Substrate film-coating processing system

A processing system and substrate technology, applied in the direction of sputtering plating, ion implantation plating, vacuum evaporation plating, etc. Thickness of sheet coating and other issues to achieve the effect of improving coherence and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

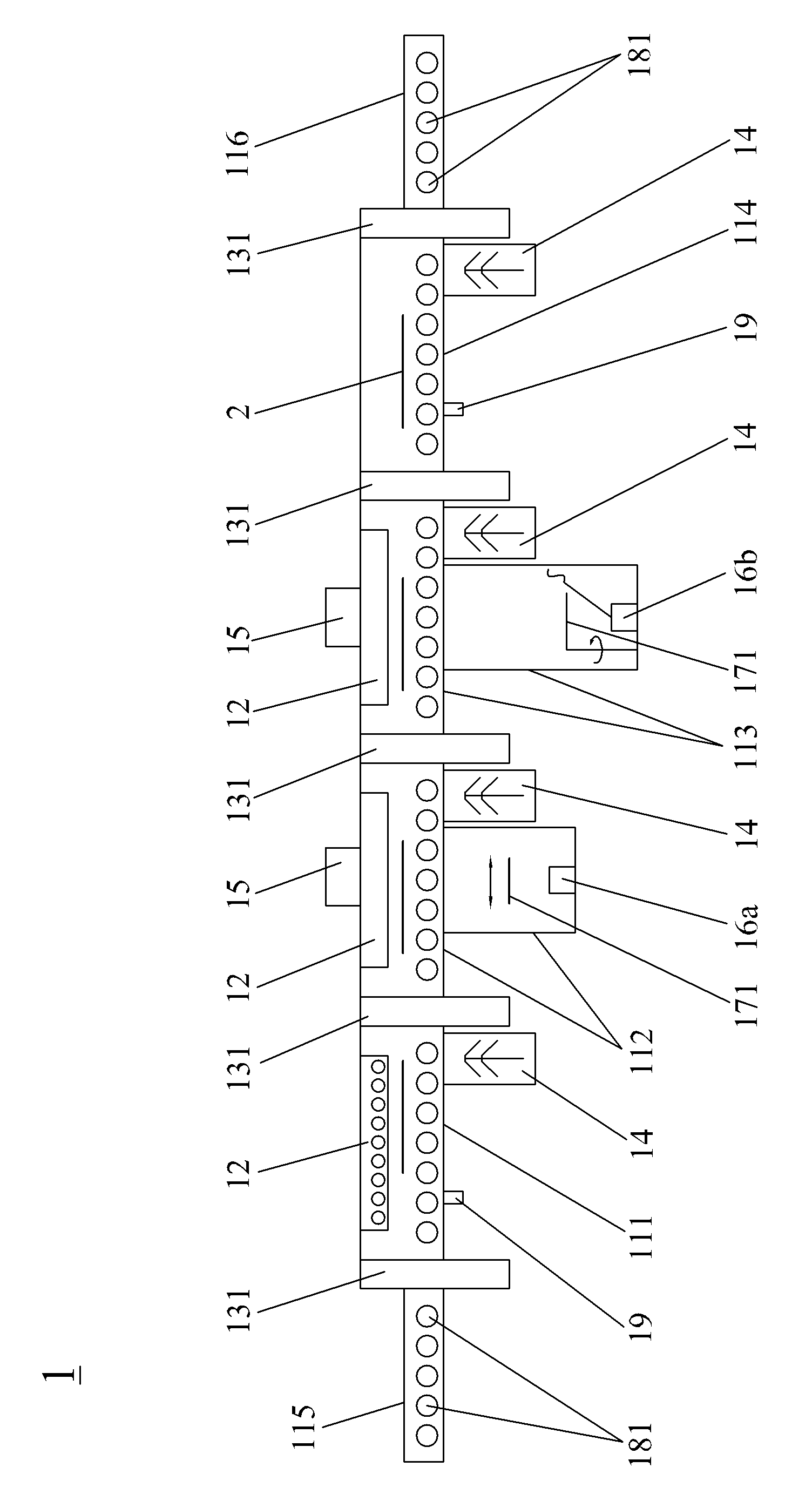

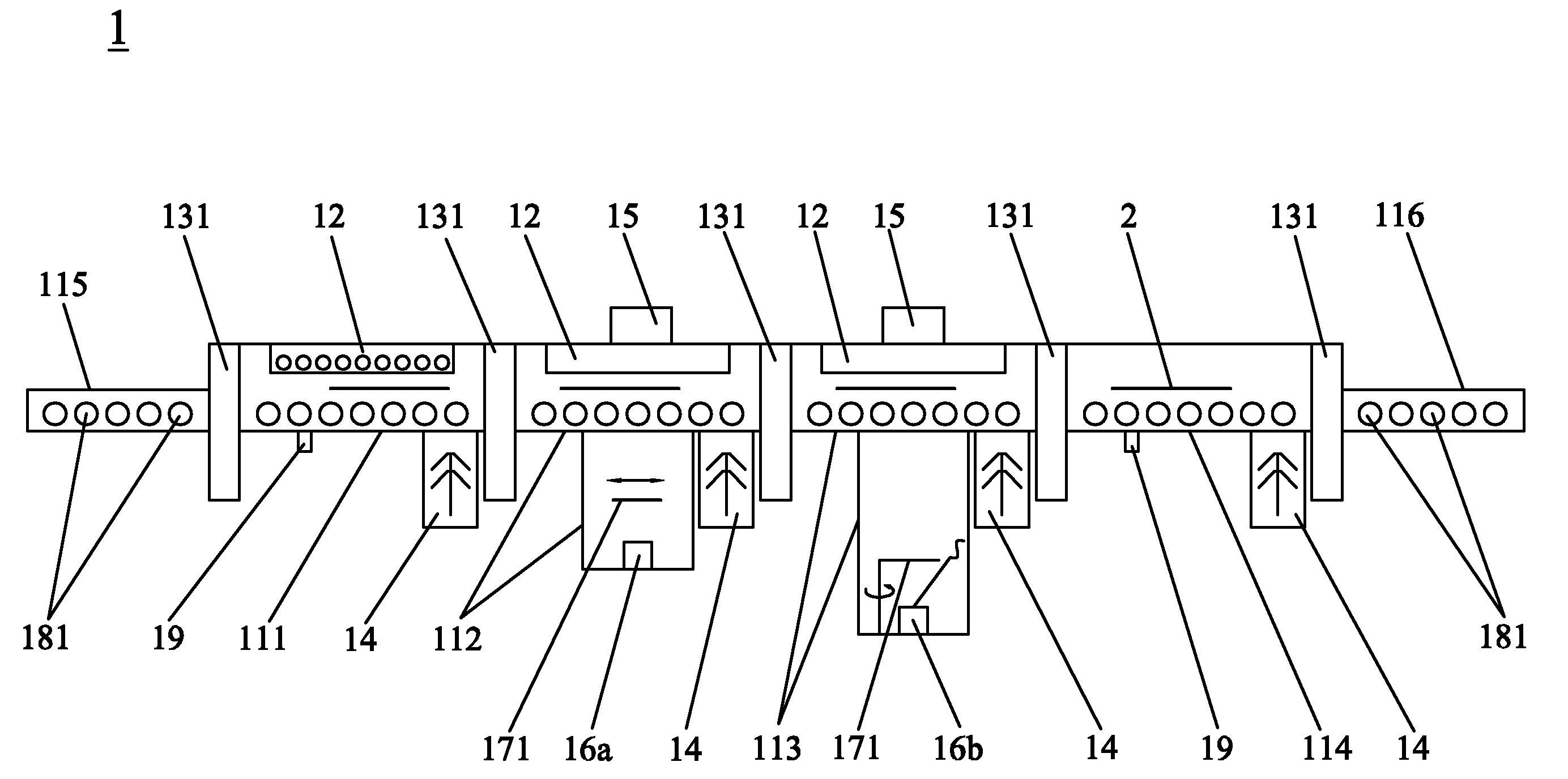

[0017] see figure 1 , The substrate coating processing system 1 of the present invention includes a cavity, a heating device 12, a gate valve assembly, a substrate transmission device, a vacuum device 14, a film thickness detector 15, an evaporation source and a controller. The cavity includes an initial heating cavity 111, an organic coating cavity 112, an inorganic coating cavity 113, and a cooling cavity 114 that are connected to each other and are hollow in turn. The initial heating cavity 111 is connected with a feeding cavity 115, and the cooling cavity 114 is connected with a discharge chamber 116, and the feed chamber 115, the initial heating chamber 111, the organic coating chamber 112, the inorganic coating chamber 113, the cooling chamber 114 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com