Automatic leaching method for soil column simulation test

A simulation test and soil technology, applied in soil material testing, material inspection products, etc., can solve the problems of artificial water injection not too much at a time, unscientific, and high manual physical effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with accompanying drawing.

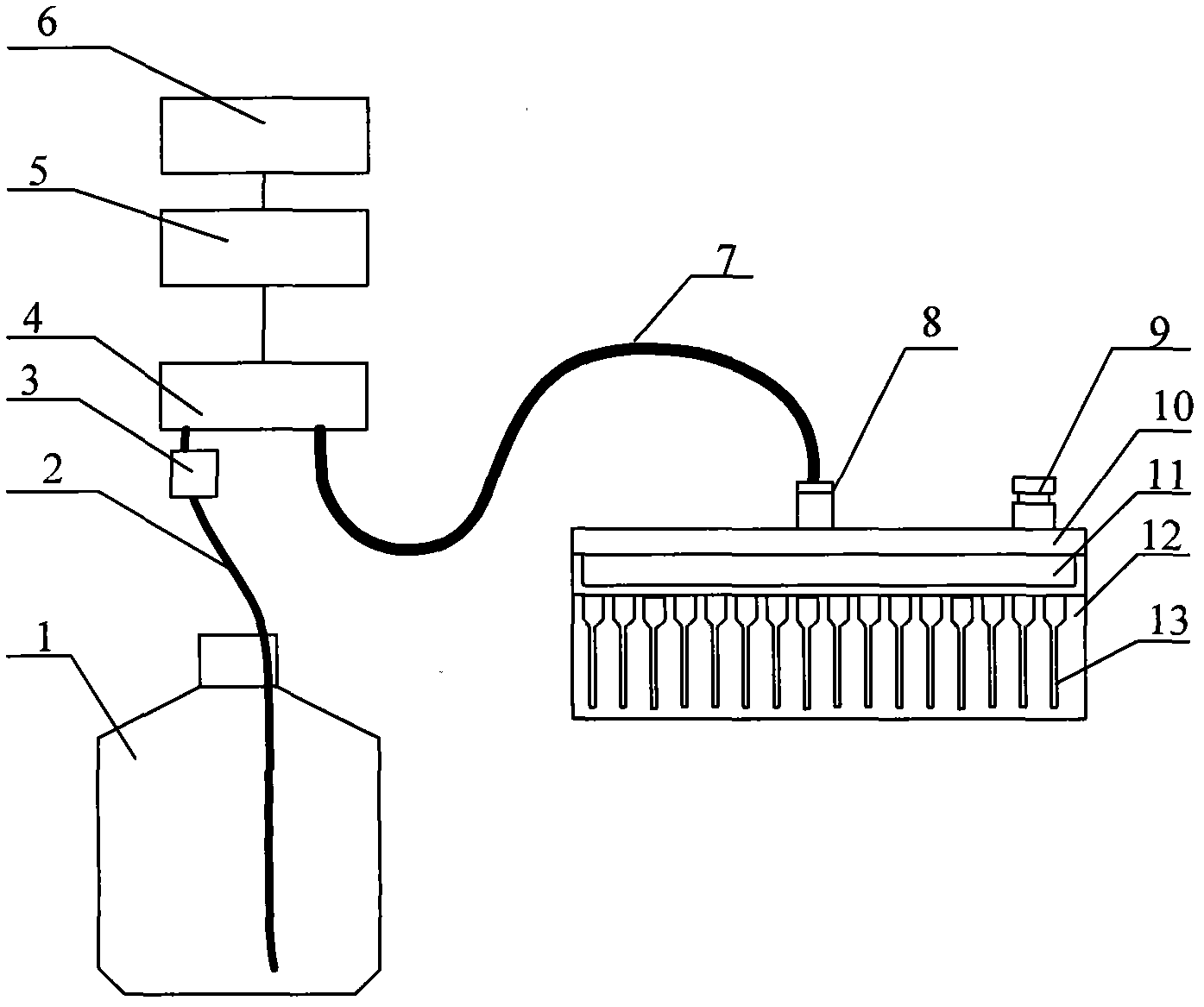

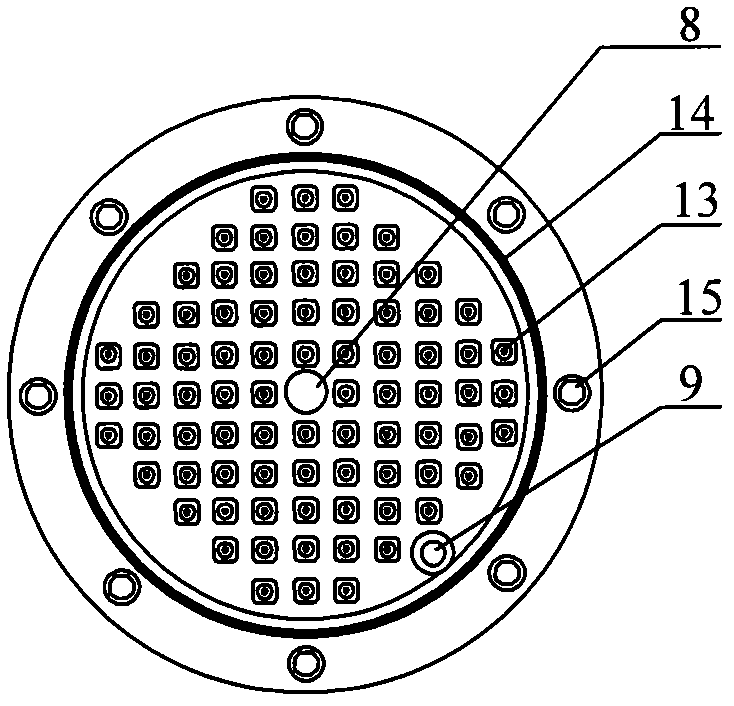

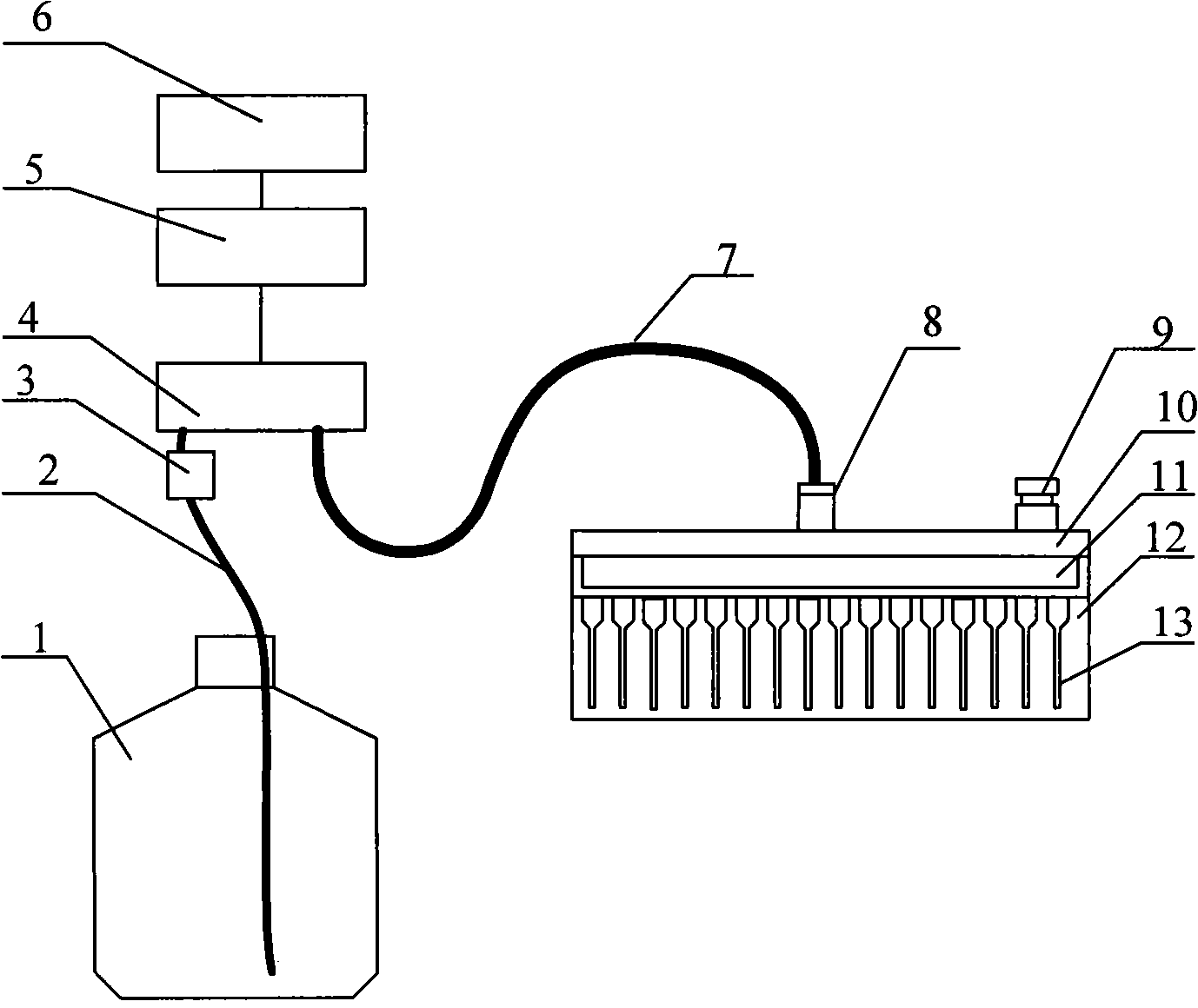

[0016] An automatic leaching method for a soil column simulation test according to the present invention, the devices involved in the method are: a water storage tank, a water pump, a water shortage sensor, a peristaltic pump head, a peristaltic pump controller, an LCD display and buttons, Composed of water injection pipe, universal quick connector, exhaust valve, transparent upper cover, shower seat cavity, transparent protective shell, syringe needle, sealing ring and fixing screws, the water storage tank 1 passes through the suction pipe 2 and the peristaltic pump head 4 Connection, the water shortage sensor 3 is installed on the suction pipe 2, one end of the peristaltic pump controller 5 is connected to the peristaltic pump head 4, and the other end is connected to the LCD display 6, and the peristaltic pump head 4 passes through the water injection pipe 7 and the universal connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com