Sealant composition for liquid crystal display device

A technology for liquid crystal displays and sealants, applied in instruments, chemical instruments and methods, modified epoxy resin adhesives, etc., can solve problems such as liquid crystal contamination, and achieve low contamination levels, excellent adhesion strength, and excellent storage stability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

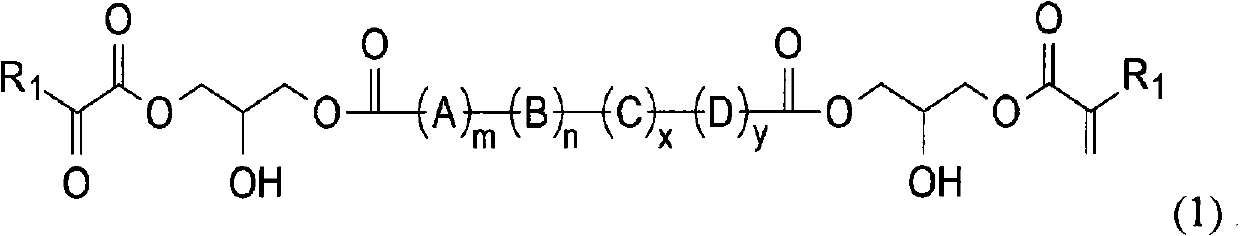

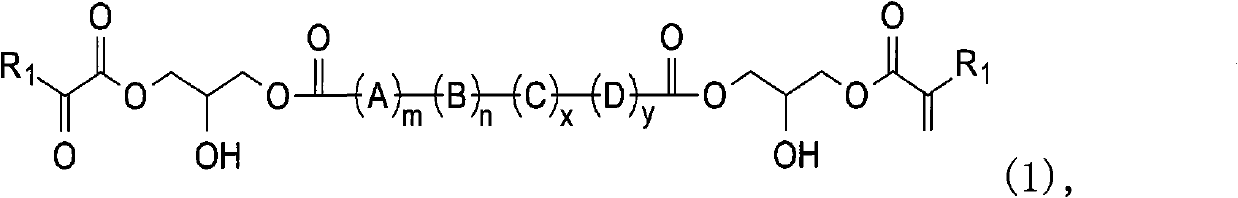

[0043] 71 g of a modified epoxy resin containing 1 g of a (meth)acrylate compound represented by Chemical Formula 1, 2 g of a photoinitiator, 10 g of SP-15 (manufactured by Osaka kasel) and 10 g of Aerosil200 (manufactured by Degu) as an inorganic filler were mixed, 3 g Silane coupling agent, 2g of malonate dihydrazide (MDH manufactured by ALDRICH) and 2g of Amicure UR (manufactured by Airproduct) as a thermosetting agent, fully grind the mixed composition using a three-roll mill, And the milled composition was vacuum deformed using a spin-rotation deformer, and a sealant composition was obtained.

Embodiment 2

[0045] 71 g of a modified epoxy resin containing 3 g of a (meth)acrylate compound represented by Chemical Formula 1, 2 g of a photoinitiator, 10 g of SP-15 (manufactured by Osaka kasel) and 10 g of Aerosil200 (manufactured by Degu) as an inorganic filler were mixed, 3 g Silane coupling agent, 2g of malonate dihydrazide (MDH manufactured by ALDRICH) and 2g of Amicure UR (manufactured by Airproduct) as a thermosetting agent, fully grind the mixed composition using a three-roll mill, And the milled composition was vacuum deformed using a spin-rotation deformer, and a sealant composition was obtained.

Embodiment 3

[0047] 71 g of a modified epoxy resin containing 10 g of a (meth)acrylate compound represented by Chemical Formula 1, 2 g of a photoinitiator, 10 g of SP-15 (manufactured by Osaka kasel) and 10 g of Aerosil200 (manufactured by Degu) as an inorganic filler were mixed, 3 g Silane coupling agent, 2g of malonate dihydrazide (MDH manufactured by ALDRICH) and 2g of Amicure UR (manufactured by Airproduct) as a thermosetting agent, fully grind the mixed composition using a three-roll mill, And the milled composition was vacuum deformed using a spin-rotation deformer, and a sealant composition was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com