Method and device for regulating aggregate structure of thermoplastic semicrystalline polymer by using pulsed magnetic field

A pulsed magnetic field and polymer technology, applied in the field of regulating polymer aggregate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

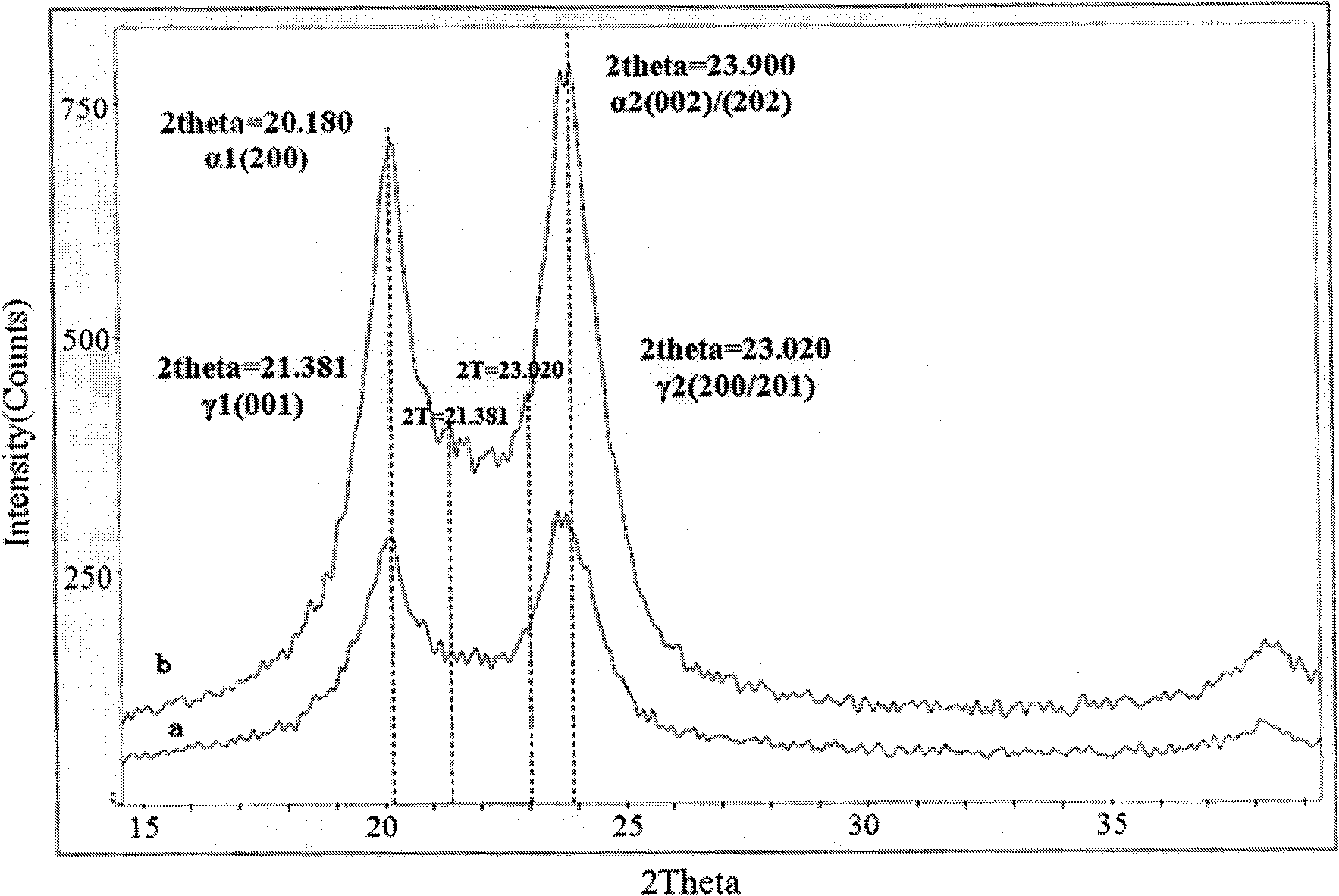

[0026] Embodiment one: non-pulse magnetic field processing polytrimethylene terephthalate (PTT) isothermal crystallization process, specifically adopt following technical scheme:

[0027] (a) Sample drying: The polymer raw material was dried at 130°C for 12 hours to fully remove moisture.

