Variable damping absorber

A shock absorber and damping technology, applied in shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve problems such as short life, difficult manufacturing, and easy precipitation of magnetorheological fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

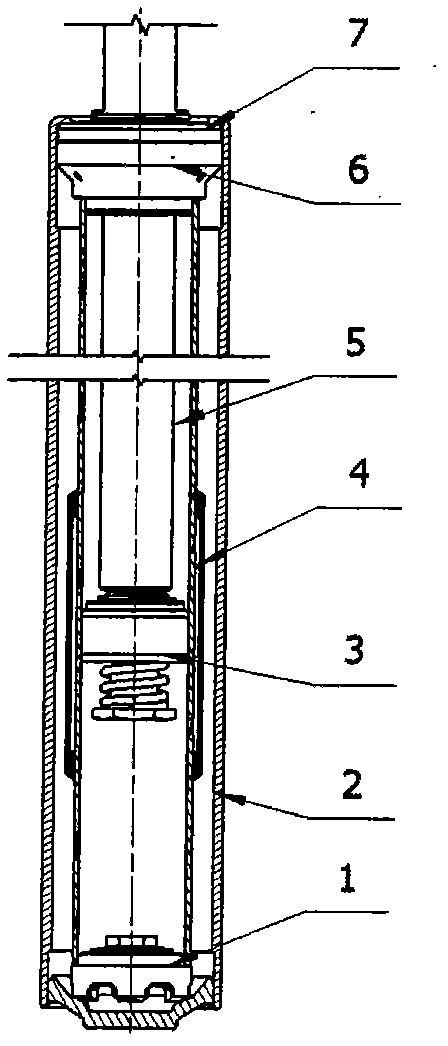

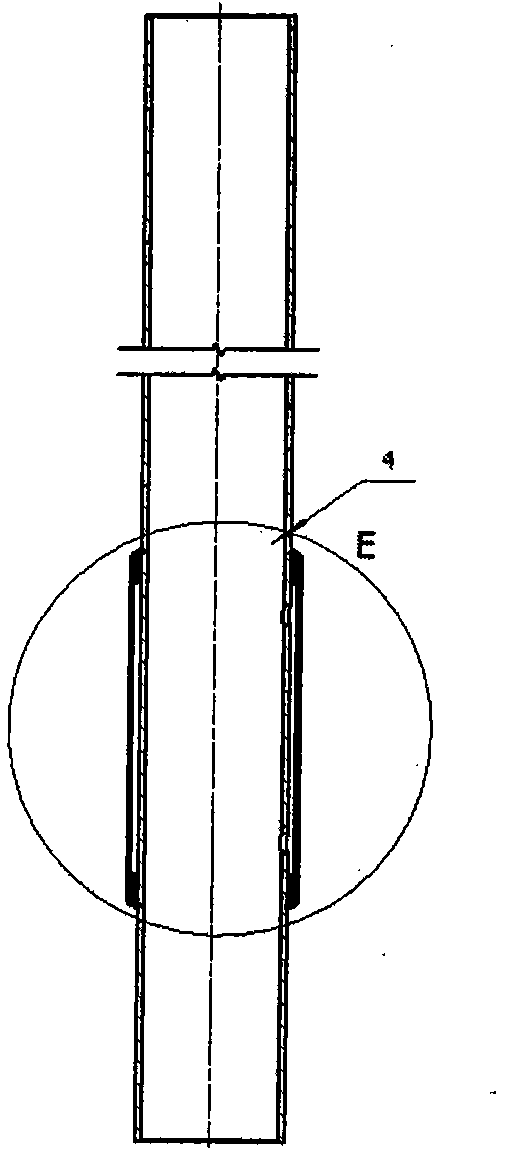

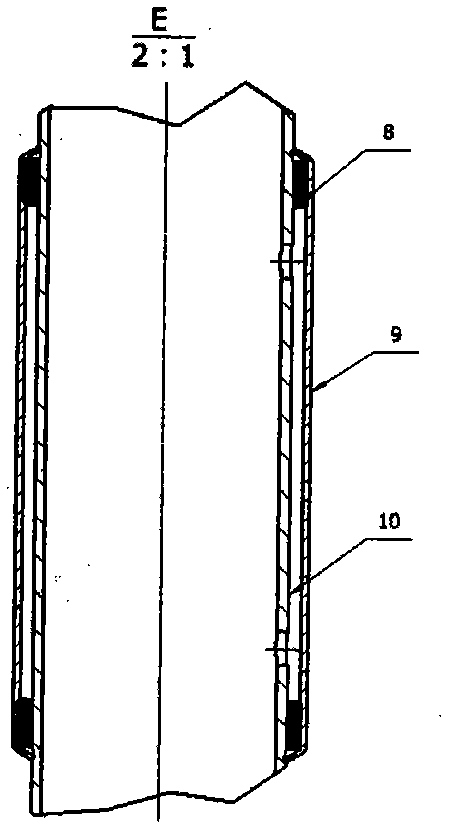

[0018] The variable damping shock absorber involved in the present invention achieves the purpose of changing the damping force of the shock absorber by changing the effective area of the orifice through which the oil liquid of the shock absorber flows. The variable damping shock absorber such as figure 1 Shown is based on the existing double-tube hydraulic shock absorber, drill 1 to 4 pairs of round holes with different center distances on the working cylinder wall along the direction of its generatrix. The balance position of the holes is the vibration reduction under the rated load of the vehicle. The equilibrium position of the piston of the device. Such as figure 2 and image 3 As shown, the size of the hole drilled on the working cylinder is Φ1.0~3.0mm, the hole center distance is 25~60mm, and the hole is separated from the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com