Surface modified silicic acid semi-gels

A surface modification, semi-gel technology, applied in fibrous fillers, coatings, paper coatings, etc., can solve the problems of coating peeling, coating performance damage, re-destruction, etc., to achieve the effect of good connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

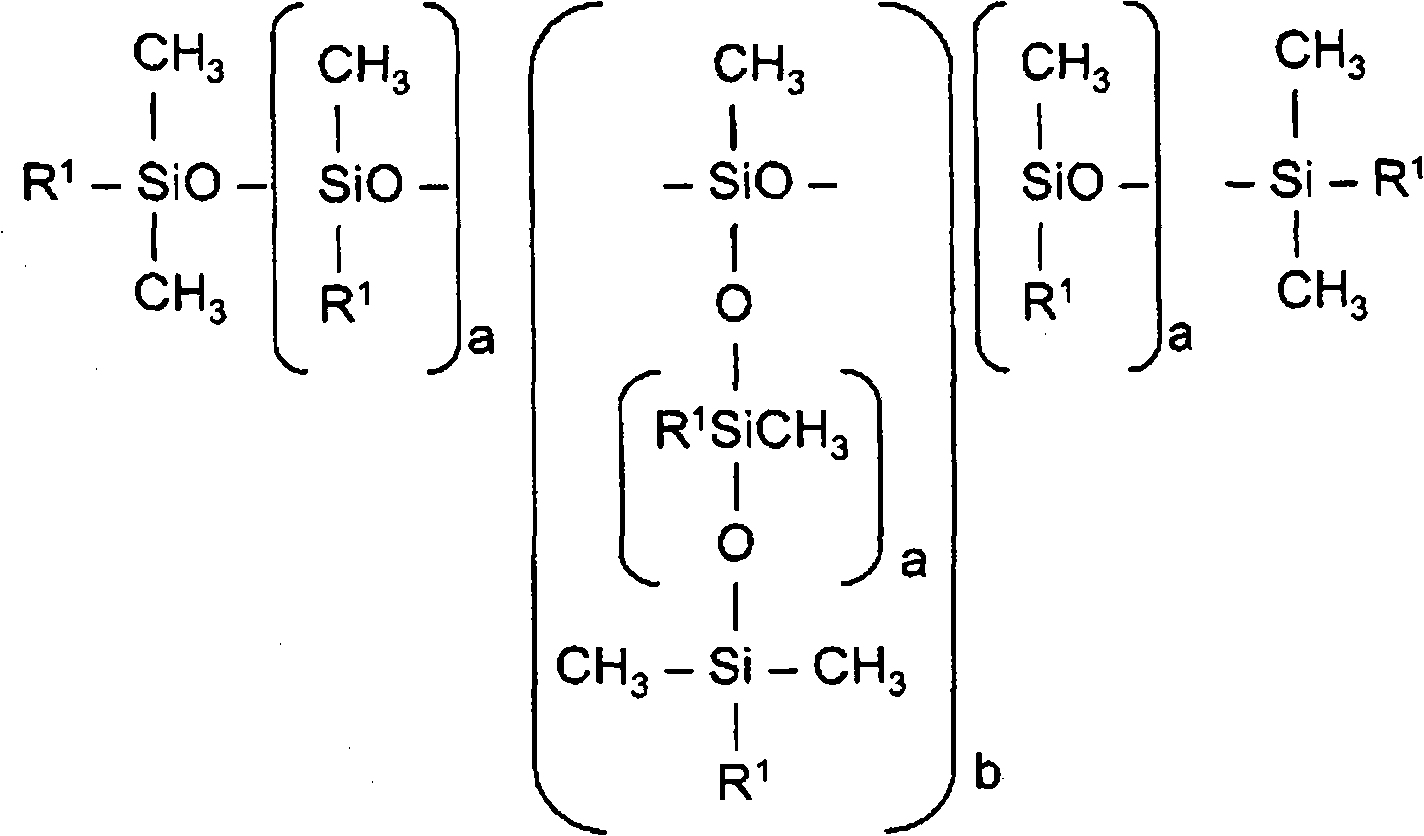

[0226] Semigel SD 500 with the following physical-chemical data according to Table 2, Beijing Aerospace Saide Powder Material Technology Co., Ltd., No. 16 Yuquan Road, Haidian District, Beijing, China, was carried out as follows by means of an AFG 50 jet mill from Alpine Corporation Grinding, and simultaneously coating with a suspension consisting of 50% by weight organopolysiloxane TegoRad 2300 and 50% by weight ethanol:

[0227] Rotation number of sorter: 15000 rpm

[0228] Sorting air: 30Nm 3 / h

[0229] Grinding pressure: 4 bar

[0230] PID blower: 51%

[0231] Total Air: 82Nm 3 / h

[0232] Material throughput: 0.57kg SiO2 / h

[0233] Grinding time: 80 minutes

[0234] The product was then dried in a drying oven at 80 °C for 2.5 h.

[0235] The addition of the TegoRad 2300 suspension was carried out such that a surface-modified semi-gel with the physico-chemical properties indicated in Table 2 was finally obtained.

Embodiment 2

[0237] Semi-gel SD 600 with the physico-chemical data shown in Table 2, Beijing Aerospace Saide Powder Material Technology Co., Ltd., No. 16 Yuquan Road, Haidian District, Beijing, China, was ground as follows by means of an AFG 50 jet mill from Alpine Corporation , and simultaneously coated with a suspension consisting of 50% by weight organopolysiloxane TegoRad 2300 and 50% by weight ethanol:

[0238] Rotation number of sorter: 15000 rpm

[0239] Sorting air: 30Nm 3 / h

[0240] Grinding pressure: 4 bar

[0241] PID blower: 51%

[0242] Total air: 79Nm 3 / h

[0243] Material throughput: 0.75kg SiO2 / h

[0244] Grinding time: 80 minutes

[0245] The product was then dried in a drying oven at 80 °C for 2.5 h.

[0246] The addition of the TegoRad 2300 suspension was carried out such that a surface-modified semi-gel with the physico-chemical properties indicated in Table 2 was finally obtained.

[0247] Table 2: Physicochemical properties of reactants and products of Ex...

Embodiment 4

[0254] Testing of the paint technical performance of the semi-gels according to the invention in black paint

[0255] As black paint, Duplex D 1326 from the company DuPont (produced by Herberts Austria GmbH) was used. In each case 5.5 g of matting agent were incorporated. 1

[0256] The 60° and 85° reflectometer values are determined according to DIN 67530, ISO 2813 or TM 523-78, and the flat gloss (=85° reflectometer value−60° reflectometer value) is calculated (see Table 3). This flat gloss allows evaluation of the matting effect of the surface at various viewing angles. A lower matte gloss means that the surface appears matte at all viewing angles of the surface.

[0257] Table 3: Black paint

[0258] SiO of the following examples 2

[0259] The data in Table 3 show that, particularly in view of the gloss values at 85°, the matting efficiency of the surface-modified semi-gels according to the invention is comparable to that of precipitation method II tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com