Enhancing method of oxygen mass transfer efficiency of microbial fuel cell cathode and corresponding cell

A fuel cell cathode and mass transfer efficiency technology, which is applied in the direction of biochemical fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of insignificant increase in power production capacity, low concentration of dissolved oxygen, and anaerobic conditions caused by dissolved oxygen damage to the anode, etc. problems, to achieve the effect of improving disturbance state, increasing reaction efficiency, and promoting mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

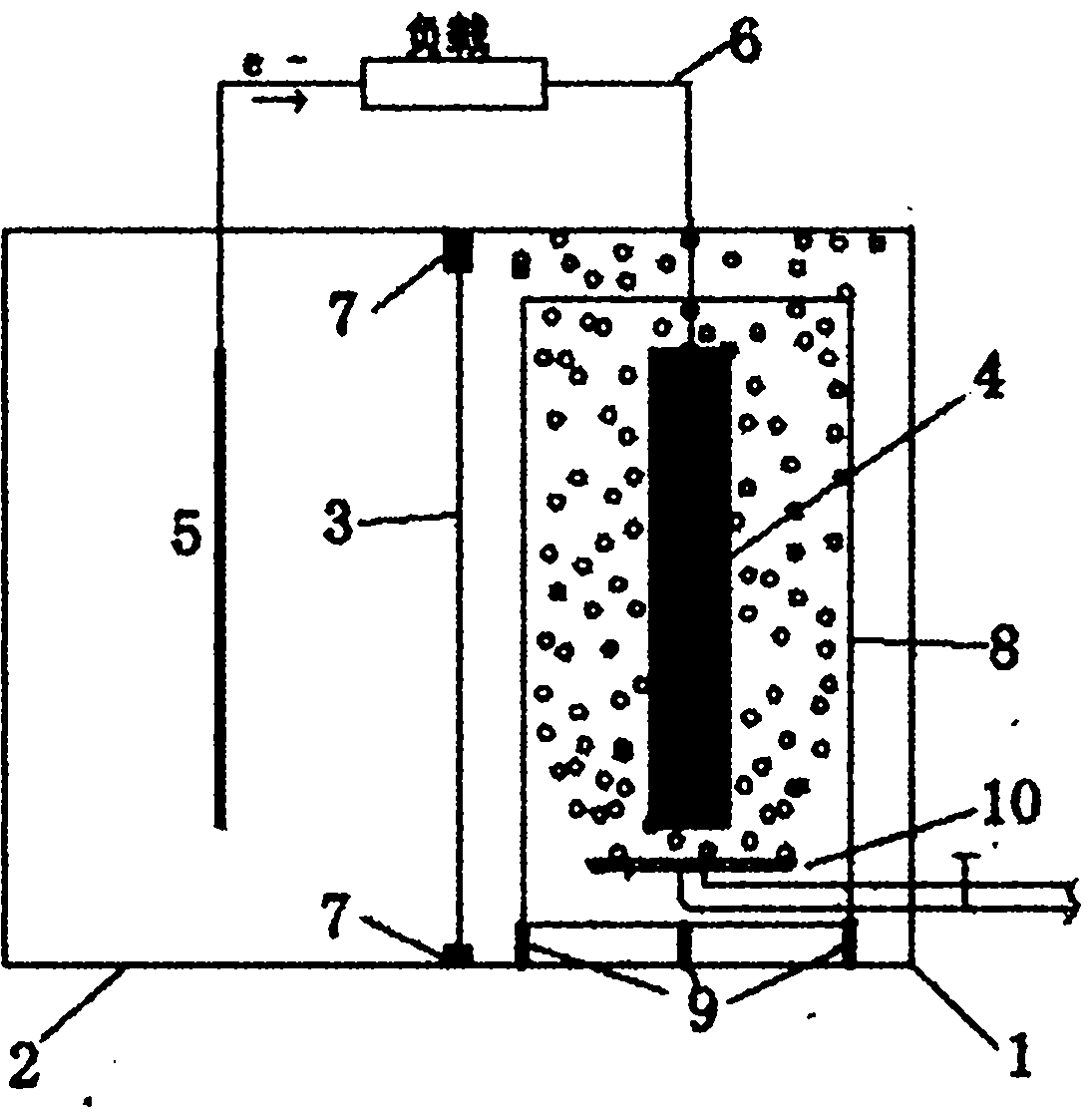

[0035] Such as figure 1 As shown, the microbial fuel cell given in this embodiment is composed of a cathode chamber 1 , an anode chamber 2 , a proton exchange membrane 3 , a cathode electrode 4 , an anode electrode 5 , a flow guiding mechanism 8 and an aeration mechanism 10 .

[0036]The cathode electrode 4 is in the form of a sheet, and the anode electrode 5 is in the shape of a column, which are suspended in the cathode chamber 1 and the anode chamber 2 respectively, and are respectively connected to the load through wires 6 . The proton exchange membrane 3 is located between the cathode chamber 1 and the anode chamber 2 through a fixed splint 7 and is parallel to the sheet cathode electrode 4 . The guide mechanism 8 is a straight guide tube in this embodiment, and is supported by a foot 9 extending from the bottom edge above the aeration mechanism 10 in the cathode chamber 1, and the volume surrounded by it accounts for 10% of the total volume of the cathode chamber 1. ~70...

