Temperature control system for large temperature difference adjustment of reflow soldering machine and temperature control method

A technology of temperature control system and reflow soldering machine, which is applied in the direction of manufacturing tools, welding equipment, printed circuit assembly of electrical components, etc. It can solve the problems of widening temperature difference, temperature difference control adjustment, slow cooling process, etc., and achieve accelerated cooling speed , The temperature difference adjustment is fast and the time-consuming effect is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

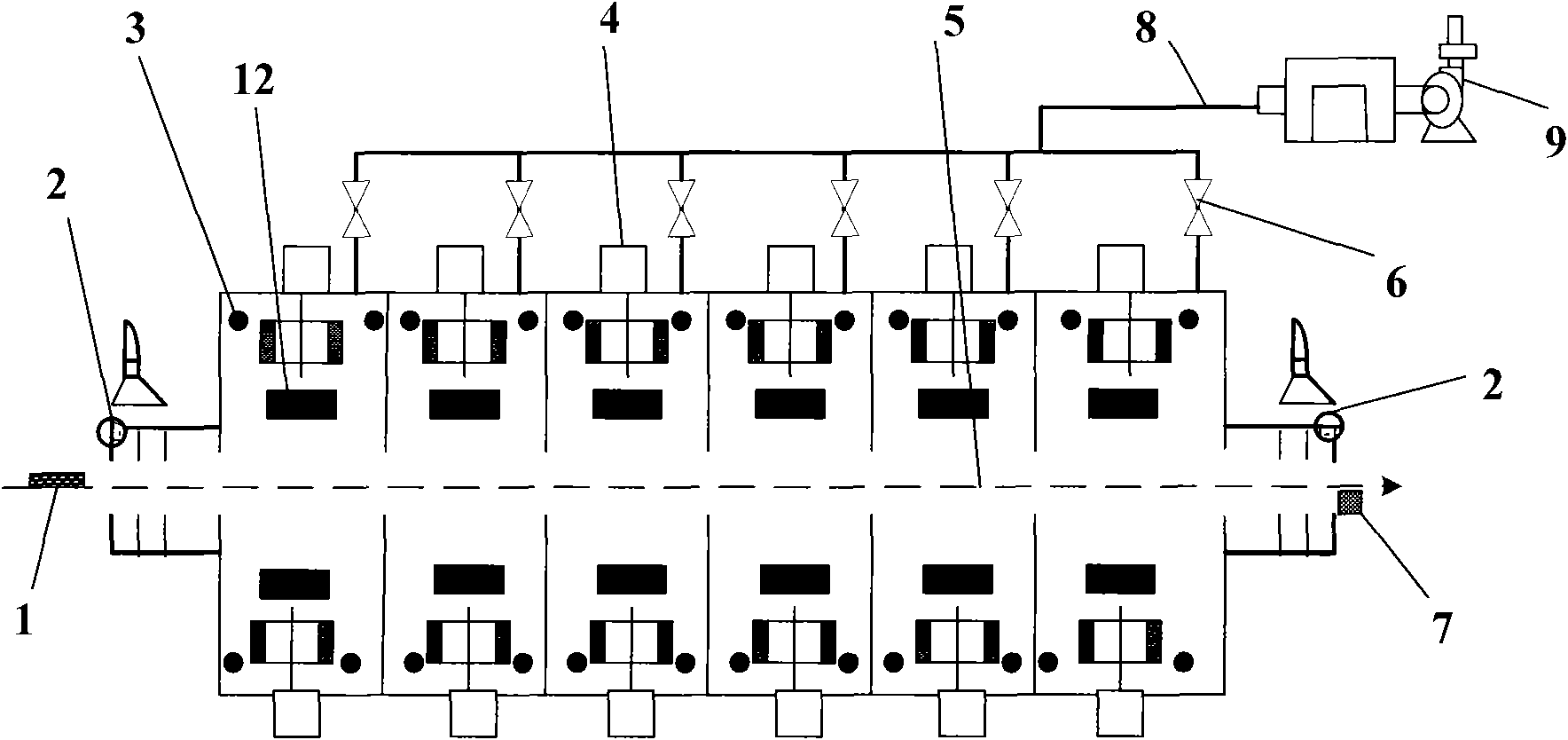

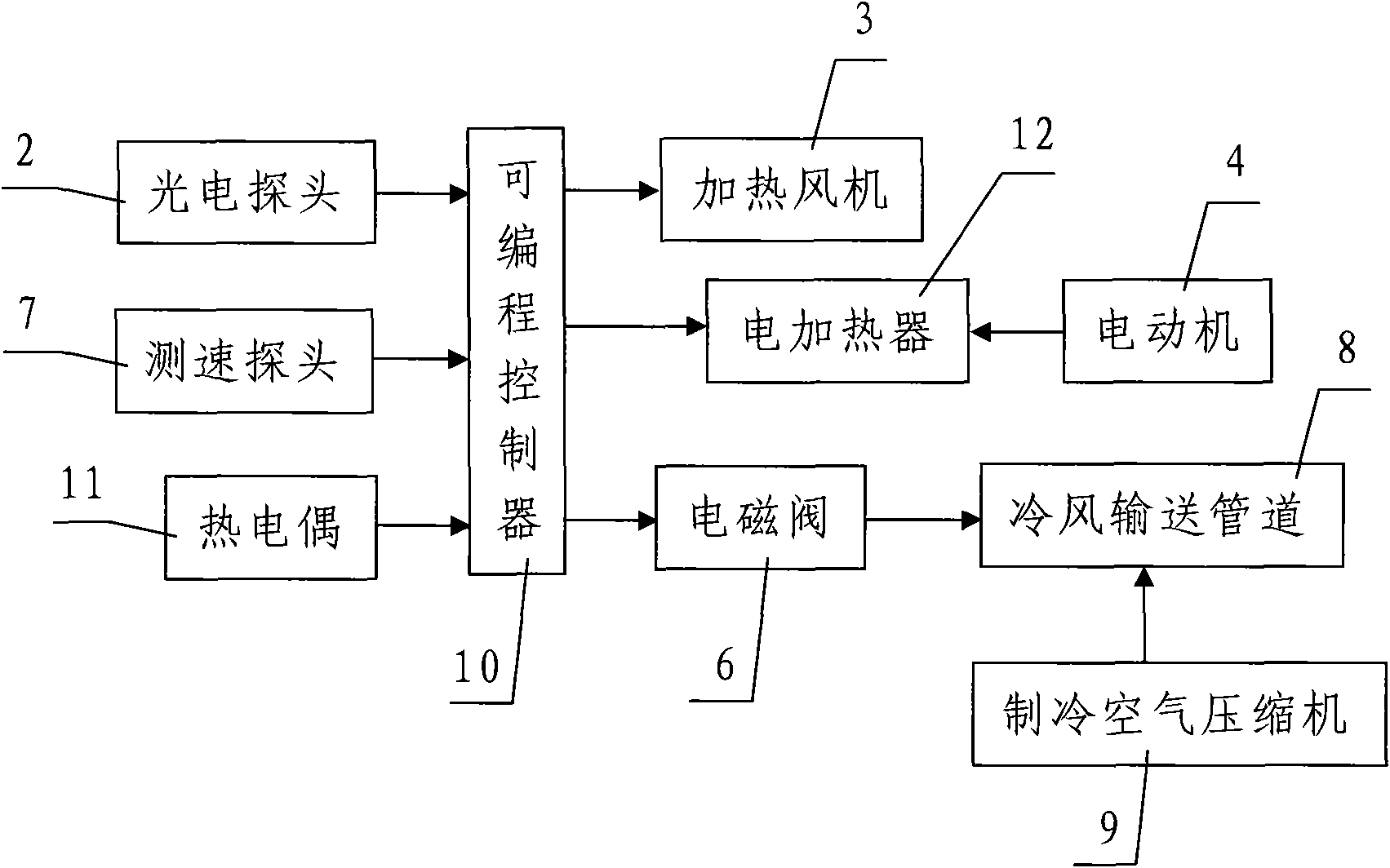

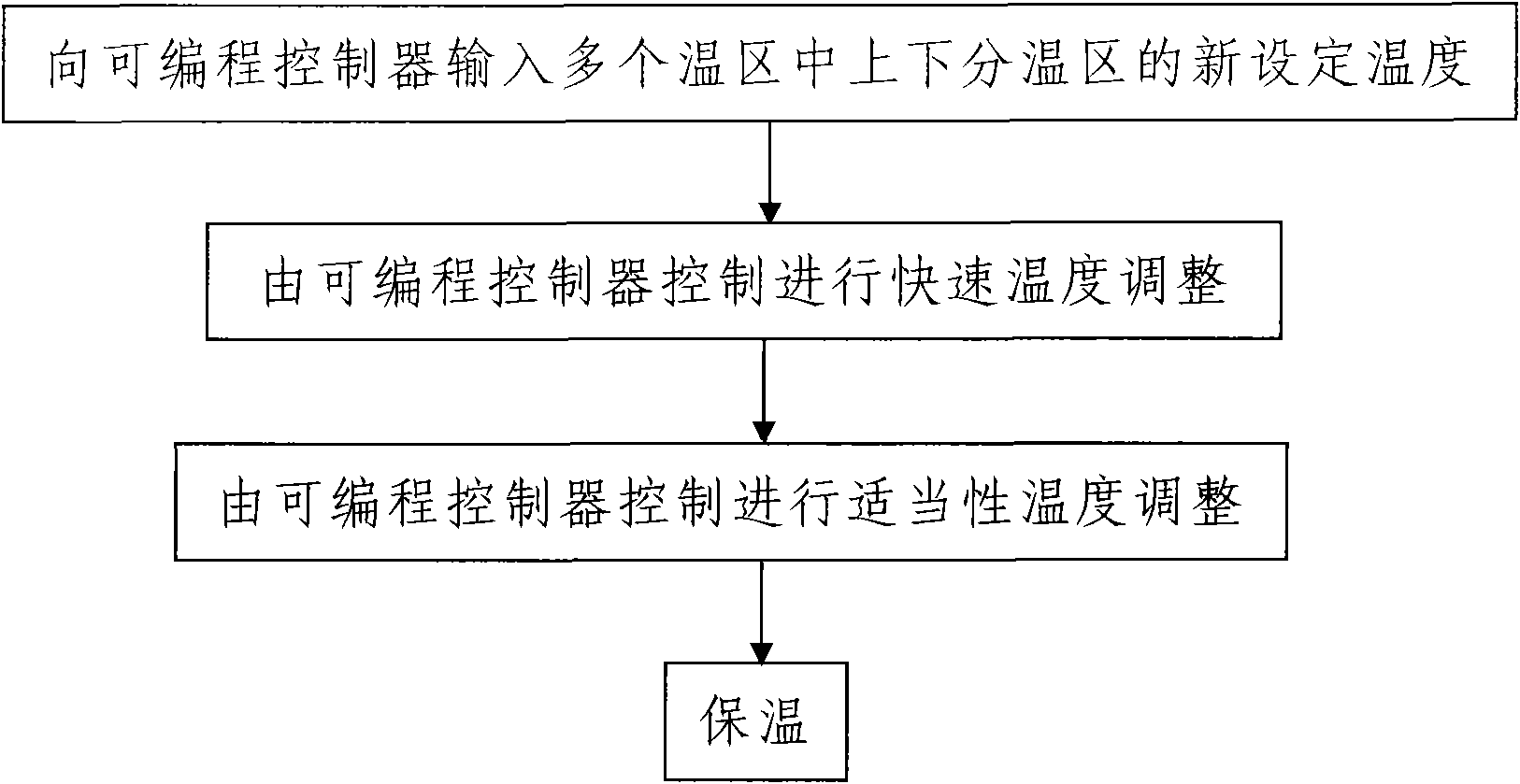

[0034] Such as figure 1 , figure 2 As shown, the temperature control system for adjusting the large temperature difference of the reflow soldering machine according to the present invention includes a programmable controller 10, a plurality of cold air conveying pipes 8, and a plurality of temperature zones of the reflow soldering machine through a plurality of cold air conveying pipes 8 A cooling system connected to each other and a plurality of electromagnetic valves 6 respectively installed on the plurality of cold air delivery pipes 8 . The plurality of solenoid valves 6 are all connected to the programmable controller 10 and their switch states and openings are controlled and regulated by the programmable controller 10. The number of temperature zones of the machine is the same. The plurality of temperature zones are divided into upper and lower temperature zones by the workpiece walking channel of the workpiece to be welded, and temperature detection units are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com