Cracking furnace for cracking hydrocarbon steam to prepare ethylene

A technology of cracking to produce ethylene and cracking furnace, applied in the field of petrochemical industry, can solve the problems of large land occupation and high investment of cracking furnace, and achieve the effects of uniform heating, improved operation cycle and good mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

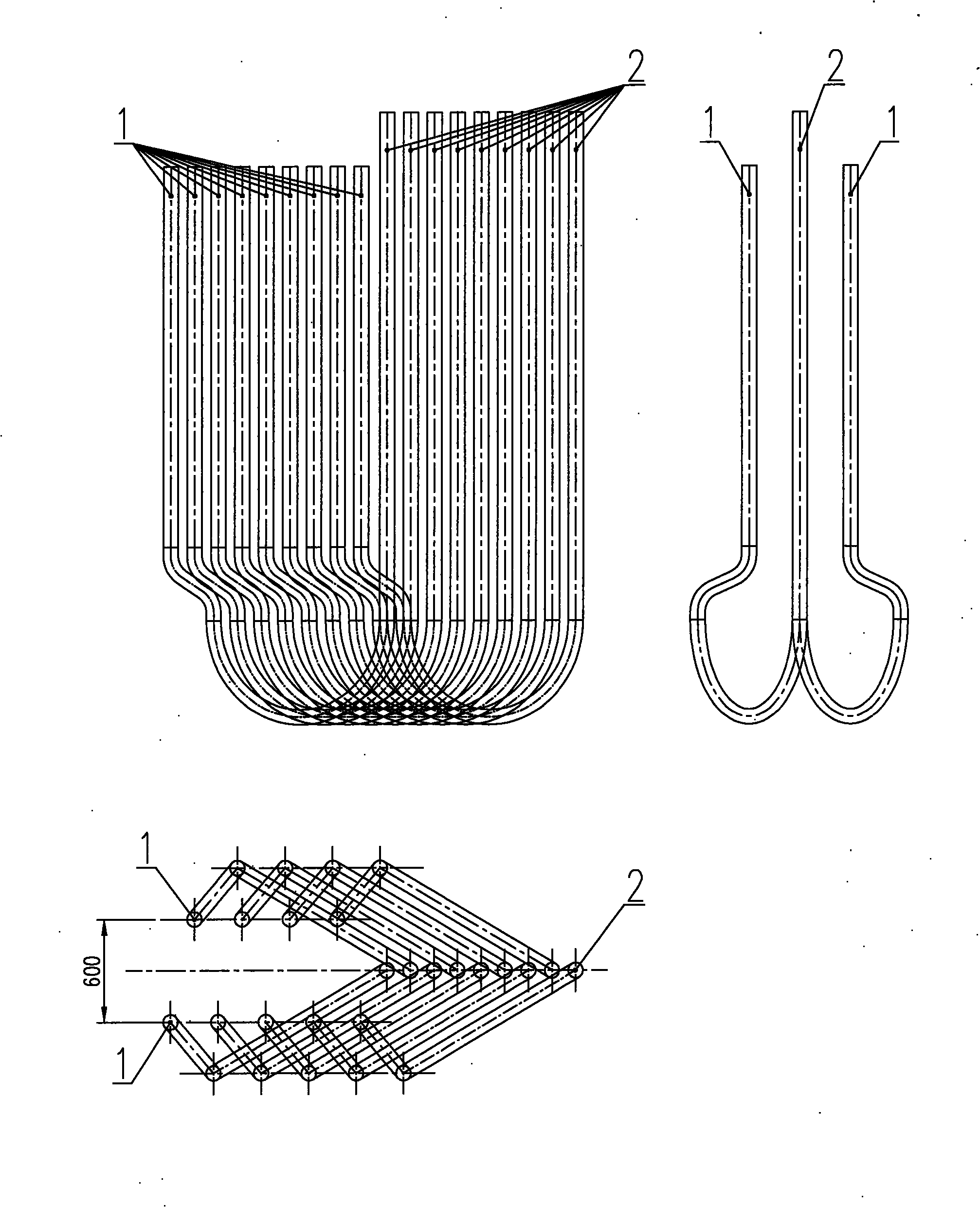

[0054] figure 2 It is one of the embodiments of the present invention.

