Hydrophobic amorphous alloy coating and preparation method thereof

A technology of amorphous alloys and iron-based amorphous alloys, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of non-durable hydrophobicity, poor matrix bonding force, and low mechanical strength, and achieve Low cost, excellent corrosion resistance, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] When preparing:

[0033] (1) First, the master alloy is prepared by vacuum induction melting according to the above-mentioned required components, and then the master alloy is put into the atomization furnace, and the amorphous alloy powder is prepared by the gas atomization technology.

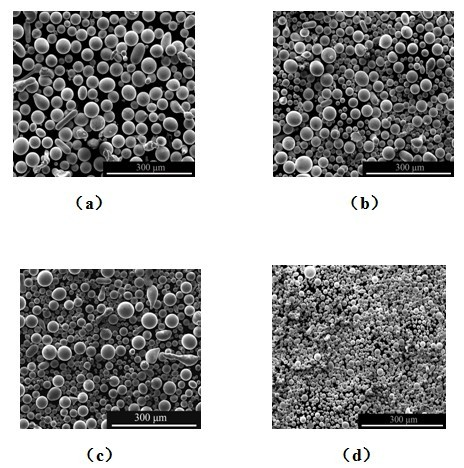

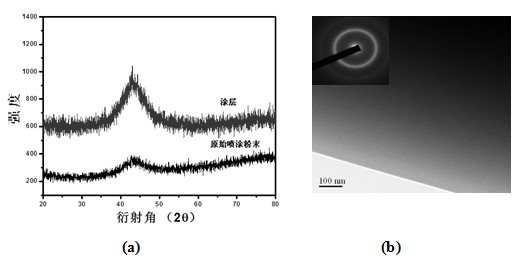

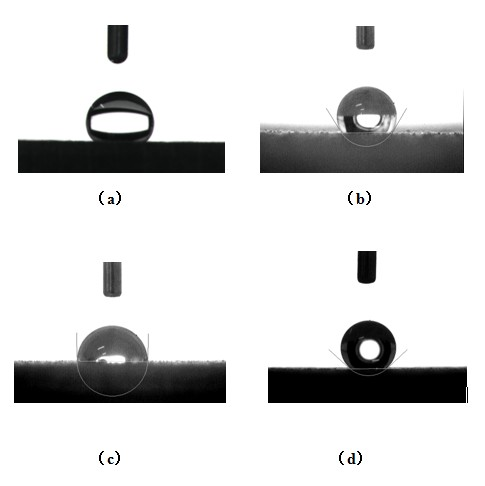

[0034] (2) Afterwards, the amorphous alloy powder with a particle size distribution of 45-55 μm is selected, and the powder particle morphology is as follows figure 1 a, Most of the powders are nearly spherical and have good fluidity, which is suitable as a precursor powder for thermal spraying. X-ray diffraction patterns of amorphous alloy powder and its coating figure 2 As shown in a, it can be seen from the figure that both the powder and the prepared coating are amorphous. We further examined the structure of the iron-based amorphous alloy coating with a transmission electron microscope (TEM), such as figure 2 As shown in b, the bright field image of the coated sample has no o...

Embodiment 2

[0044] The difference from Example 1 is:

[0045] The particle size of the amorphous powder used in this example ranges from 33 to 45 μm; the specific spraying parameters of the supersonic flame spraying kerosene flow rate is 16L / h; the obtained coating is completely amorphous, and the surface morphology of the coating is mostly unmelted or semi-molten particles. Its contact angle is image 3 As shown in c, the static contact angle of the amorphous alloy coating in this example is 122°, indicating that the coating has good hydrophobic properties. The corrosion resistance of the coating is better than that of 316 stainless steel.

Embodiment 3

[0047] The difference from Example 1 is:

[0048] The particle size of the amorphous powder used in this example ranges from 20 to 33 μm; the specific spraying parameters of supersonic flame spraying are kerosene flow rate of 14L / h; the obtained coating is completely amorphous, and its contact angle is as follows: image 3 As shown in b, the static contact angle of the amorphous alloy coating in this example is 92°, indicating that the coating has good hydrophobic properties. The corrosion resistance of the coating is better than that of 316 stainless steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com