Online state monitoring and fault diagnosis device and method for rotary machine

A technology for fault diagnosis devices and rotating machinery, applied in measuring devices, testing of machine/structural components, computer components, etc., can solve problems such as difficult to achieve early diagnosis and prevention of faults, difficult to meet the needs of diagnosis, etc., to achieve a rich state Monitoring and fault diagnosis methods, clear functions, and the effect of improving online monitoring and fault diagnosis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

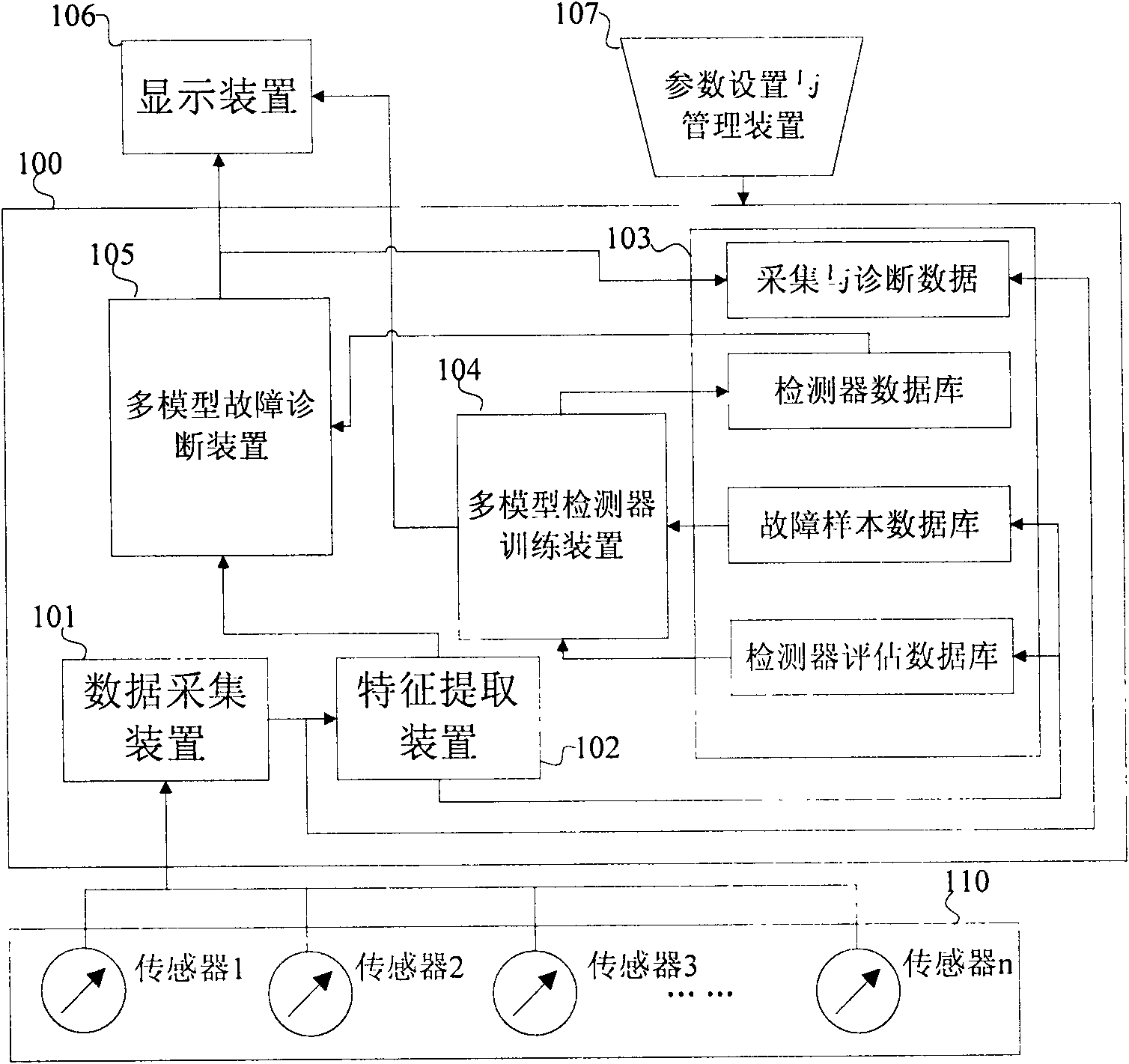

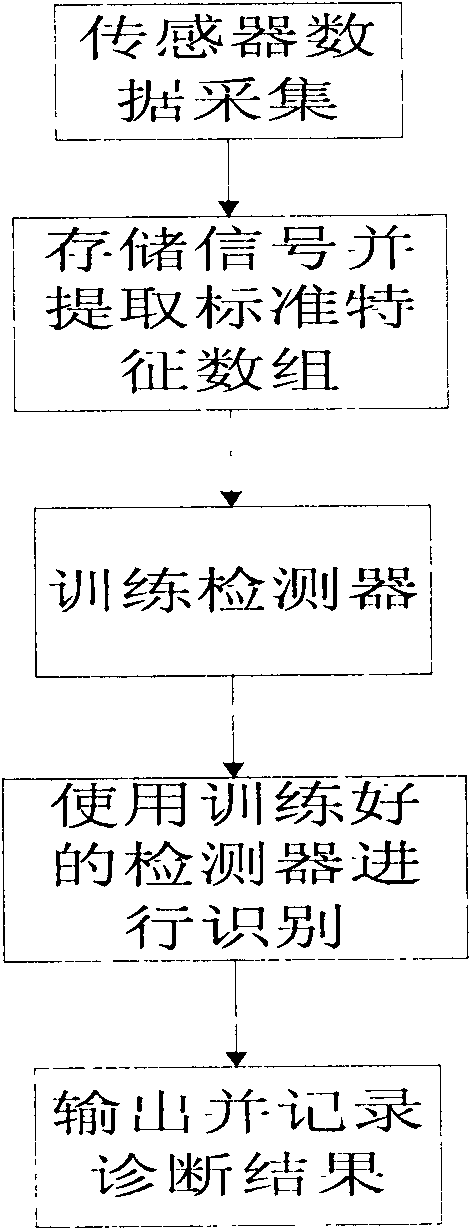

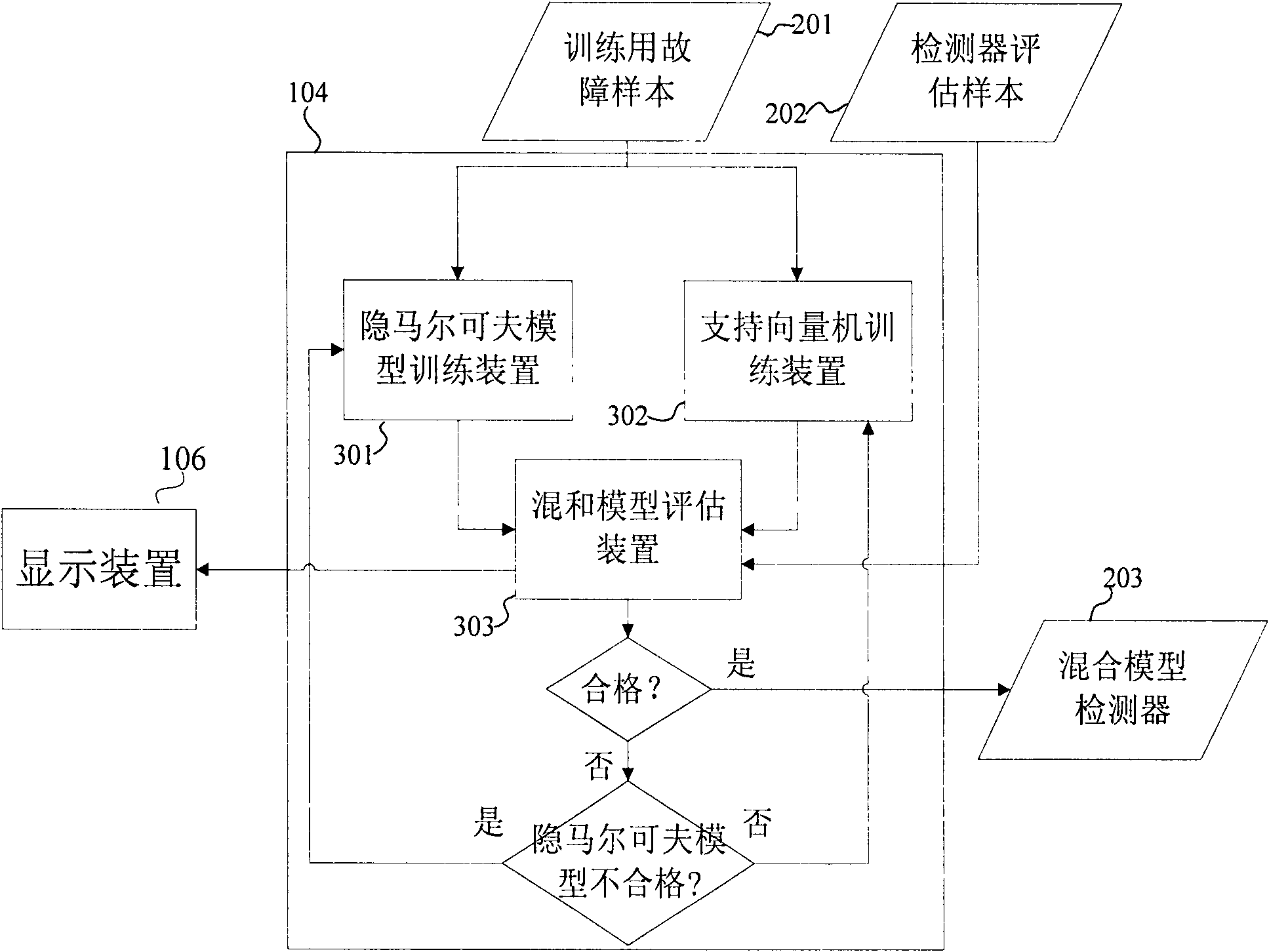

[0043] Such as figure 1 It shows the structure of an on-line monitoring and fault diagnosis device of the present invention. The device is a portable rapid diagnostic equipment, all functions are concentrated on a portable machine, suitable for rapid diagnosis or preliminary diagnosis by professional researchers related to fault diagnosis. The device includes a data acquisition device 101, a feature extraction device 102, a data management device 103, a multi-model detector training device 104, a multi-model fault diagnosis device 105, a