Composite material mould

A composite material and composite material layer technology, used in the field of molds, can solve the problems of poor wear resistance and corrosion resistance, low mechanical strength, affecting the service life of the mold, and achieve low cost, long service life and improved product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

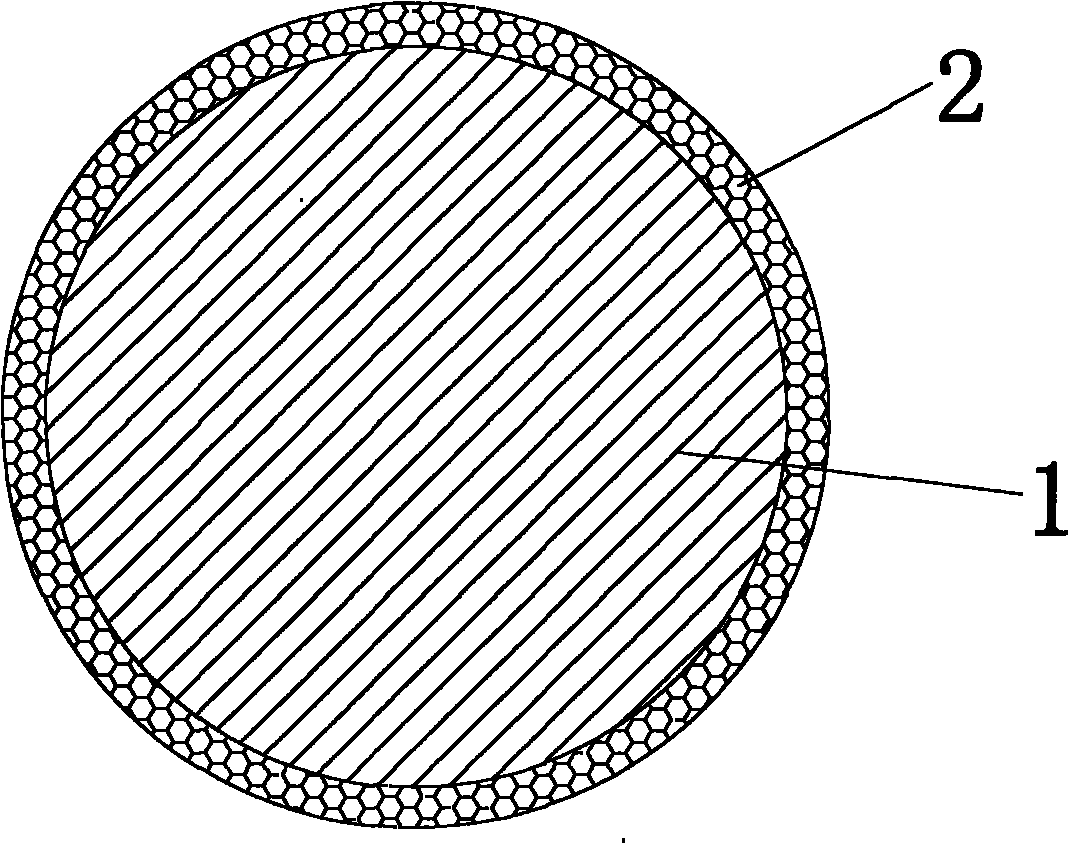

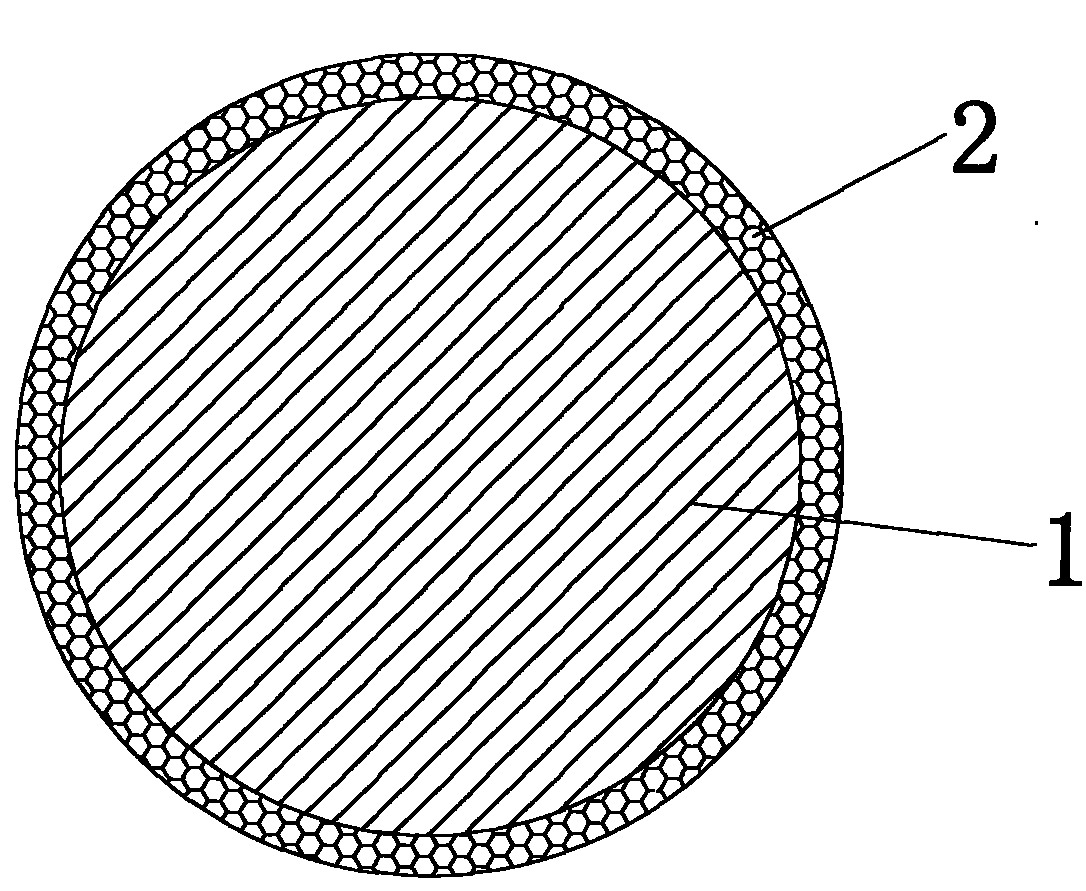

[0019] Prepare 17% epoxy resin, 50% acetone, 25.5% calcium carbonate powder, 4% by weight of resorcinol, 3.5% by weight of aminoethylpiperazine, mix epoxy resin and Dissolve resorcinol, then add calcium carbonate powder, add aminoethylpiperazine before use, after stirring evenly, a resin protection layer 2 is formed, and finally coated on the mold body 1.

Embodiment 2

[0021] Prepare 25% epoxy resin, 40% acetone, 30% calcium carbonate powder, 2.5% by weight of resorcinol, 2.5% by weight of aminoethylpiperazine, mix epoxy resin and Dissolve resorcinol, then add calcium carbonate powder, add aminoethylpiperazine before use, after stirring evenly, a resin protection layer 2 is formed, and finally wrapped on the mold body 1.

[0022] In the composite material mold provided by the present invention, the outer surface of the mold body has at least one layer of resin protective layer, which is coated or wrapped on the outer surface of the rod body, so that the surface of the mold is smoother, the product quality is obviously improved, and the mechanical strength of the mold is improved. Wear-resistant and corrosion-resistant performance, long service life, simple manufacturing method, low cost, can be widely used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap