Preparation method of bamboo cellulose oily gauze dedicated for external wound

A bamboo cellulose and bamboo fiber technology, which is applied in the field of medical supplies, can solve the problems that the dressing cannot be naturally degraded, the protein stabilizer is not very stable, and the storage is difficult, so as to prevent bacteria from infecting wounds, prevent infection and heal well. , The effect of treating the sterilization thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

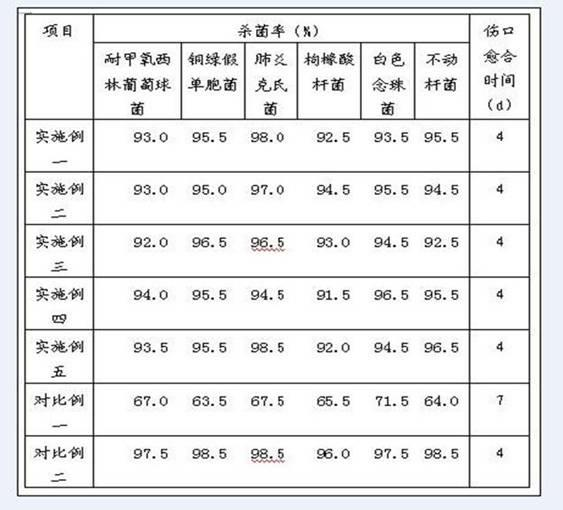

Examples

Embodiment 1

[0030] A preparation method of special bamboo cellulose oil yarn for external wounds, comprising the following steps:

[0031] 1. bamboo fiber yarn is made into a mesh-shaped belt-shaped base cloth with seams after rinsing, and the width of the base cloth is 5 cm;

[0032] ②Immerse the above-mentioned base cloth in the finishing solution, dry and sterilize;

[0033] ③ Dry the sterilized base cloth, and then coat the base cloth with a mixed emulsion of vaseline and paraffin as the main components;

[0034] ④ Cut the base cloth coated with the mixed emulsion of vaseline and paraffin as the main components first, and then pack it with a good airtight aseptic sheet packaging material in a double-sided clamping method;

[0035] ⑤ Radiation sterilization step: the bamboo fiber base cloth coated with vaseline and paraffin as the main components of the mixed emulsion with aseptic packaging materials on both sides is sterilized by radiation with Co60.

[0036] In the above steps, the c...

Embodiment 2

[0040] A preparation method of special bamboo cellulose oil yarn for external wounds, comprising the following steps:

[0041] 1. after rinsing the bamboo fiber yarn, make the mesh-type belt-shaped base cloth of seaming, and the width of this base cloth is 8cm;

[0042] ②Dry and sterilize the base cloth after soaking it in the finishing solution;

[0043] ③ Dry the sterilized base cloth, and then coat the base cloth with a mixed emulsion of vaseline and paraffin as the main components;

[0044] ④ Cut the base cloth coated with the mixed emulsion of vaseline and paraffin as the main components first, and then pack it with a good airtight aseptic sheet packaging material in a double-sided clamping method;

[0045] ⑤ Radiation sterilization step: the bamboo fiber base cloth coated with vaseline and paraffin as the main components of the mixed emulsion with aseptic packaging materials on both sides is sterilized by radiation with Co60.

[0046] In the above steps, the components...

Embodiment 3

[0050] A preparation method of special bamboo cellulose oil yarn for external wounds, comprising the following steps:

[0051] 1. after rinsing the bamboo fiber yarn, make the mesh-shaped belt-shaped base cloth of seaming, and the width of this base cloth is 10cm;

[0052] ②Dry and sterilize the base cloth after soaking it in the finishing solution;

[0053] ③ Dry the sterilized base cloth, and then coat the base cloth with a mixed emulsion of vaseline and paraffin as the main components;

[0054] ④ Cut the base cloth coated with the mixed emulsion of vaseline and paraffin as the main components first, and then pack it with a good airtight aseptic sheet packaging material in a double-sided clamping method;

[0055] ⑤ Radiation sterilization step: the bamboo fiber base cloth coated with vaseline and paraffin as the main components of the mixed emulsion with aseptic packaging materials on both sides is sterilized by radiation with Co60.

[0056] In the above steps, the compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com