[0055] Two-pass variable-diameter furnace tubes are used, in which the first-pass furnace tubes are arranged in double rows, respectively arranged in two parallel planes, and the distance between the two planes is 600mm. The furnace tubes of the second pass are arranged in a single row, and the furnace tubes of the first pass and the second pass are not on the same plane. The symmetrical elbow connecting the two-pass furnace tube extends out of the plane of the furnace tube. In the first pass, an S-bend tube is bent out of the furnace tube plane, and the angle between the bent part in the top view projection direction and the first pass furnace tube plane is determined according to the specific furnace tube number, tube diameter and tube row arrangement.

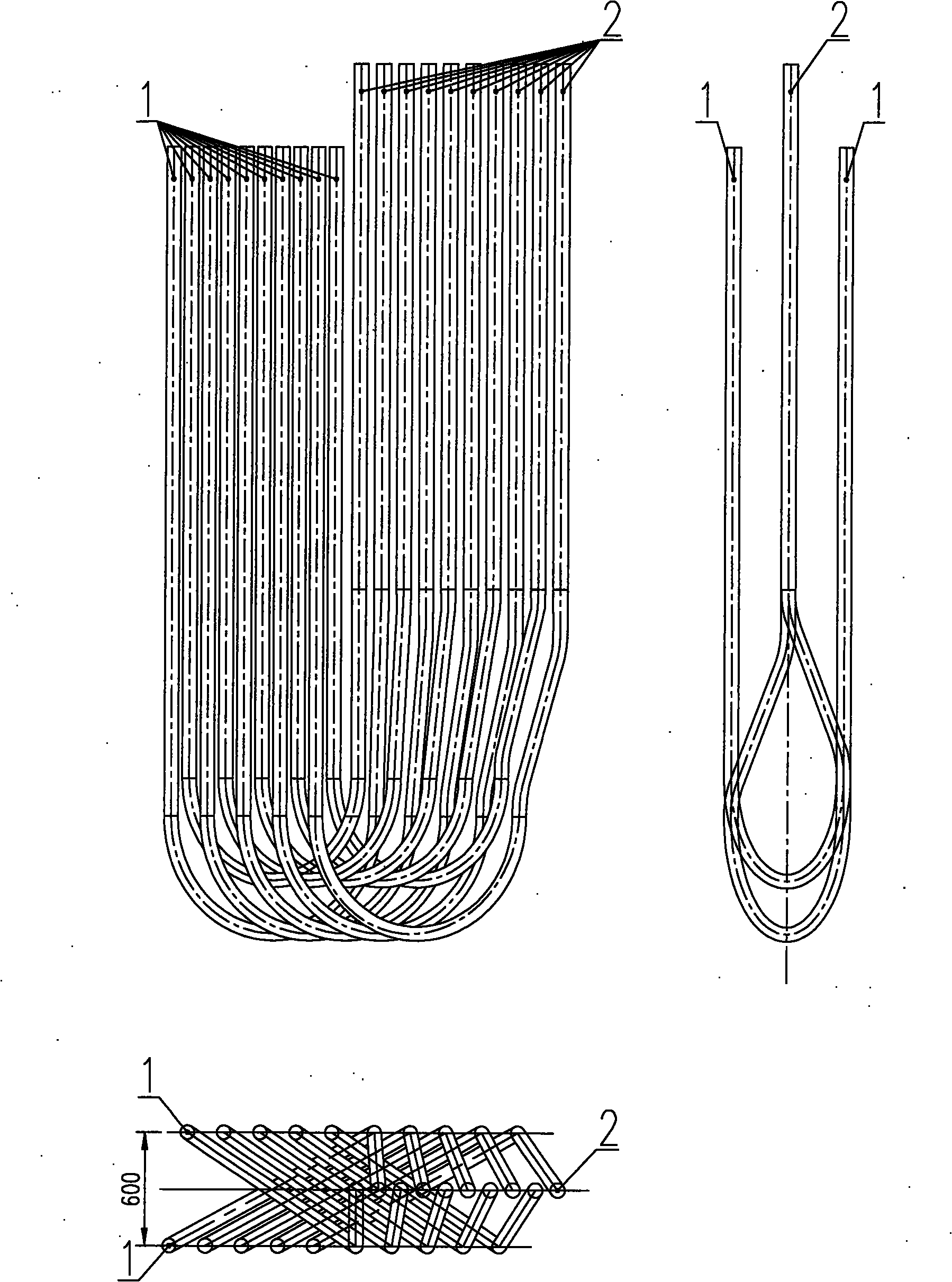

[0056] image 3 This is the second embodiment of the present invention.

[0057] Two-pass non-branching variable-diameter furnace tubes are used, of which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com