Battery with specific structure and manufacturing method thereof

A technology for batteries and battery casings, applied in secondary battery manufacturing, secondary batteries, structural parts, etc., can solve problems such as unrealizable, increase in total battery volume, and inconspicuous effects, so as to improve uniformity and improve charge and discharge Efficiency, temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

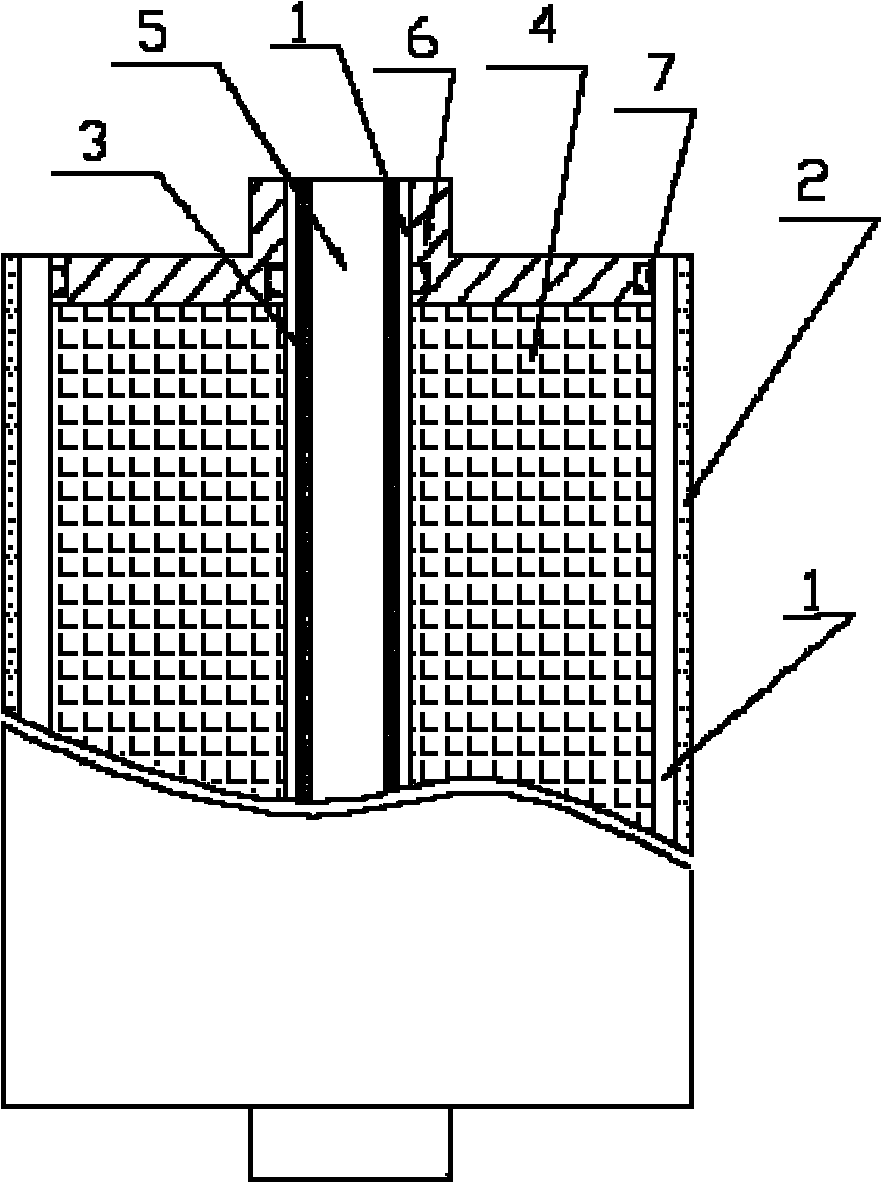

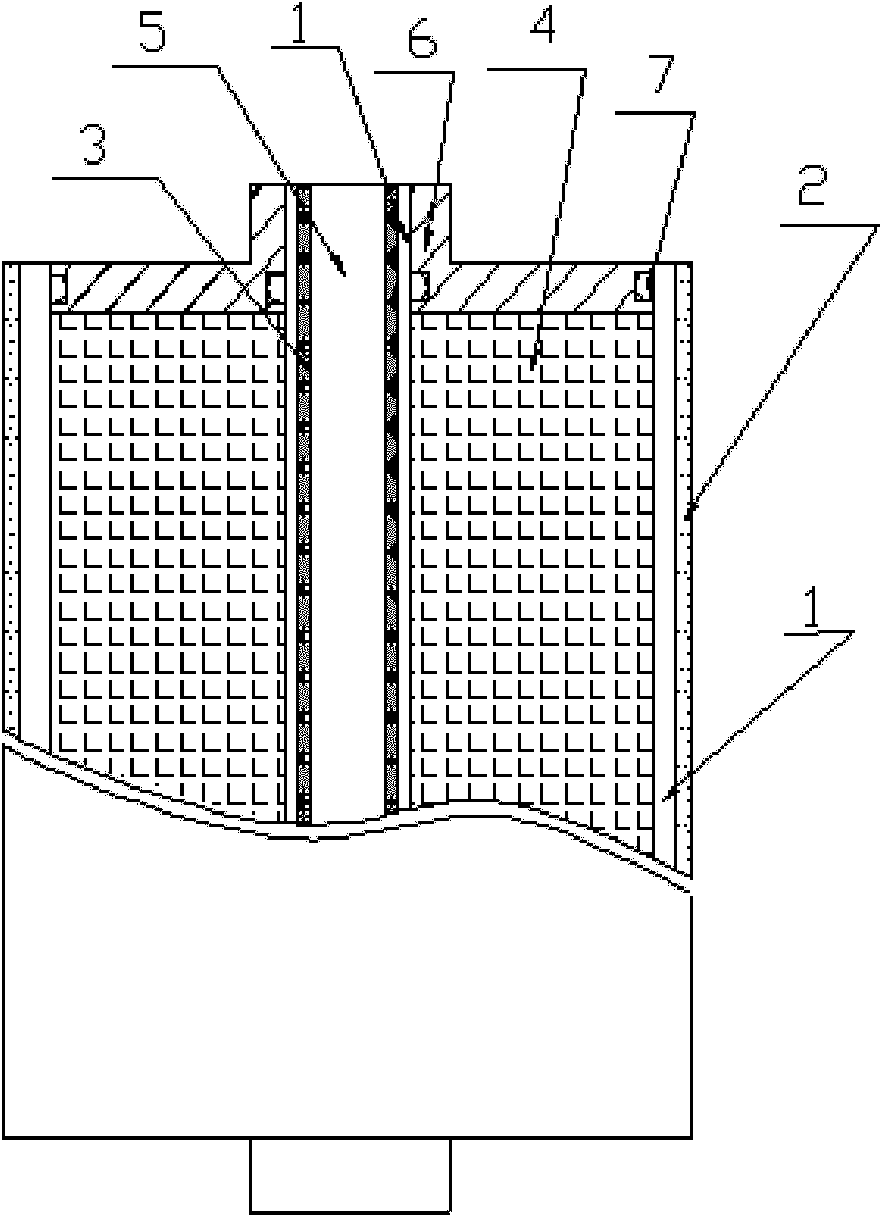

[0013] A round nickel-hydrogen battery with a design capacity of 100Ah. The structure plan is as figure 1 As shown, the pole group 4 is placed in the battery case 2 made of stainless steel. There is an insulating sleeve 1 between the pole group 4 and the battery case 2. The top cover 6 is composed of two parts: the lead-out end and the bus part, the pole group and the bus part Are connected to each other to function as confluence and conduction. The lead-out end plays a role of conduction and is also a channel for connecting the battery to the outside. The lead-out end of the top cover 6 contains a hollow channel and has a through hole to the outside; The core part is provided with a stainless steel lining part 3 with a hollow structure. There is also an insulating sleeve 1 between the pole group 4 and the lining part. There is a sealing ring 7 between the top cover 6 and the lining part 3 and the battery case 2. The shell is filled with electrolyte; the lining part 3 contains ...

