Plasma processing apparatus

A processing device, plasma technology, applied in the direction of plasma, gaseous chemical plating, coating, etc., can solve the problems of mutual interference, unstable discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

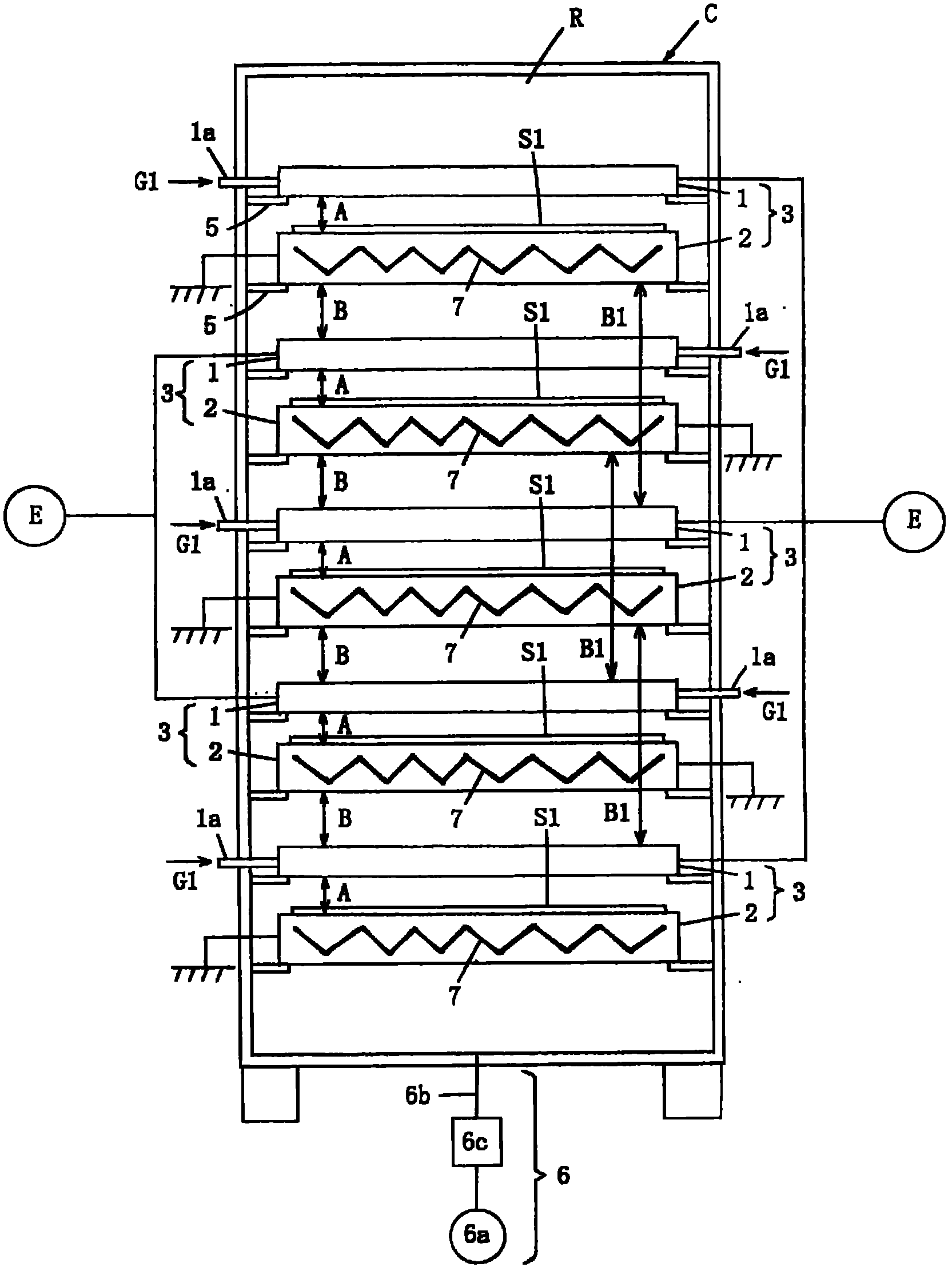

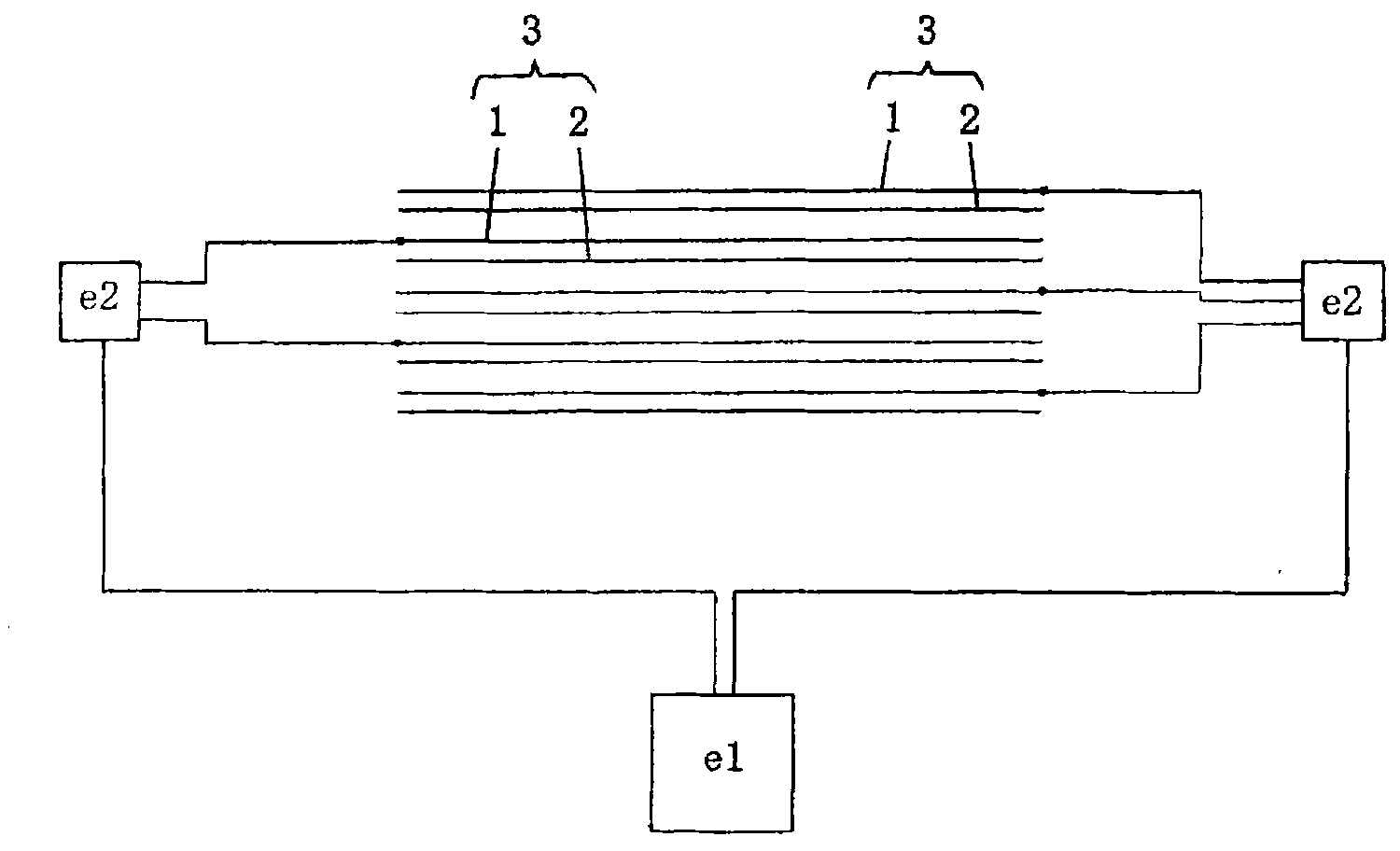

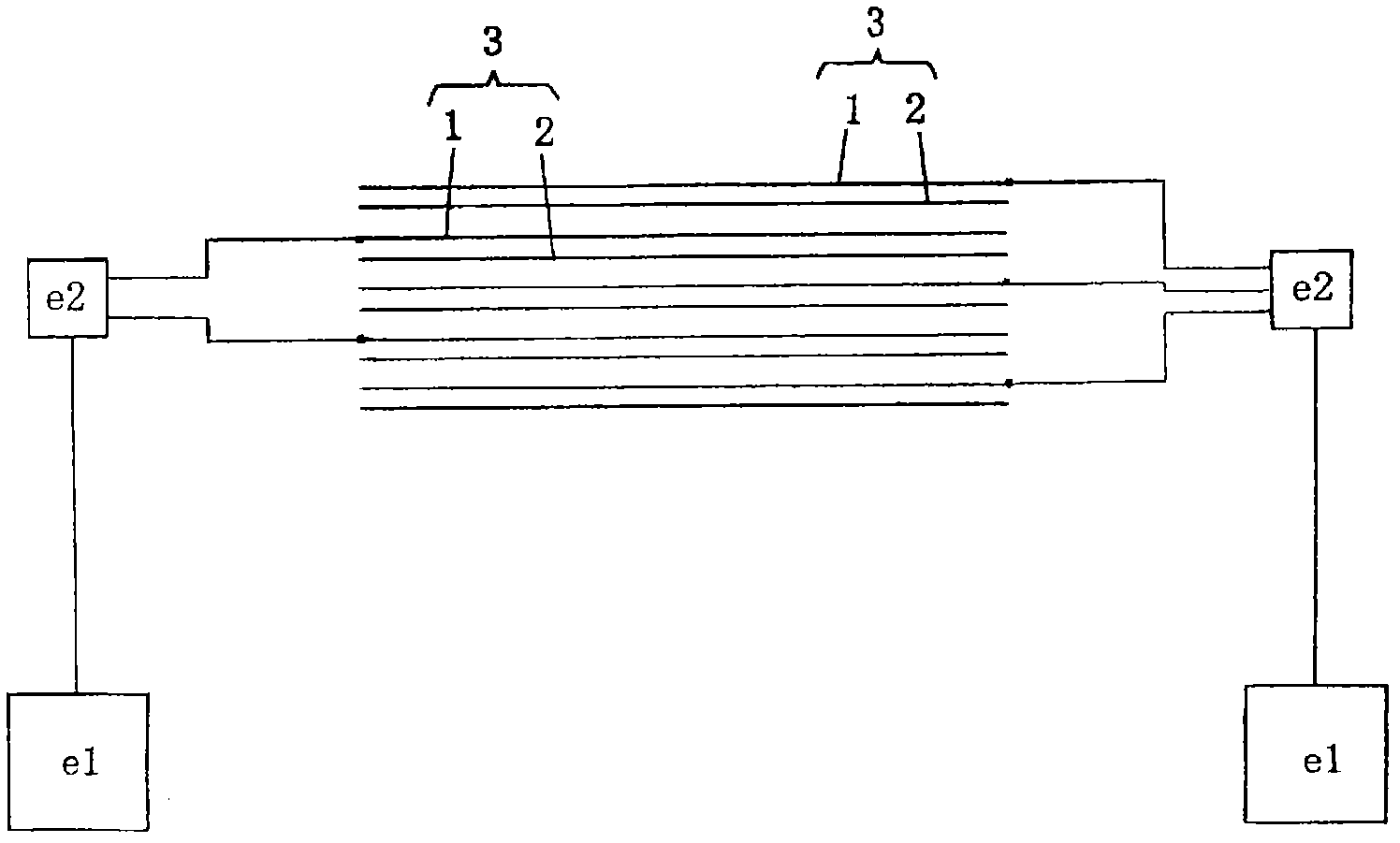

[0077] figure 1 It is a schematic configuration diagram showing Embodiment 1 of the plasma processing apparatus of the present invention. figure 2 It is an explanatory diagram showing the first power supply connection form of Embodiment 1, image 3 It is an explanatory diagram showing the second power supply connection form of the first embodiment.

[0078] The plasma processing apparatus of Embodiment 1 is a vertical side-by-side type plasma processing apparatus for coating a desired film on the surface of the substrate S1 as an object to be processed, and includes: a reaction chamber R, an introduction to the reaction chamber R The gas introduction part 1a for the reaction gas G1, the exhaust part 6 for discharging the reaction gas G1 from the reaction