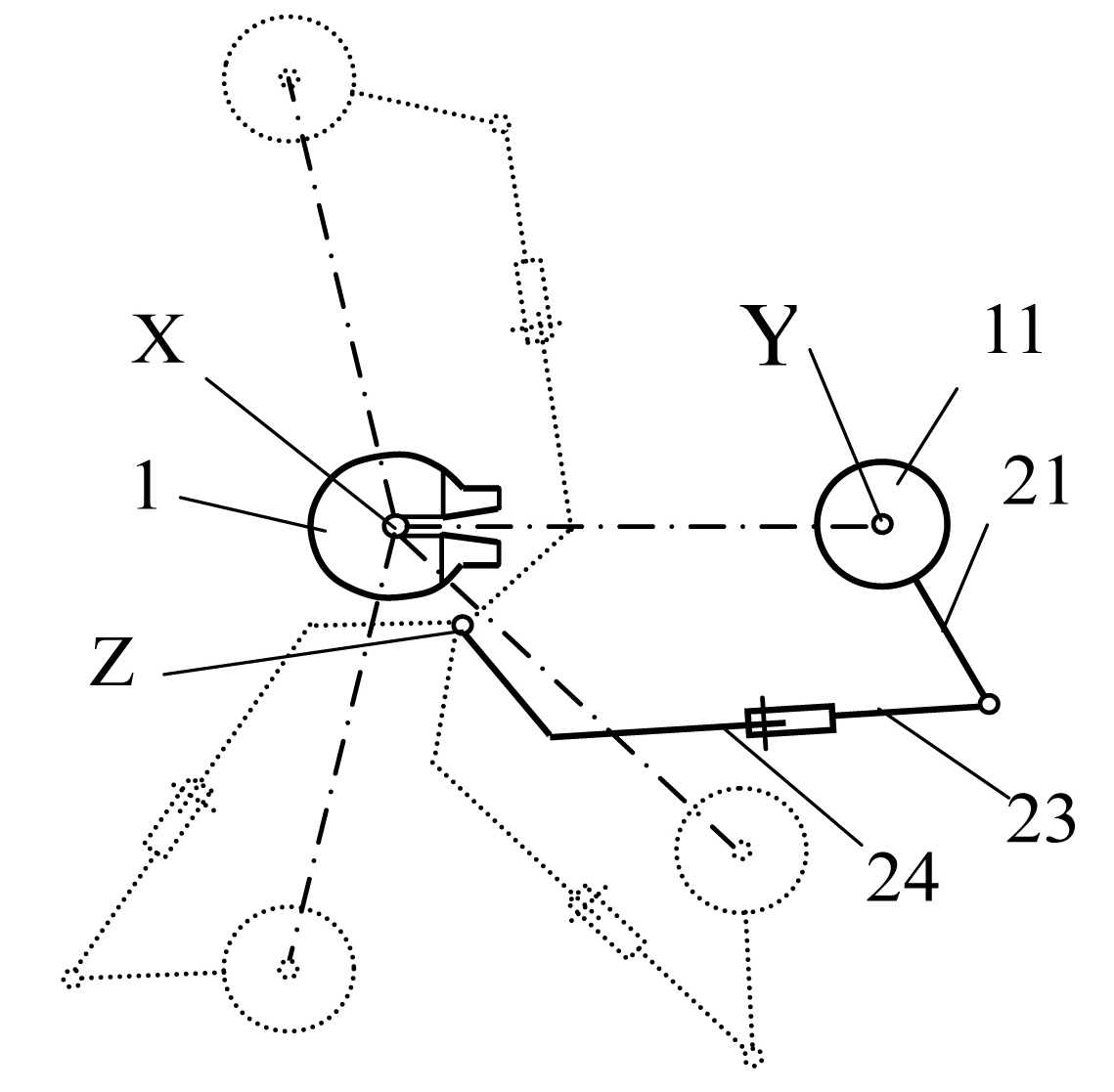

[0046] like Figure 1 to Figure 4 As shown, the automatic anti-folding device for semi-trailer trains of the present invention includes a cam drum brake 11, a crank linkage and a control system;

[0047] Described cam drum brake 11 is prior art, and it comprises brake shoe 12, brake camshaft 13, brake bottom plate 14, brake drum 15, brake air chamber 16 and return spring 17;

[0048] The crank-link mechanism is composed of a crank 21 and a combined connecting rod 22. The combined connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com