Embodiment 2

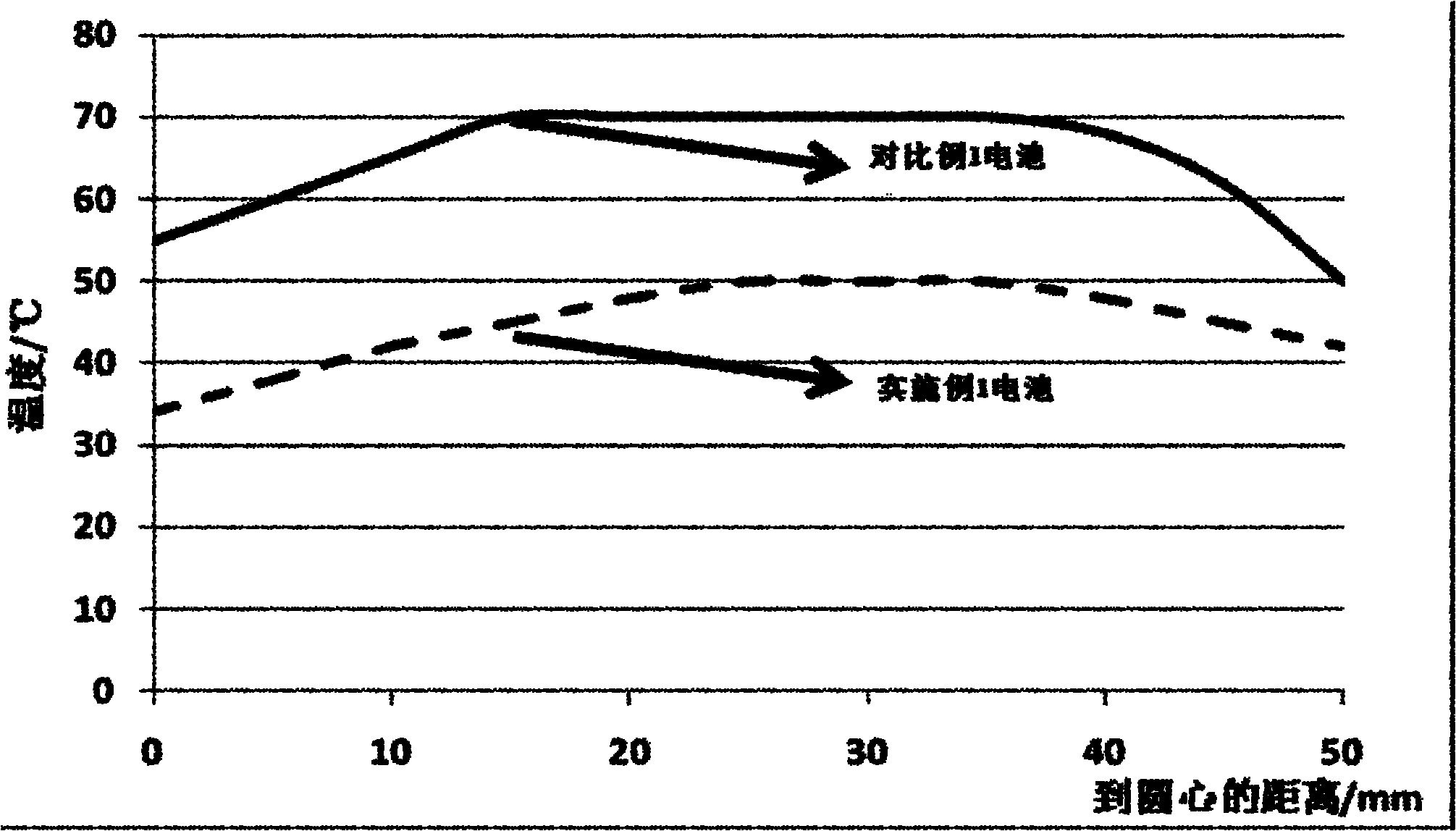

[0018] The two batteries of Example 1 and Comparative Example 1 were used to measure the internal temperature of the battery under the same conditions by implanting temperature sensors in different areas during the battery manufacturing process. After the battery was activated, a pulse charge and discharge test was performed. The test plan As follows: charge at 500A for 5S, put it aside for 5S, discharge at 500A for 5S, after 1000 cycles of continuous cycle, check the internal temperature of the battery, the result is as follows figure 2 Shown. The abscissa in the figure is the distance to the center of the circle, that is, 0-10 is the core part, and 50 is the battery surface. From figure 2 It can be seen that the maximum internal temperature of the battery in Example 1 is 50°C, while the battery in Comparative Example 1 is as high as 70°C; the internal temperature difference of the battery in Example 1 is 8°C, while the battery in Comparative Example 1 is as high as 20°C. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap