Multi-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

A multi-wire cutting machine and agitator technology, which is used in mixers with rotary stirring devices, mixers, liquid and solid mixing, etc. Flexible and reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

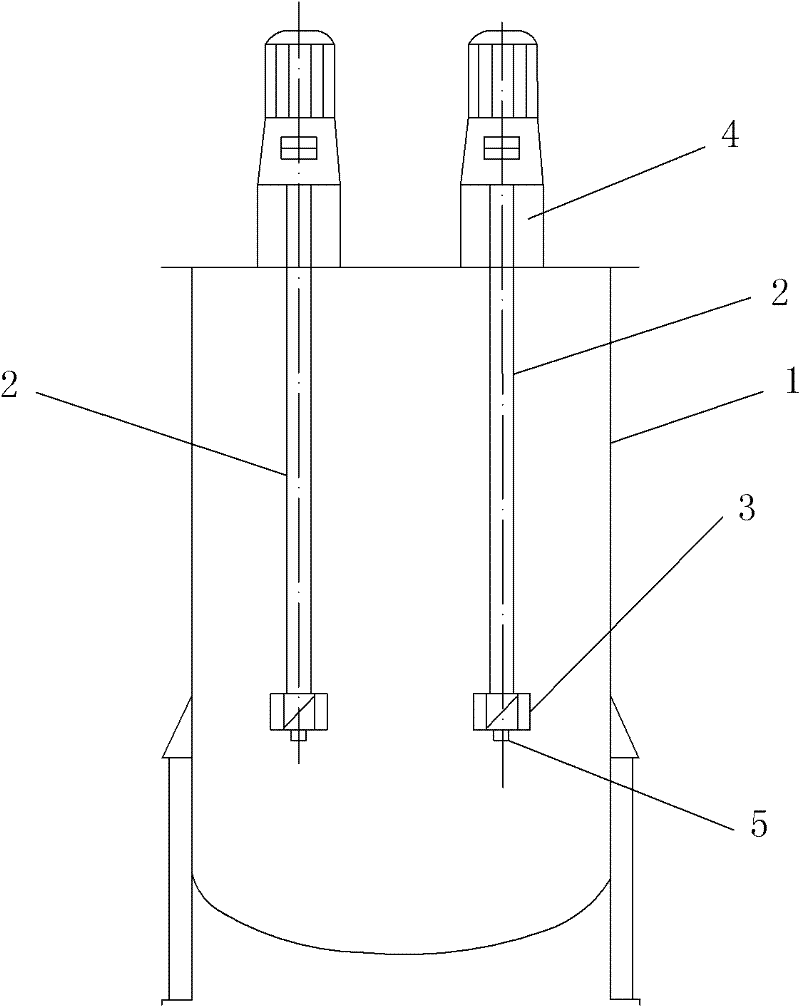

[0037] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a plurality of single-shaft stirring units arranged in the stirring tank body 1 along the circumferential direction, and the structures of the plurality of single-shaft stirring units are the same.

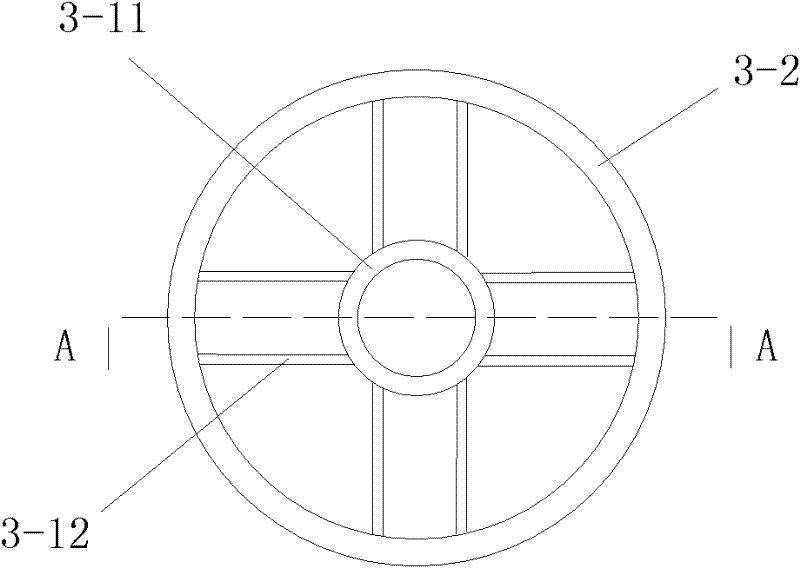

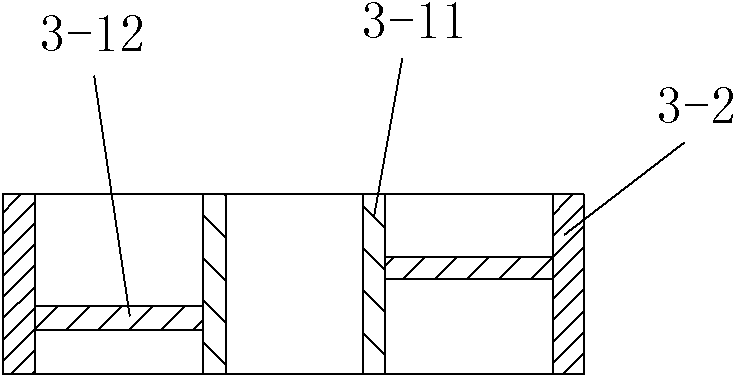

[0038] The single-shaft stirring unit includes a stirring shaft 2 installed in the stirring tank body 1 and arranged vertically, a stirring assembly 3 that continuously rotates with the stirring shaft 2 and uniformly stirs the materials in the stirring tank body 1, and A driving mechanism installed above the stirring shaft 2 and driving the stirring shaft 2 to continuously rotate, the driving mechanism is connected to the stirring shaft 2 through a transmission mechanism. The stirring assembly 3 is coaxially installed on the bottom end of the stirring shaft 2, and the stirring assembly 3 includes an impeller 3 that drives the material along the inner wall of the mixing tank body 1...

Embodiment 2

[0056] like Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that the number of the single-shaft stirring units is three, and the dimensions and installation heights of the three single-shaft stirring units are the same. In this embodiment, the structure, installation method and working principle of other parts are the same as those in Embodiment 1.

Embodiment 3

[0058] like Image 6 and Figure 7 As shown, in this embodiment, the difference from Example 1 is that: the number of the uniaxial stirring units is 4, and the number of the two uniaxial stirring units opposite to each other among the 4 uniaxial stirring units The dimensions and installation heights are the same, and the effective lengths of the stirring shafts 2 in two adjacent single-shaft stirring units are different, so the stirring assemblies 3 of the four single-shaft stirring units are not arranged at the same height. During actual processing and production, the dimensions and installation heights of the four single-shaft stirring units can also be adjusted to be consistent. In this embodiment, the structure, installation method and working principle of other parts are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com