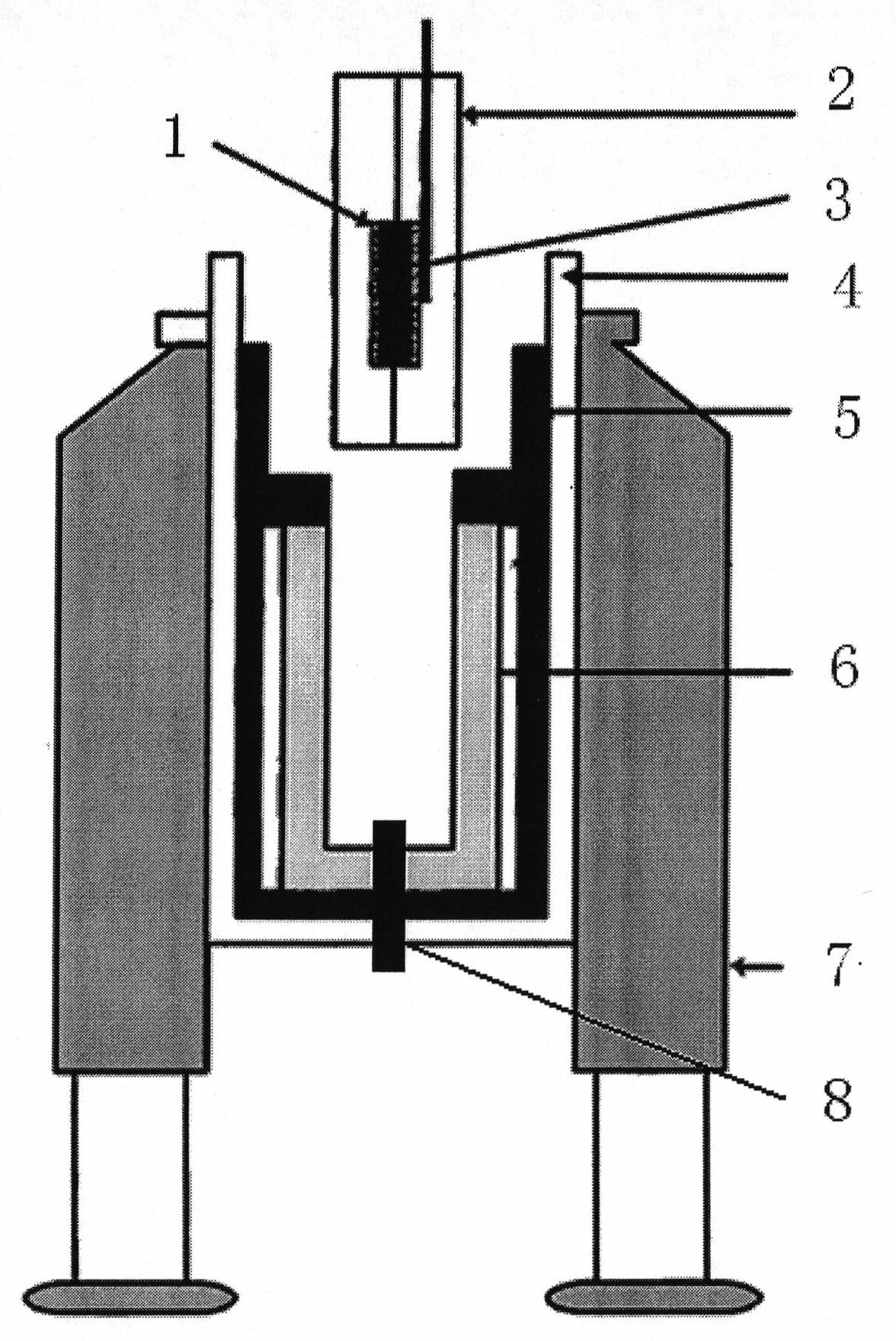

[0028] (b) Place the sample: place the sample in the 1-copper tube and fix it in the 2-sample furnace, then seal it and evacuate it, and protect it with argon.

