Annealing device and annealing method for improving impedance effect of soft magnetic material

A technology of soft magnetic materials and annealing devices, applied in the field of magnetic sensors, can solve the problems of poor promotion and expensive equipment, and achieve the effects of low cost, increased magnetic impedance ratio, and reduced hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

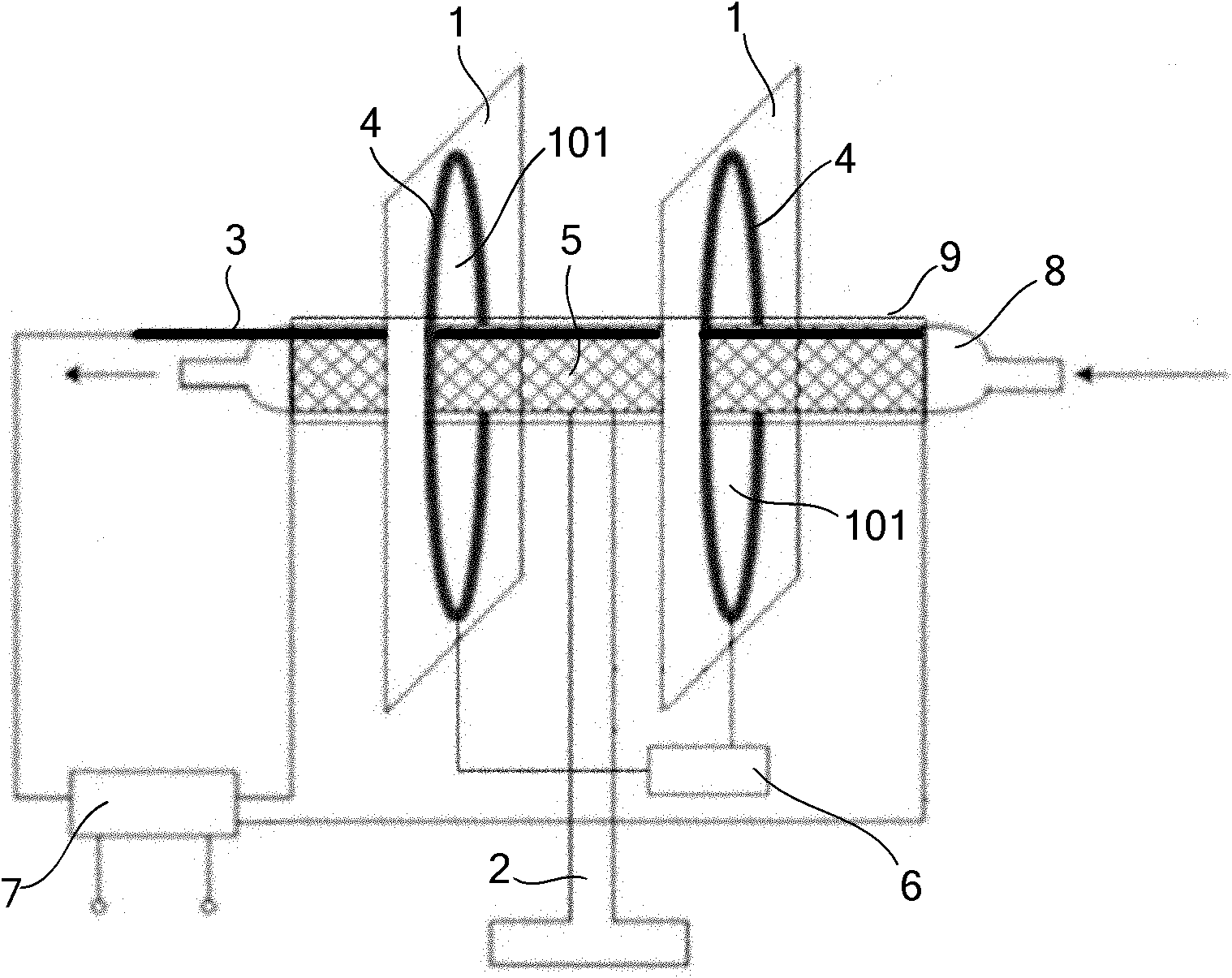

[0064] Example: CoFeSiB ribbons are annealed using the annealing device of the present invention.

