Method for preparing fermentation strains of microbial organic fertilizer

A technology for bio-organic fertilizer and fermentation strains is applied in the field of strain preparation for preparing tobacco straw bio-organic fertilizers by solid-state fermentation, and can solve the problems of no preferred selection of microbial strains, ineffective fermentation and transformation, poor effect, and the like. Yield and the effect of improving internal quality and increasing production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

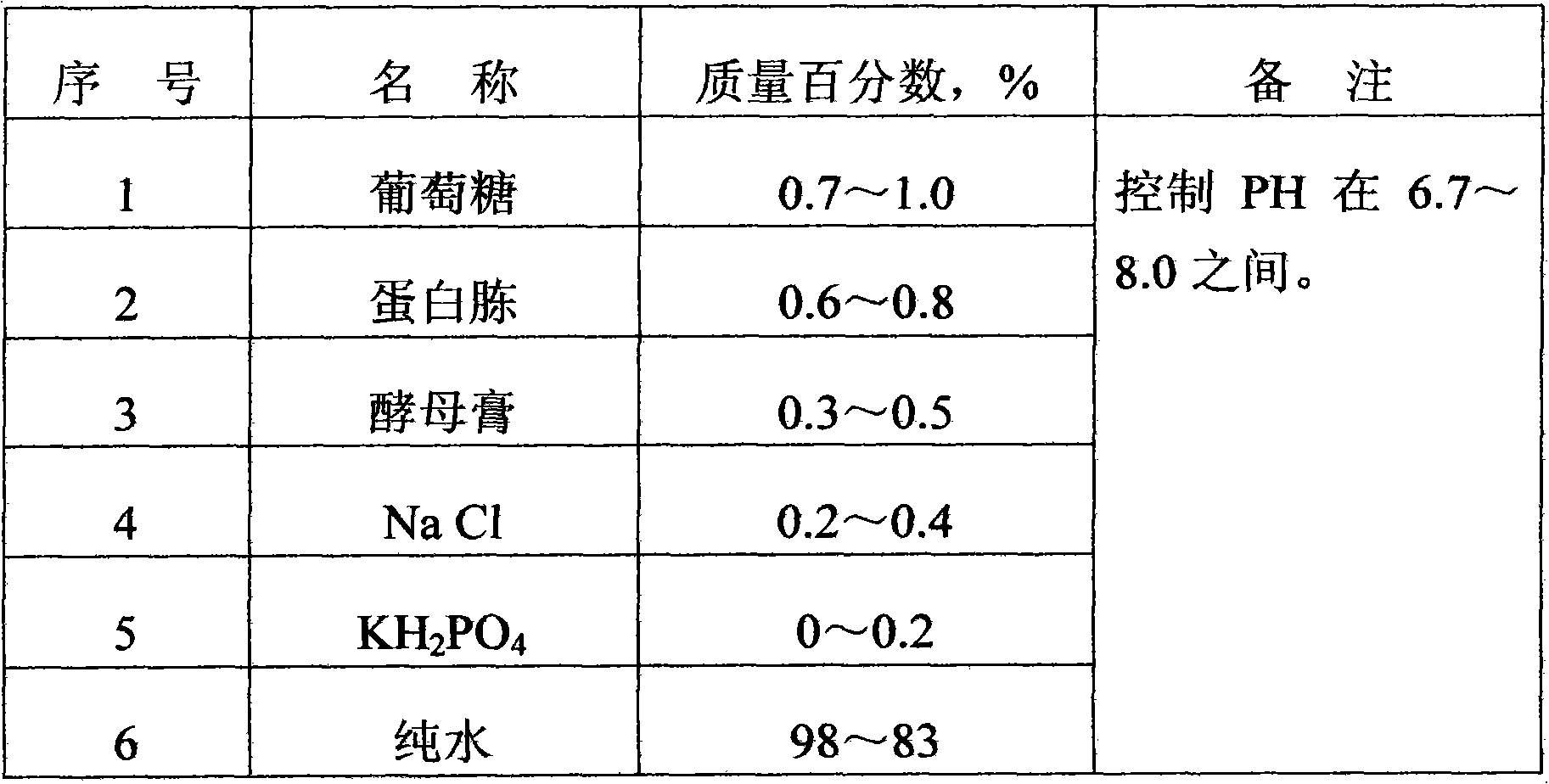

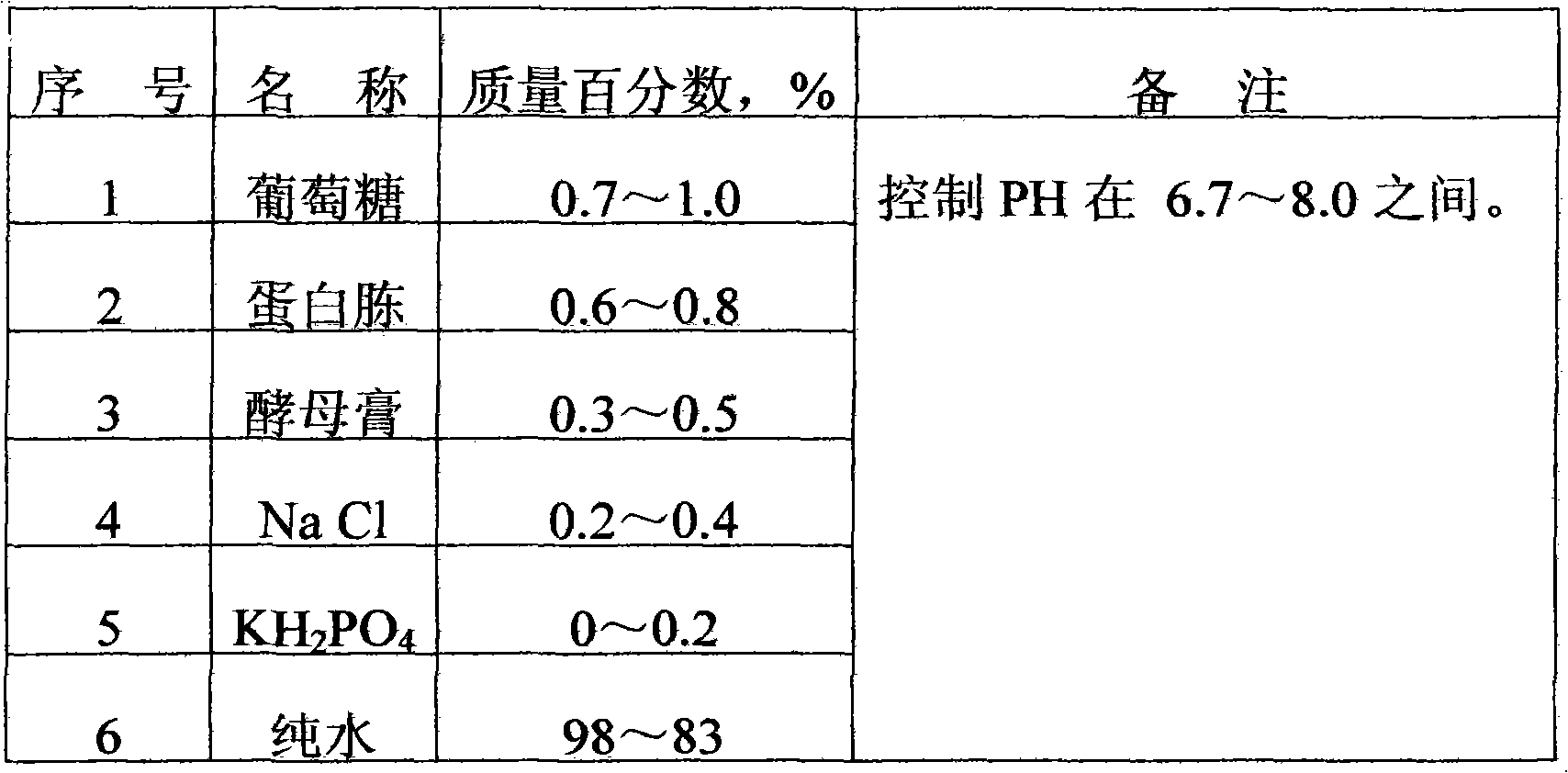

[0032] Strain culture: take the above D 1 Bacteria tube 1 and S 4 1 bacterial tube, respectively inserted in 250ml seed bottles filled with culture medium, the culture medium consists of: 1% glucose, 0.8% peptone, 0.5% yeast extract, 0.4% sodium chloride, and the rest is water. Adjust the pH to 7.8.

[0033] Incubate the 250ml seed bottle for 20 hours at 28±1°C with shaking, and the D 1 Bacteria and S 4 After the bacteria solution is mixed in equal amounts, according to the seed amount of 6% volume ratio, it is then inserted into a 1000ml fermentation bottle; under 28±1°C and shaking conditions, the 1000ml fermentation bottle is cultivated for 24 hours, and the OD600nm value is measured to obtain a fermentation bacterial agent.

Embodiment 2

[0035] Strain culture: take the above D 1 3 bacterial tubes and S 4 1 bacterial tube, respectively inserted into 250ml seed bottles filled with culture medium, the composition of the culture medium is: 0.8% glucose, 0.6% peptone, 0.3% yeast extract, 0.2% sodium chloride, KH 2 PO 4 0.1%, the rest is water. Adjust the pH to 6.7.

[0036]Incubate 250ml seed bottles for 18 hours at 3°C under shaking conditions, and then insert D into 1000ml fermentation bottles at 2% volume ratio. 1 Bacterial solution and 2.5% volume ratio seed quantity were inserted into S 4 Bacterial liquid: Under the condition of 33±℃ and shaking, cultivate 1000ml fermentation bottle for 18 hours, measure the OD600nm value, and obtain the fermentation bacterial agent.

Embodiment 3

[0038] Strain culture: take the above D 1 Bacteria tube 4 and S 4 1 bacterial tube, respectively inserted into 500ml seed bottles filled with culture medium, the composition of the culture medium is: 0.85% glucose, 0.7% peptone, 0.4% yeast extract, 0.3% sodium chloride, KH 2 PO 4 0.2%, the rest is water. Adjust the pH to 7.5.

[0039] Incubate 500ml seed bottles for 16 hours at 35°C under shaking conditions, and D 1 Bacteria and S 4 After the bacterial liquid is mixed, according to the 5% volume ratio of the seed amount, it is then connected to a 100L automatic fermenter for expanded cultivation. The pressure of the fermenter is controlled to 0.5mpa, the tank temperature is 2°C, the ventilation rate is 0.4 (v / v / min), and the stirring speed is 200rpm , cultured for 18 hours to obtain a fermentation broth.

[0040] The above-mentioned fermentation culture was concentrated 4 times by membrane filtration, and the liquid bacterial agent was detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com