Thermal storage water heating system and heating mode

A technology of heating system and hot water storage tank, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of high electricity price, achieve the effect of large income, small investment and lower discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

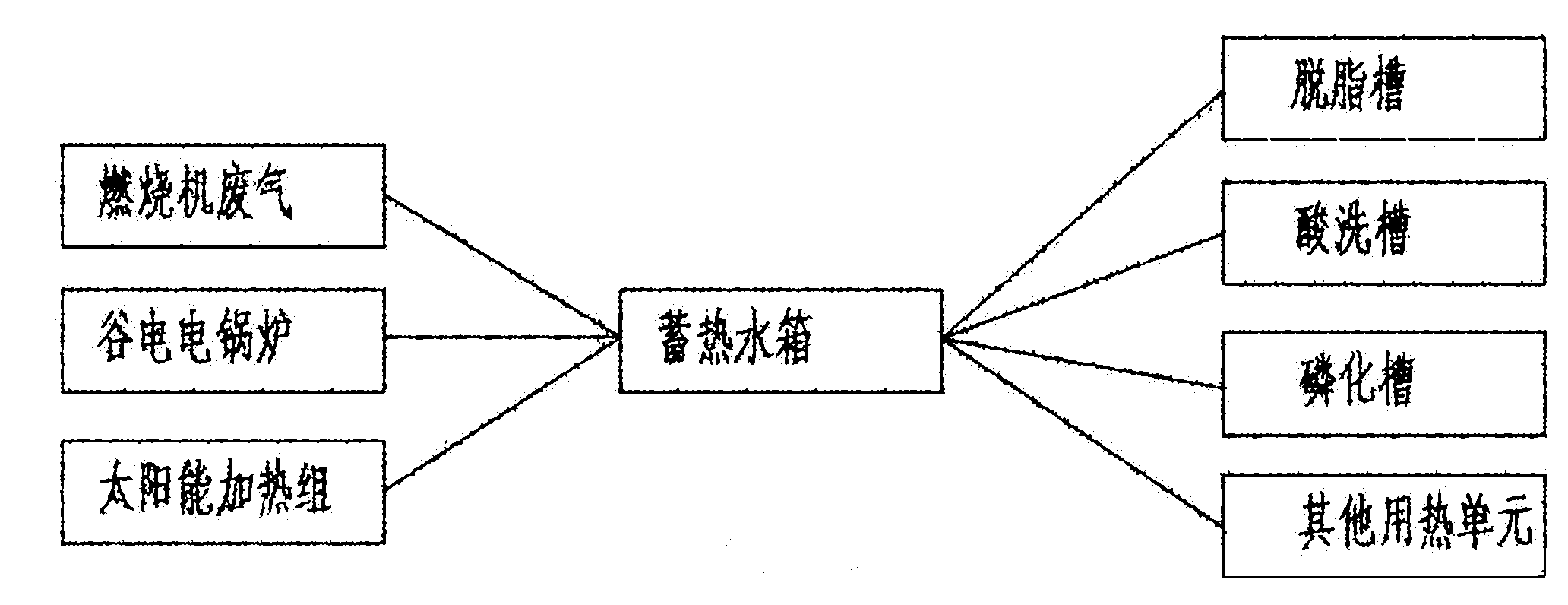

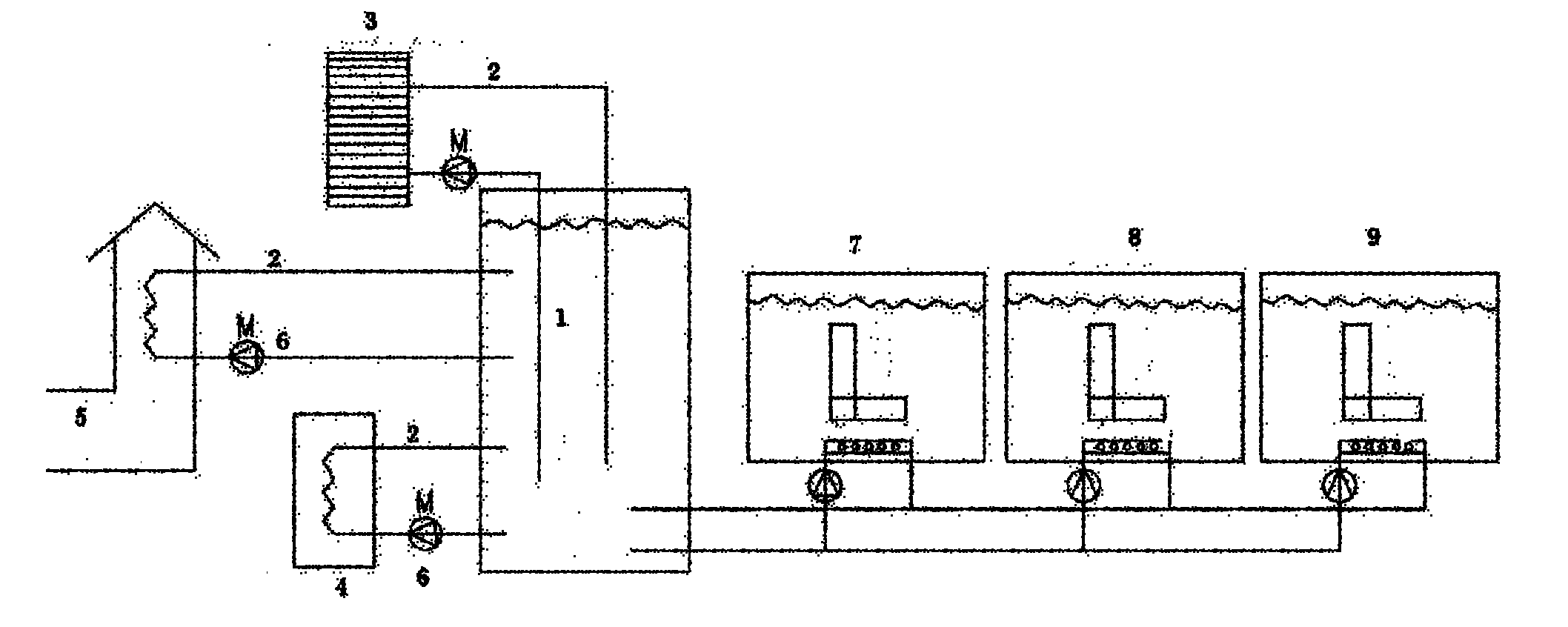

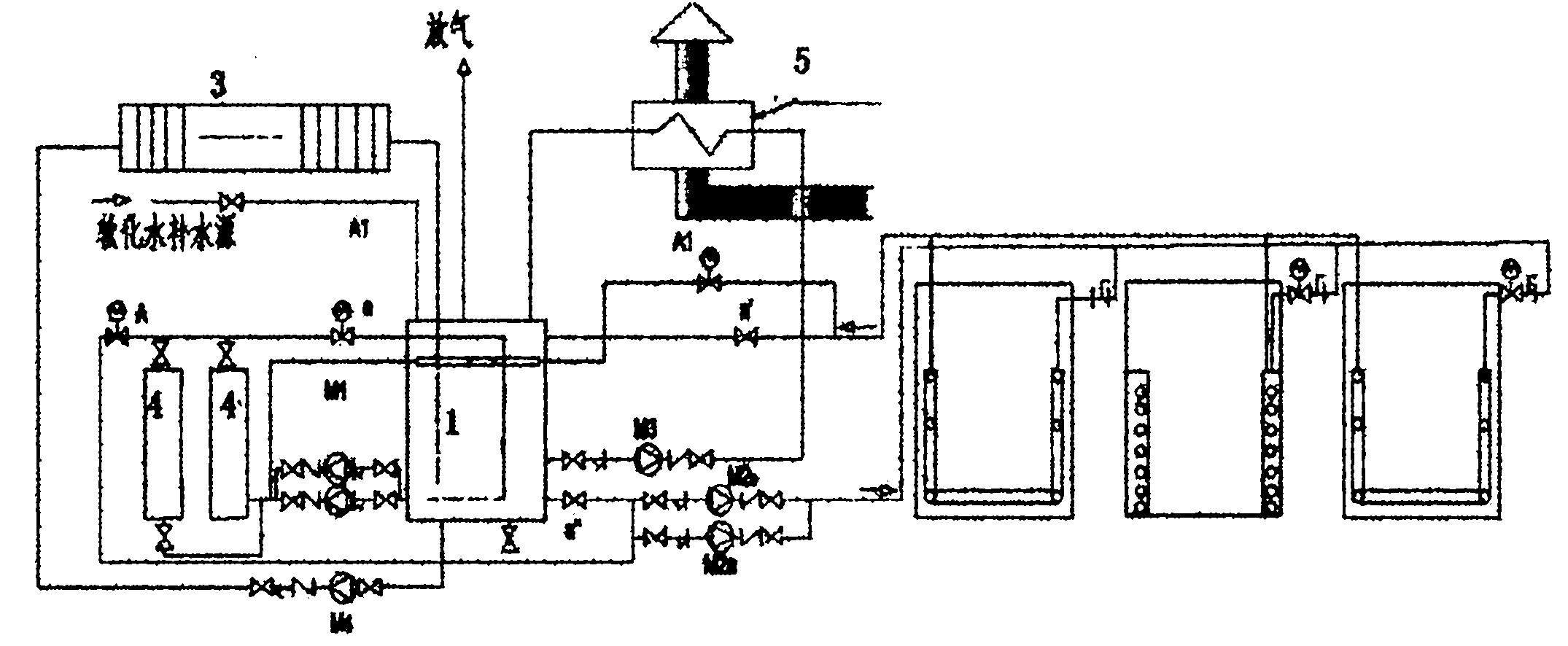

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and the example of the heating pretreatment process of each solution tank in the passenger car small parts pretreatment workshop.

[0036] A hot water storage heating system, including a hot water storage tank 1, the hot water storage tank 1 is discharged from the vacuum tube solar water heater 3, the valley electric boiler 4, and the waste gas waste heat flue gas heat exchanger of the drying room through three sets of heating circulation pipes 2 The pipes 5 are connected together, and each group of heating circulation pipes 2 is provided with a circulation pump 6, and the circulation pump 6 is connected with a controller for controlling its operation.

[0037] The controller is connected with a temperature sensor, and the temperature sensor is arranged in each group of circulation pipes.

[0038] The controller includes a vacuum tube solar water heater control mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com