display device 106, and a mouse, keyboard and other users to set parameters 107 with device management means. In the embodiment of the portable rapid diagnostic device, the sensor group 110 can be configured by the user.

[0044] The data acquisition device 101 collects the signals of the sensor group 110 (including n signals of sensor 1, sensor 2, ..., sensor n on the same device) according to the sensor installation and data acquisition sc...

Embodiment 2

[0132] Figure 9 An embodiment of on-line monitoring and fault diagnosis based on a hidden Markov model-support vector machine hybrid model using two industrial computers is described. This example is used for online monitoring and fault diagnosis of a single device or a small number of devices. One of the industrial computers is a collection and diagnosis machine 901, and the other industrial computer 902 is used as a detector training machine.

[0133] The collection and diagnosis machine 901 integrates data collection and diagnosis functions. Compared with Embodiment 1, 901 does not have a multi-model detector training device 104 . At the same time, the data management device of 901 is simplified as the management device 903 for collecting and diagnosing data, which is only responsible for managing detectors and collecting and diagnosing data. The data collected by the data collection device 101 is saved on the collection and diagnosis machine 901 . Periodically or when...

Embodiment 3

[0137] Figure 10 An embodiment of using the present invention to carry out on-line monitoring and fault diagnosis by adopting multiple diagnostic subsystems is described. This example is used in the embodiment of centralized online monitoring and fault diagnosis of multiple devices or large-scale devices. The example consists of a detector training machine 902, a main control machine 1001, multiple collection and diagnosis extension machines 1003-1005 and sensor groups 1011-1013, and is composed of MAP or TCP / IP bus. The structure of the detector training machine 902 is as shown in Embodiment 2, and the structure of the collection and diagnosis extensions 1003-1005 is the same as that of 901 in Embodiment 2; only their communication devices need to support the bus. The main control machine 1001 is specially responsible for the integration of the diagnosis results and the management of the database, that is, the strengthening of the function of the data management device 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com