Optical adhesive composition, optical adhesive and optical film

A technology of adhesives and compositions, applied in the directions of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of low compatibility of acrylic polymers and lack of transparency of polarizers , to achieve the effects of excellent transparency, suppression of light leakage, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0065] The first embodiment of the present invention is an optical adhesive composition containing the following (A) to (D) components.

[0066] (A) 100 parts by weight of a (meth)acrylate polymer having a weight average molecular weight of 200,000 to 2,500,000

[0067] (B) 1 to 50 parts by weight of a reactive (meth)acrylate polymer having a weight average molecular weight of 30,000 to 1,500,000 and having an ethylenic double bond in a side chain

[0068] (C) 0.1 to 50 parts by weight of polyfunctional (meth)acrylate compound

[0069] (D) 0.01 to 10 parts by weight of photopolymerization initiator

[0070] Hereinafter, the first embodiment of the present invention will be specifically described with reference to the accompanying drawings as appropriate.

[0071] 1. (A) Ingredient

[0072] (1) Type

[0073] (A) Component is a (meth)acrylate polymer, and is a so-called acrylic polymer.

[0074] Moreover, as a point different from (B) component mentioned later, (A) componen...

no. 2 Embodiment approach

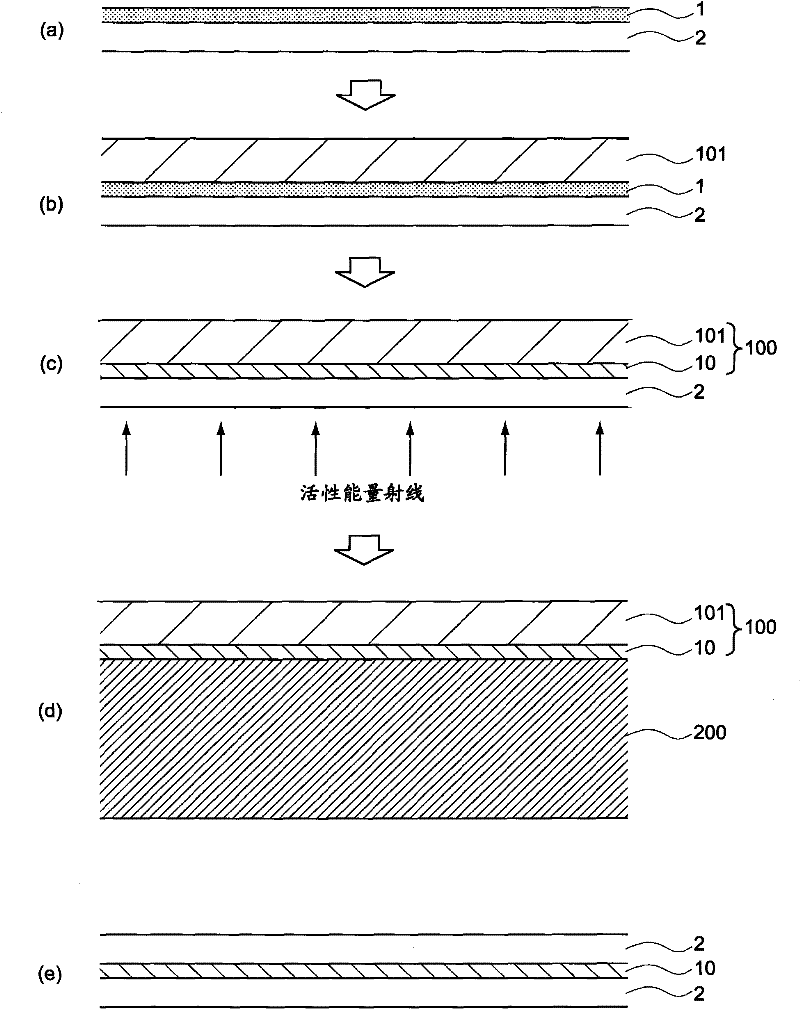

[0198] A second embodiment of the present invention is an optical adhesive obtained by curing an optical adhesive composition, wherein the optical adhesive is obtained through steps (1) to (3). form.

[0199] (1) Step of preparing an optical adhesive composition containing the following (A) to (D) components

[0200] (A) 100 parts by weight of a (meth)acrylate polymer having a weight average molecular weight of 200,000 to 2,500,000

[0201] (B) 1 to 50 parts by weight of a reactive (meth)acrylate polymer having a weight average molecular weight of 30,000 to 1,500,000 and having an ethylenic double bond in a side chain

[0202] (C) 0.1 to 50 parts by weight of polyfunctional (meth)acrylate compound

[0203] (D) 0.01 to 10 parts by weight of photopolymerization initiator

[0204] (2) The step of applying the optical adhesive composition to the release film

[0205] (3) 50~1000mJ / cm 2 The step of irradiating an active energy ray with an irradiation dose within the range to obt...

no. 3 Embodiment approach

[0252] A third embodiment of the present invention is an optical film comprising an adhesive layer containing the optical adhesive of the second embodiment on a film base material, wherein the adhesive is The thickness of the layer is set to a value within the range of 1 to 100 μm.

[0253] Below, refer to figure 1 A third embodiment of the present invention will be specifically described.

[0254] 1. Film substrate

[0255] The film base material 101 in the optical film 100 of the present invention is not particularly limited as long as it is a film base material used for an optical film.

[0256] For example, optical films used for liquid crystal displays, such as a polarizing plate, a polarizing layer protective film, a viewing angle widening film, an antiglare film, a retardation film, etc. are mentioned.

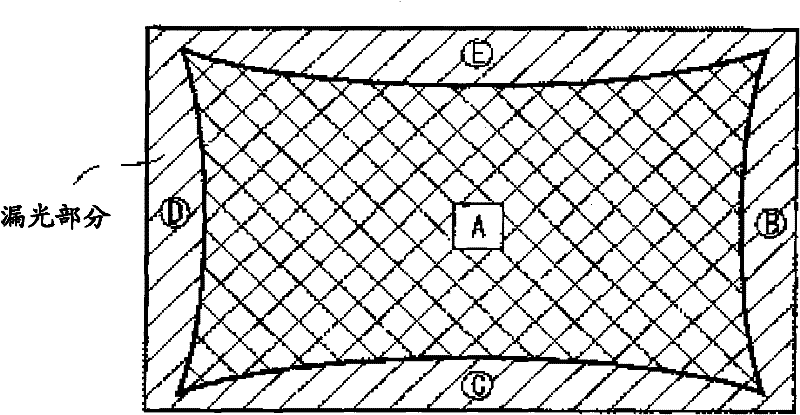

[0257] In particular, as long as it is the optical film of the present invention, even when the film base material is a polarizer, the occurrence of light leakage ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com