Digital display standard metal measuring apparatus for continuous measurement

A standard metal gauge and measurement standard technology, which is applied in the field of digital display continuous measurement standard metal gauge, can solve the problems of multiple errors and increase of measurement errors, so as to reduce operation errors, ensure fairness and fairness of measurement, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

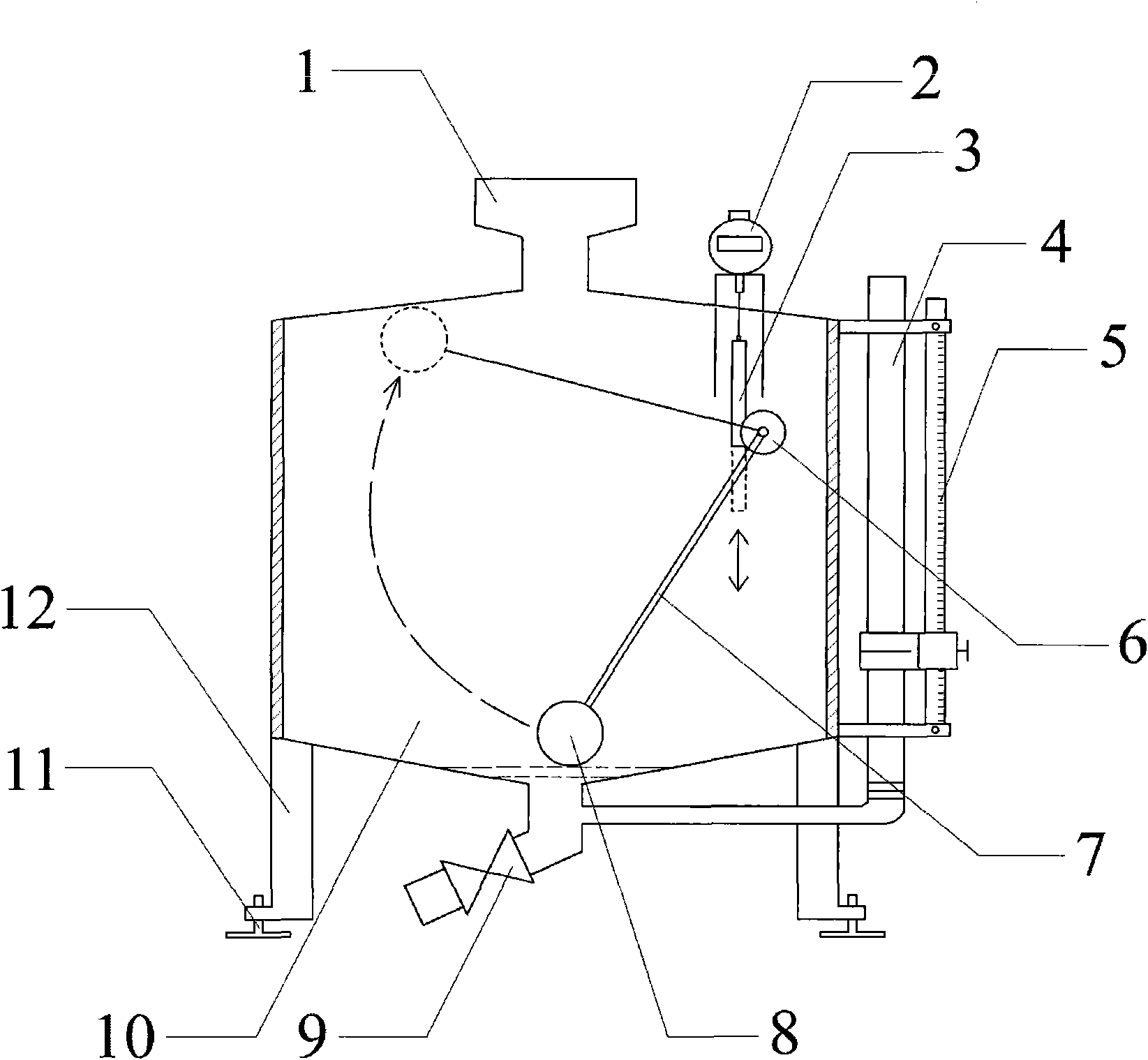

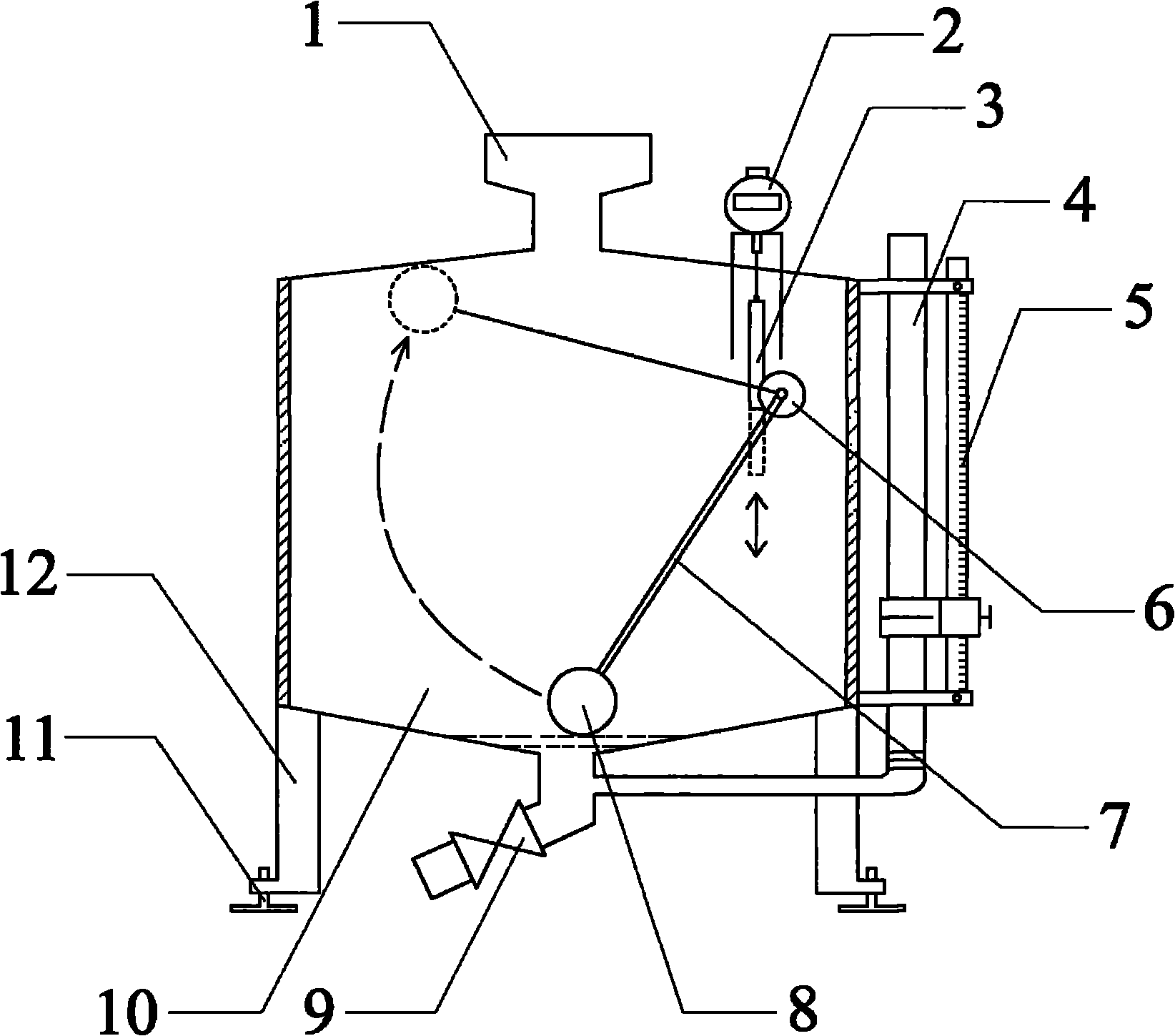

[0019] A digital display type continuous measurement standard metal gauge, its structure is as follows figure 1 As shown, the device consists of a liquid contact funnel 1, a digital display dial gauge 2, an ejector rack 3, a liquid level glass tube 4, a vernier caliper 5, a gear 6, a connecting rod 7, a float 8, a drain valve 9, and a standard The metal gauge 10, the horizontal adjustment seat 11 and the gauge bracket 12 are composed, the liquid contact funnel 1 is set on the top of the standard metal gauge 10, the digital display dial indicator 2 is set on one side of the liquid contact funnel 1, and the ejector rod rack 3 is connected to the lower part of the digital display dial indicator 2, the gear 6 is connected to the ejector rack 3, the float 8 is connected to the gear 6 through the connecting rod 7, and the liquid level glass tube 4 is set on one side of the standard metal gauge 10 , the lower part communicates with the drain valve 9, the drain valve 9 is set at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com