Micro flocculation, membrane filtration and air flotation integrated reaction device and method for treating low-turbidity micro-polluted water by using same

A reaction device, a technology for micro-polluted water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the need for regular discharge of concentrated liquid, and improve impact resistance. , reducing the effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

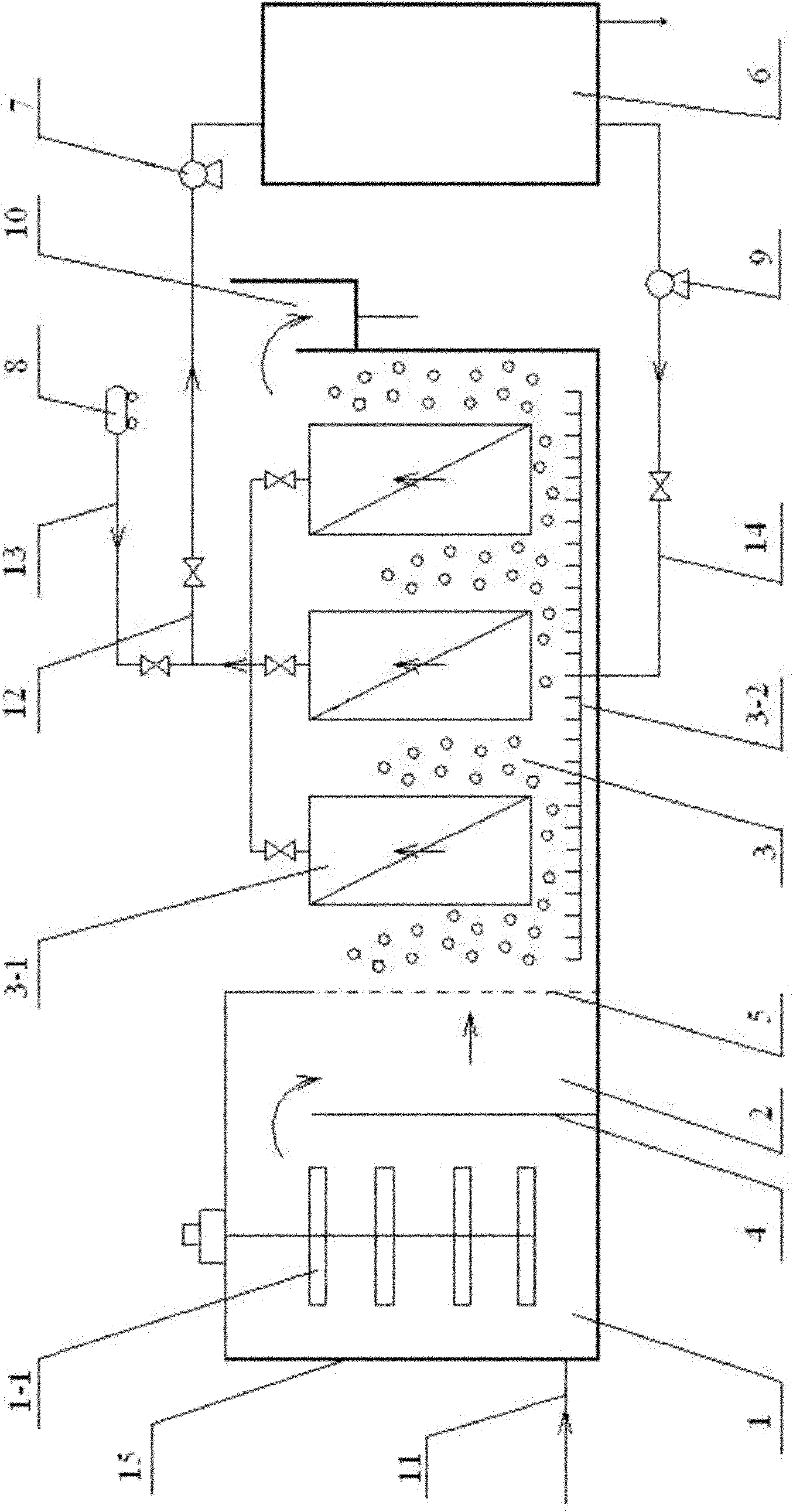

[0010] Specific implementation mode one: (see attached figure 1 ) The microflocculation, membrane filtration and air flotation integrated reaction device of this embodiment includes a flocculation, membrane filtration and air flotation integrated reaction tank 15, a water storage tank 6, a peristaltic pump 7, an air compressor 8, a dissolved air pump 9 and a flotation The slag tank 10, the integrated reaction tank of flocculation, membrane filtration and air flotation is composed of a mechanical micro-flocculation zone 1, a transition zone 2 and a membrane filtration-air flotation zone 3, and there is a weir between the mechanical micro-flocculation zone 1 and the transition zone 2 Plate 4 is separated, transition zone 2 and membrane filtration-air flotation zone 3 are separated by perforated flower wall 5, mechanical microflocculation zone 1 is equipped with mechanical stirring 1-1, and membrane filtration-air flotation zone 3 is equipped with ultrafiltration / microfiltration m...

specific Embodiment approach 2

[0013] Specific embodiment two: The method for processing low-turbidity and slightly polluted water with micro-flocculation, membrane filtration and air flotation integrated reaction device of this embodiment is carried out according to the following steps: low-turbidity and slightly-polluted water is passed into the flocculation, membrane The mechanical micro-flocculation zone 1 of the integrated filtration and air flotation reaction tank 15, after mechanical flocculation, overflows from the weir plate 4 into the transition zone 2, and then enters the membrane filtration-air flotation zone 3 through the perforated flower wall 5, and then enters the membrane filtration-air flotation zone 3 through the ultrafiltration Process under the condition that the microfiltration membrane module 3-1 and the dissolved air pump 9 work simultaneously, wherein the flux of the ultrafiltration / microfiltration membrane module 3-1 is 80L / (m 2 h)~120L / (m 2 h), the operating pressure is 0.7bar~1.0...

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment two is: mechanical microflocculation is to add polyaluminum chloride flocculant, the dosage of polyaluminum chloride flocculant is 30mg / L~45mg / L, hydraulic retention The time is 20 minutes to 25 minutes. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com