[0065] Fix the CoFeSiB tape on the ceramic plate, put it into the measured uniform temperature zone in the quartz tube 8, cover the quartz cap 803 at the front end of the quartz tube 8, and pass argon gas through the front end of the quartz tube 8, and use the temperature controller 7 Heating the heating belt 5 and controlling the temperature controller 7 at 450°, and then applying a DC magnetic field in the axial direction of the quartz tube 8 through the Helmertz coil 4 to control the direction of the easy magnetic axis of the CoFeSiB belt and change the direction of the CoFeSiB belt The anisotropy of the CoFeSiB strip can be achieved to change the magnetoresistance effect of the CoFeSiB strip. After the CoFeSiB strip is heated for a certain period of time, it is naturally cooled to room temperature and taken out.

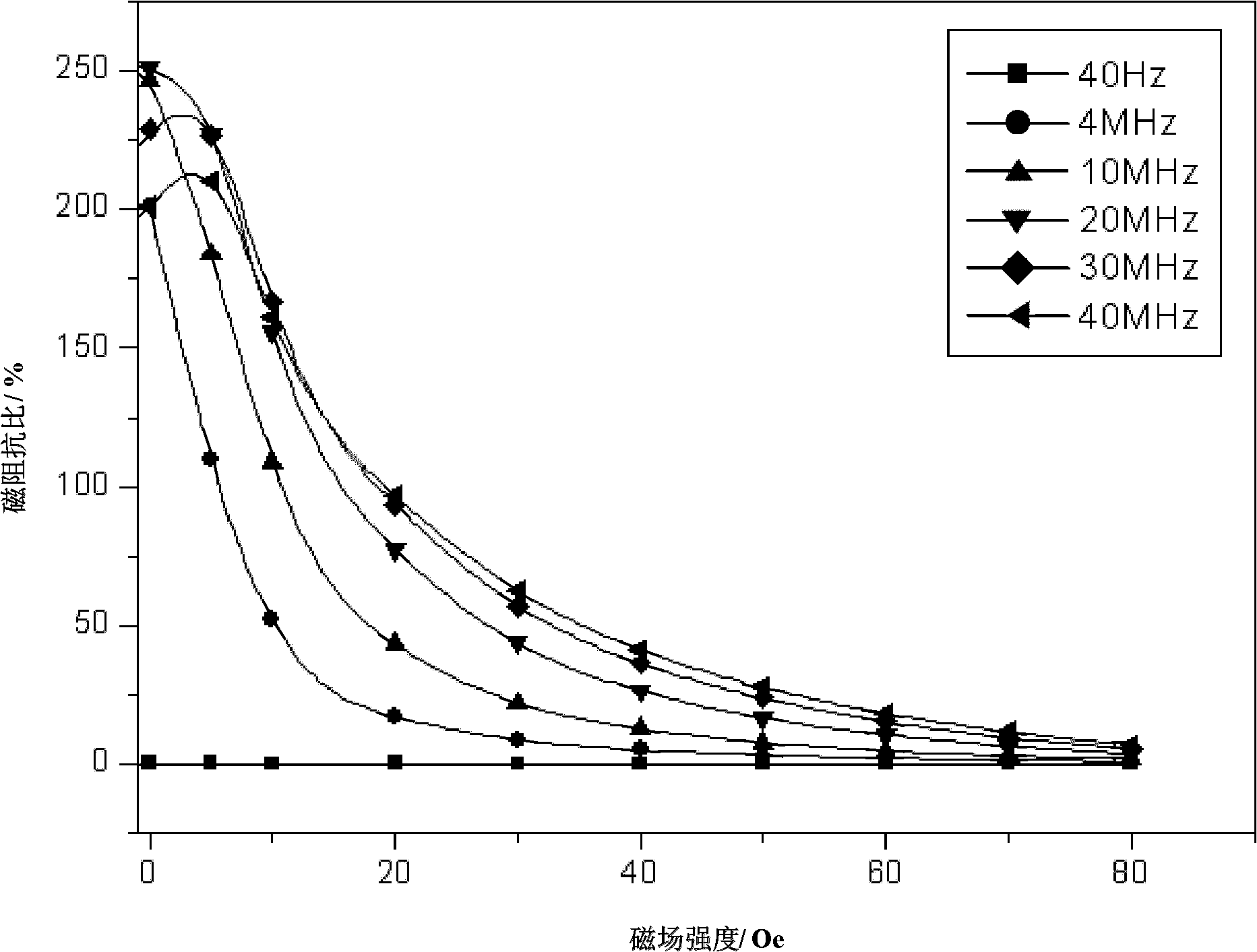

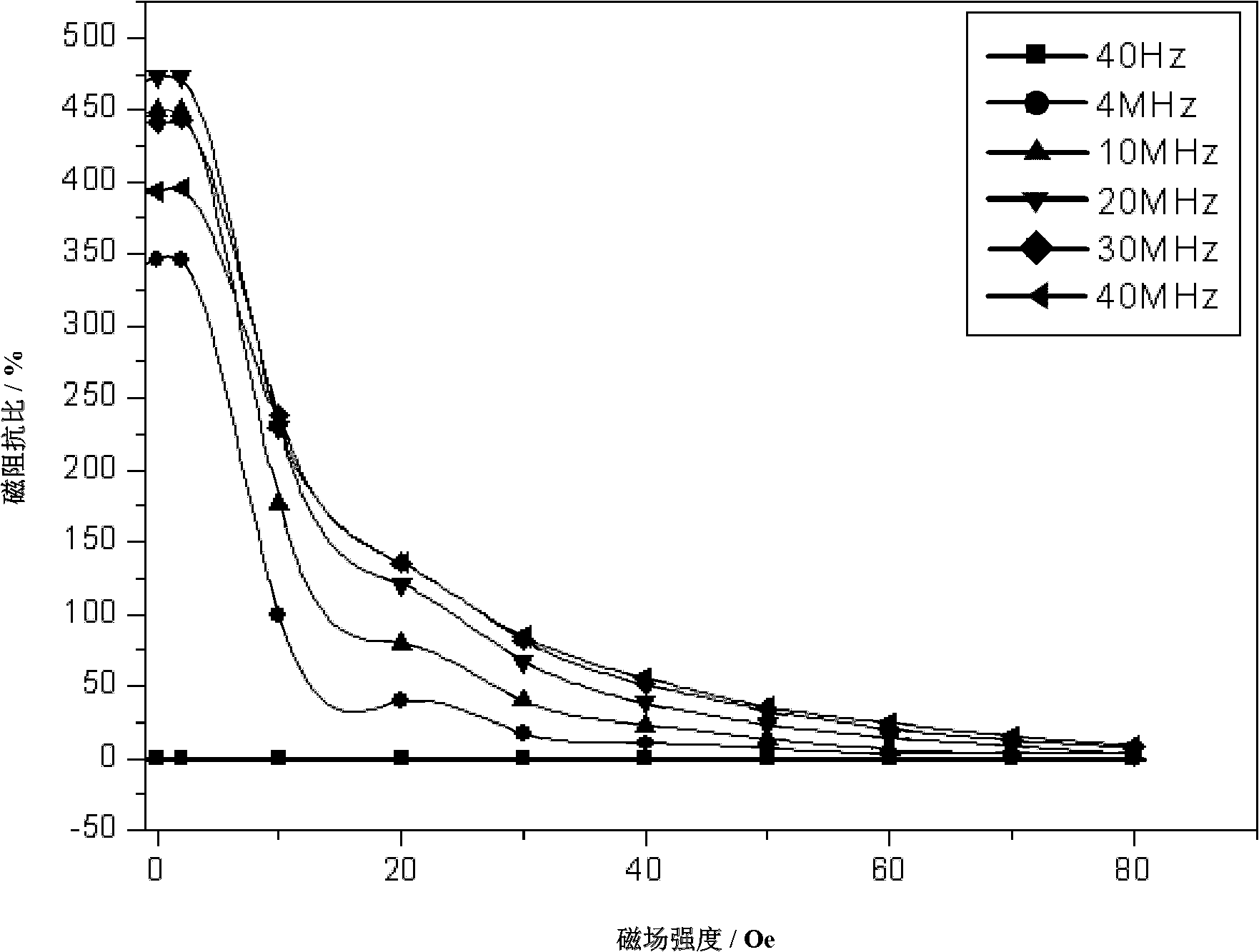

[0066] Such as Figure 6a and Figure 6b Shown are the impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com