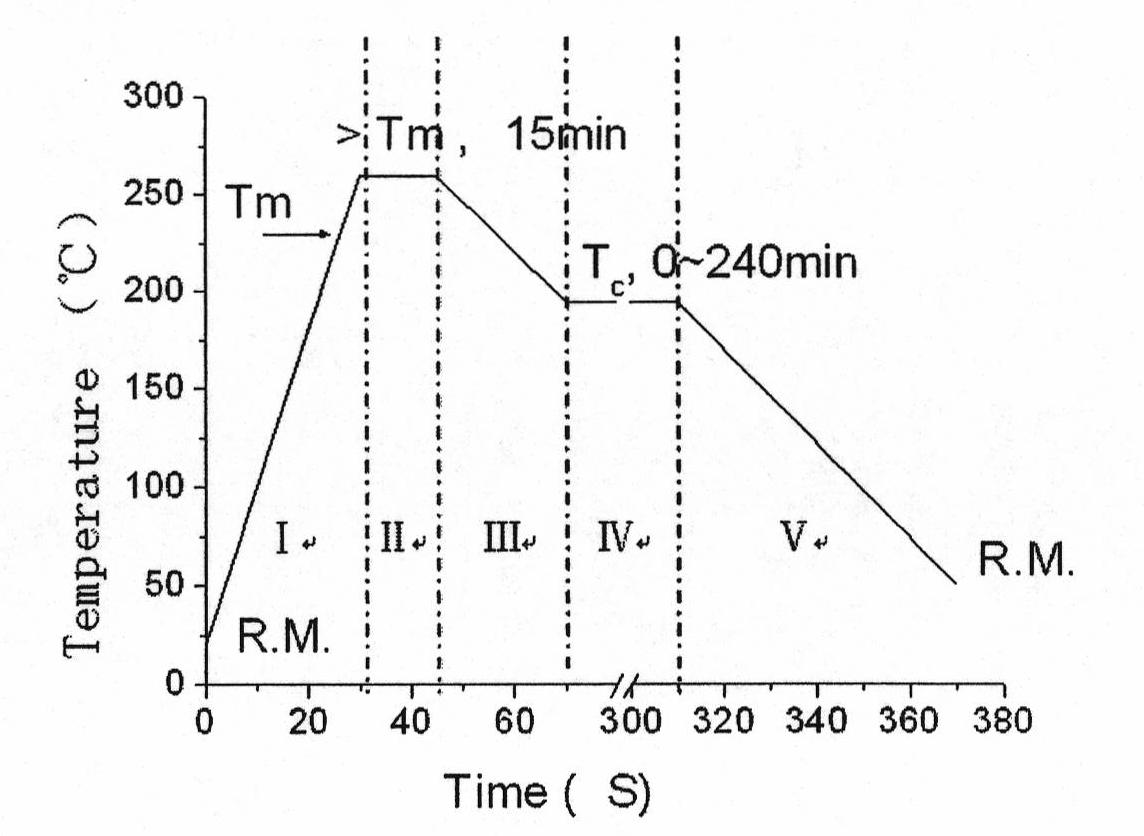

[0029] (c) Eliminate heat history: start from room temperature and heat at a rate of 10°C / min to about 260°C for 15 minutes.

[0030] (d) Isothermal crystallization: cooling to 195° C. for 60 minutes at a cooling rate of 5° C. / min.

[0031] (e) Cooling process: After the isothermal crystallization is completed, cool down to room temperature at a cooling rate of 5 °C / min, turn off all instruments and devices, and end the experiment.

Embodiment 2

[0032] Embodiment two: pulsed magnetic field condition: pulsed magnetic field intensity 1T; Magnetization frequency 2 times / minute; Whole course magnetic field treatment of isothermal crystallization process (such as figure 2 As shown, the I-V section area is magnetic). The polytrimethylene terephthalate (PTT) crystallization process specifically adopts the following technical scheme:

[0033] (a) Sample drying: The polymer raw material was dried at 130°C for 12 hours to fully remove moisture.

[0034] (b) Place the sample: place the sample in the 1-copper tube and fix it in the 2-sample furnace, then seal it and evacuate it, and protect it with argon.

[0035] (c) Adjust the intensity of the pulsed magnetic field to 1T; after the magnetization frequency is 2 times / minute, turn on the pulsed magnetic field device.

[0036] (d) Eliminate heat history: start from room temperature and heat at a rate of 10°C / min to about 260°C for 15 minutes.

[0037] (e) Isothermal crystalliz...

Embodiment 3

[0039] Embodiment 3: pulsed magnetic field conditions: pulsed magnetic field intensity 2T; magnetization frequency 2 times / minute; whole process of isothermal crystallization process with magnetic field treatment process polytrimethylene terephthalate (PTT) crystallization process, specifically adopt the technical scheme as described in embodiment 2 stated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com