System for monitoring vibration of rotating machinery rolling bearing in wireless mode

A rolling bearing and wireless vibration technology, applied in the detection field, can solve the problems of inconvenient installation, use and maintenance, single performance of ultrasonic flaw detector, scalability and poor maintainability, and achieve simple structure, reliable performance and anti-interference powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

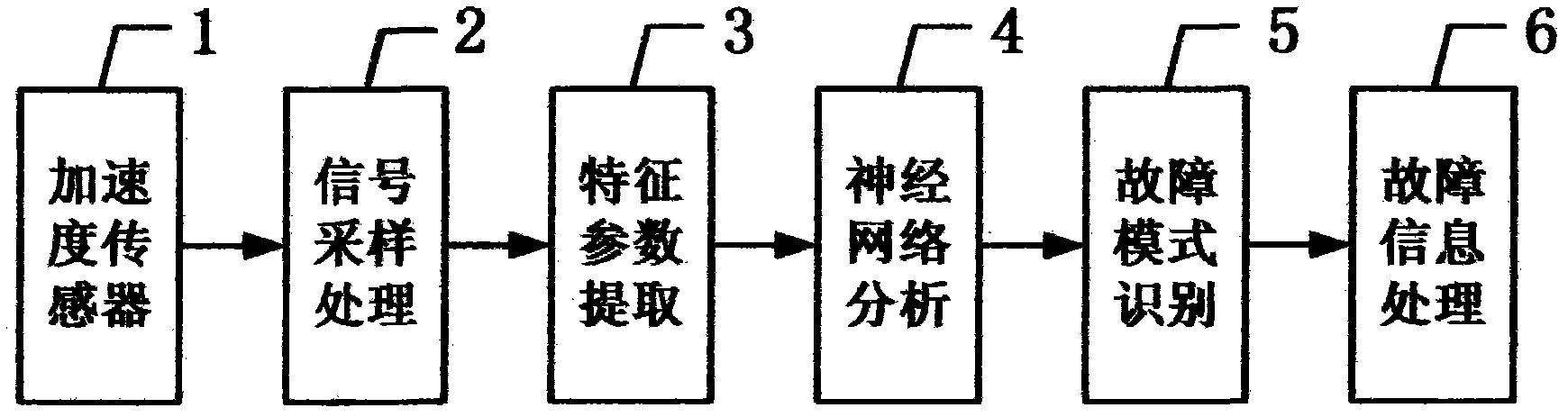

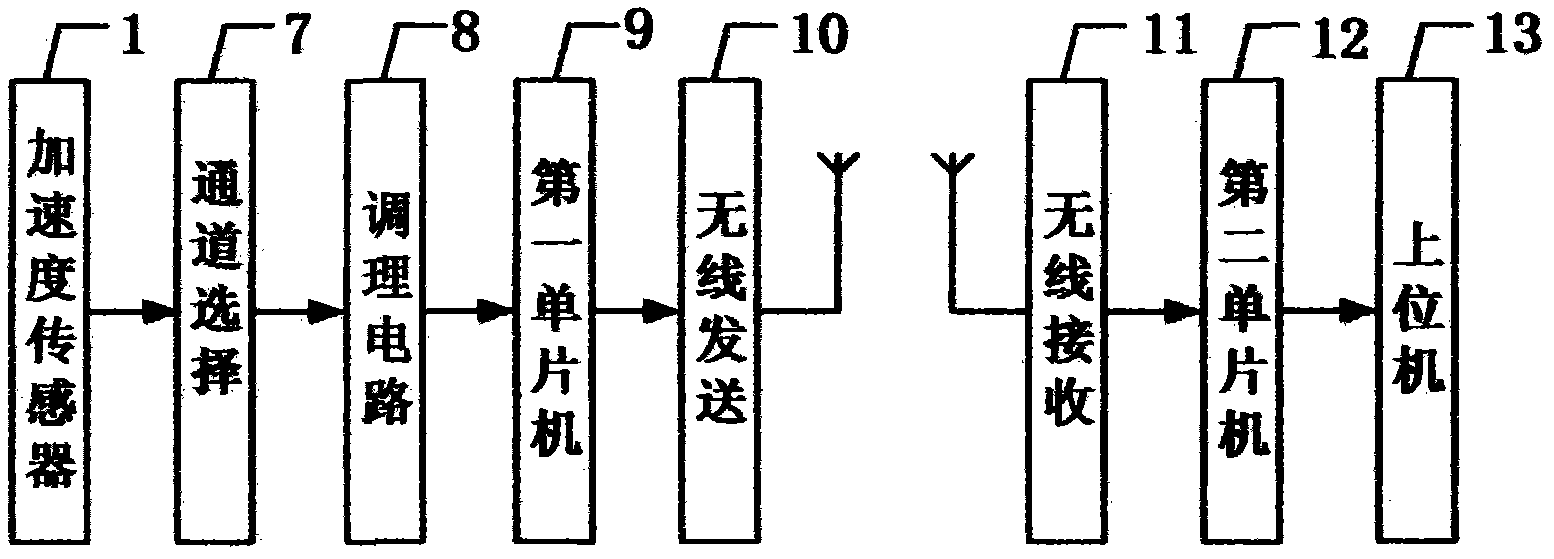

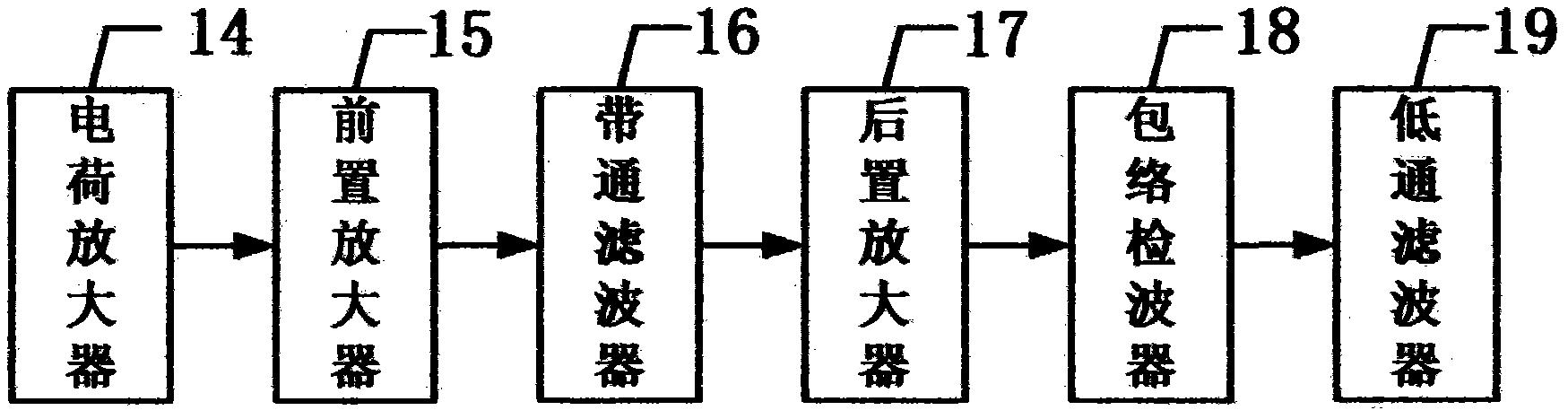

[0012] The present invention will be further described below through specific examples. Such as figure 1 As shown, this embodiment includes three parts: sending, receiving and upper computer analysis and processing. Acceleration sensors 1 are respectively installed at three test points; channel selection 7 is composed of CD4514 gate driven relay after ULN2003A power amplification; conditioning circuit 8 (such as image 3 Shown) consists of charge amplifier 14, preamplifier 15, bandpass filter 16, postamplifier 17, envelope detector 18, low pass filter 19. The charge amplifier 14 operational amplifier selects OP07; the preamplifier 15 and postamplifier 16 select the instrumentation amplifier AD620 for use; the bandpass filter 16 is a second-order bandpass active filter with a center frequency of 5kHz and a bandwidth of 500Hz; the envelope detector 18 is composed of The low-pass filter 19 is a Sallen-Key second-order low-pass filter with a cutoff frequency of 10 kHz. The ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com