Process for calcining small-granularity dolomite of 20-40 millimeters

A calcination process and small particle size technology, which is applied in the field of dolomite calcination, can solve the problems that affect the smooth production, low calcination quality and efficiency, and unstable process, so as to prevent nodules, eliminate flames from the top of the furnace, and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

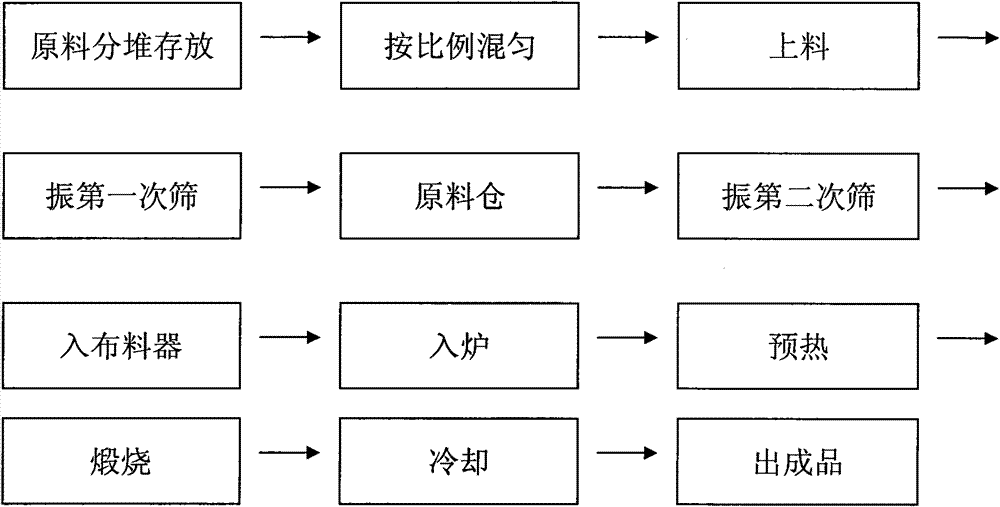

[0020] Present embodiment is that the dolomite child of 40 millimeters-80 millimeters particle size and the small particle size dolomite child of 20 millimeters-40 millimeters are mixed as example in the ratio of 2:1.

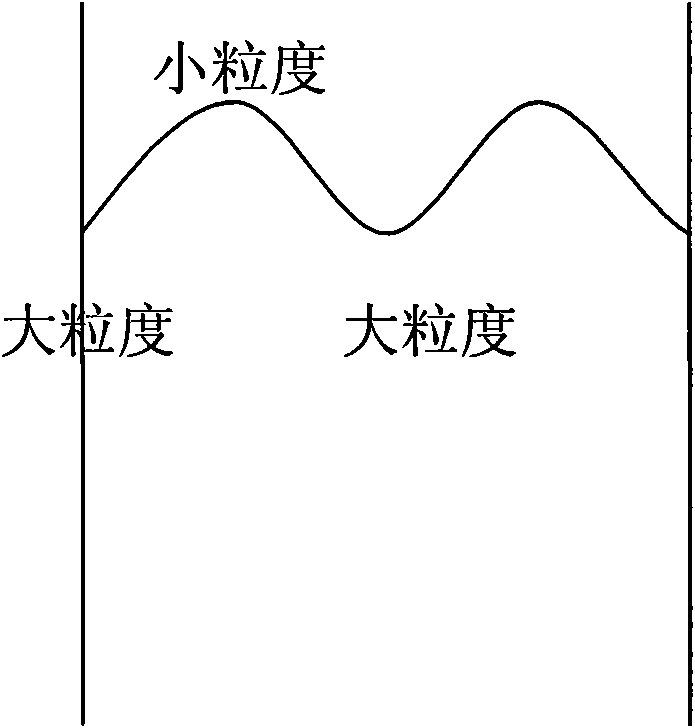

[0021] (1) mix 40mm-80mm particle size dolomite and 20mm-40mm small particle size dolomite in a ratio of 2:1, and deliver to furnace top charging bell through three vibrating sieves, the diameter of vibrating sieve is 8 mm, The dolomite stones of different particle sizes from top to bottom in the vertical direction in the furnace are stacked in the following ways: 40mm-80mm particle size, 20mm-40mm small particle size, 40mm-80mm particle size, The distance between the material surface in the furnace and the furnace mouth is controlled to be 500 mm;

[0022] (2) Preheating, the temperature of the preheating zone is controlled at 300°C;

[0023] (3) Calcining, the temperature of the calcining zone is controlled to be 1050°C, and the proportioning ratio of gas an...

Embodiment 2

[0027] In this embodiment, the dolomite with a particle size of 40mm-80mm and the dolomite with a small particle size of 20mm-40mm are mixed in a ratio of 4:1 as an example. The diameter of the furnace is 10 mm, and the distance between the material surface in the furnace and the furnace mouth is controlled to be 600 mm, the temperature of the preheating zone is controlled to be 300 °C, the temperature of the calcining zone is controlled to be 1000 °C, the temperature of the cooling zone is controlled to be 200 °C, and the ash discharge temperature is controlled to be 100 °C. ℃, the furnace top temperature is controlled at 120 ℃, the ratio of gas and air volume during calcination is controlled at 1:1.1, and the ash output per time is 5 tons. All the other are the same as in Example 1.

Embodiment 3

[0029] In this embodiment, the dolomite with a particle size of 40mm-80mm and the dolomite with a small particle size of 20mm-40mm are mixed in a ratio of 3:1 as an example, and are sent to the furnace top material bell through three vibrating screens, and the vibrating screen The diameter of the furnace is 11 mm, and the distance between the material surface in the furnace and the furnace mouth is controlled at 570 mm, the temperature of the preheating zone is controlled at 420 °C, the temperature of the calcining zone is controlled at 1030 °C, the temperature of the cooling zone is controlled at 270 °C, and the ash discharge temperature is controlled at 95 °C. ℃, the furnace top temperature is controlled at 130 ℃, the ratio of gas and air volume during calcination is controlled at 1:1.2, and the ash output per time is 5 tons. All the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com