Embodiment 2

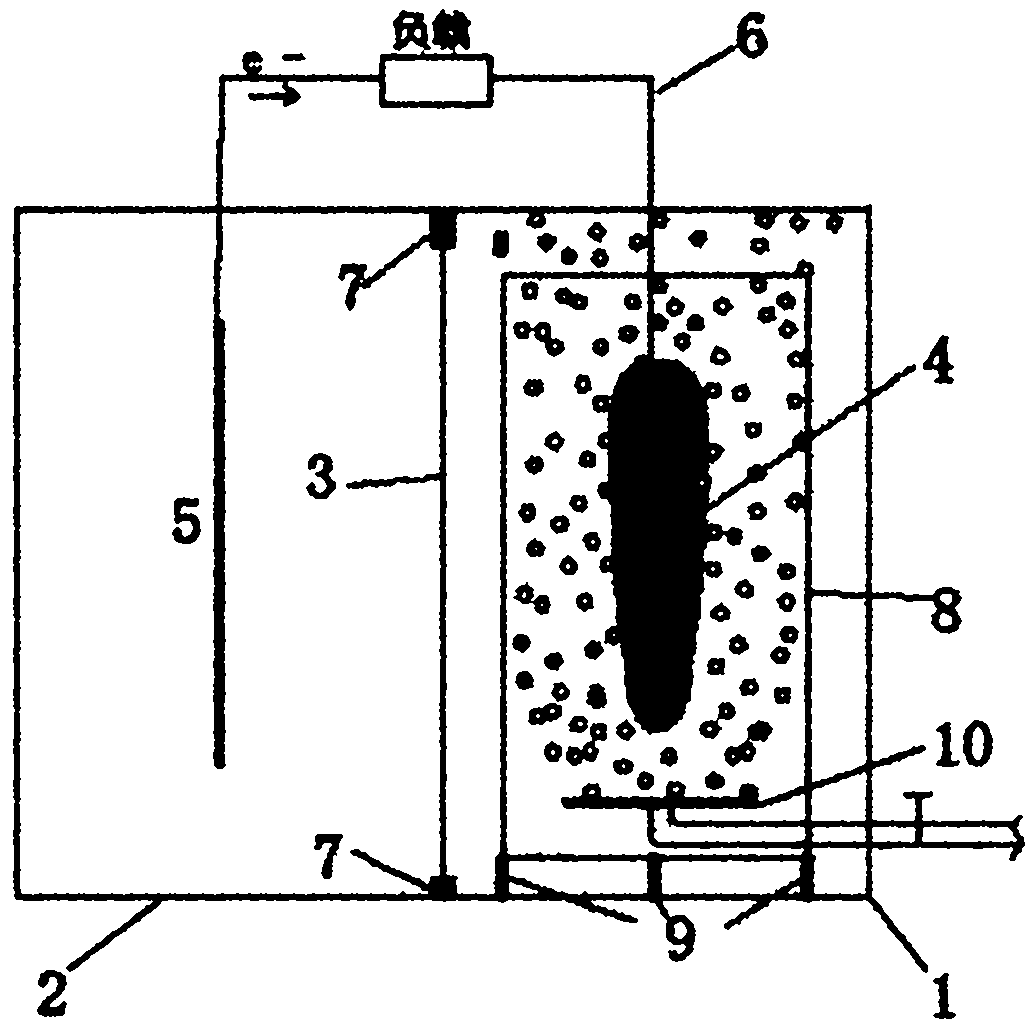

[0038] Such as figure 2 As shown, the microbial fuel cell given in this embodiment is also composed of a cathode chamber 1 , an anode chamber 2 , a proton exchange membrane 3 , a cathode electrode 4 , an anode electrode 5 , a flow guiding mechanism 8 and an aeration mechanism 10 .

[0039] This embodiment is the same as the embodiment 1 except that the shape of the cathode electrode 4 is designed to be elastic, so the description is omitted here. The shape of the cathode electrode 4 is designed to be elastic. One is to make the air bubbles rising along the electrode wall have a flushing effect on the electrode, which can clean the combined water layer or biofilm attached to the electrode, which is conducive to the mass transfer of oxygen to the electrode surface; The second is to make the bubbles easily gather in the turbulent wake area formed on the upper end of the electrode, and increase the residence time of the protons here, which is beneficial to speed up the reaction s...

Embodiment 3

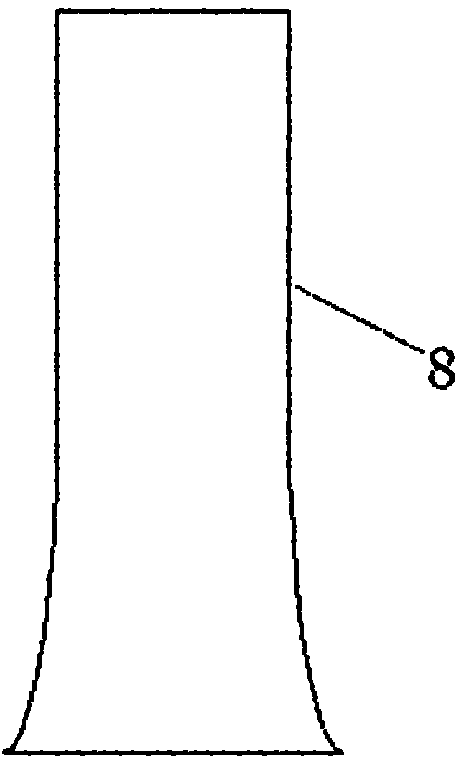

[0041] Such as figure 1 As shown, the microbial fuel cell given in this embodiment is also composed of a cathode chamber 1 , an anode chamber 2 , a proton exchange membrane 3 , a cathode electrode 4 , an anode electrode 5 , a flow guiding mechanism 8 and an aeration mechanism 10 . What is different from Embodiment 1 is that the guide tube of the guide mechanism 8 is a straight cylindrical shape with a trumpet-like lower port, see image 3 , the trumpet-shaped guide tube can change the water flow line, reduce the resistance during liquid circulation, increase the mass transfer rate of protons to the electrode, and make it easier to react with the oxidant and the electrons that are conducted to the cathode through an external circuit, thereby improving the cathode. reaction efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com