chamber R, and the first electrode 1 and the second electrode 1 which are arranged in a facing state in the reaction chamber R and perform plasma discharge in the reaction gas G1 Three or more sets of discharge parts 3 com...

Embodiment approach 2

[0110] Figure 5 It is a schematic configuration diagram showing Embodiment 2 of the plasma processing apparatus of the present invention. In addition, in Figure 5 in, right with Figure 1 to Figure 4 The same reference numerals are assigned to the same constituent elements as those shown.

[0111] The plasma processing apparatus of Embodiment 2 is also a plasma processing apparatus for coating, but differs from Embodiment 1 (vertical side-by-side type) mainly in that it is a left-right side-by-side type. That is, in the plasma processing apparatus of Embodiment 2, the figure 1 The plasma processing apparatus having the structure of Embodiment 1 described in .

[0112] exist Figure 5 , omitting the illustration shows the figure 1 The chamber C, the support part 5, and the exhaust part 6 are depicted in , but the plasma processing apparatus according to Embodiment 2 also includes these. Among them, in the case of Embodiment 2, the support part supports the negative e...

Embodiment approach 3

[0118] Figure 6 It is a schematic configuration diagram showing Embodiment 3 of the plasma processing apparatus of the present invention. In addition, in Figure 6 in, right with figure 1 Structural elements that are the same as those shown are assigned the same reference numerals.

[0119] The plasma processing apparatus of Embodiment 3 is a vertically arranged plasma processing apparatus for etching. Like Embodiment 1, it has a plurality of sets of discharge parts 13 composed of negative electrodes 11 and positive electrodes 12, and has a chamber not shown in the figure. , support portion, and exhaust portion.

[0120] The main difference between the third embodiment and the first embodiment is that the negative electrode 11 and the positive electrode 12 are arranged upside down in each discharge part 13, the substrate S2 is provided on the negative electrode 11 connected to the power supply part E, and the grounded positive electrode The electrode 2 is arranged above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com