Method for producing microecological foliar fertilizer by utilizing probiotics and microalgae

A micro-ecological and foliar fertilizer technology, applied in the biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

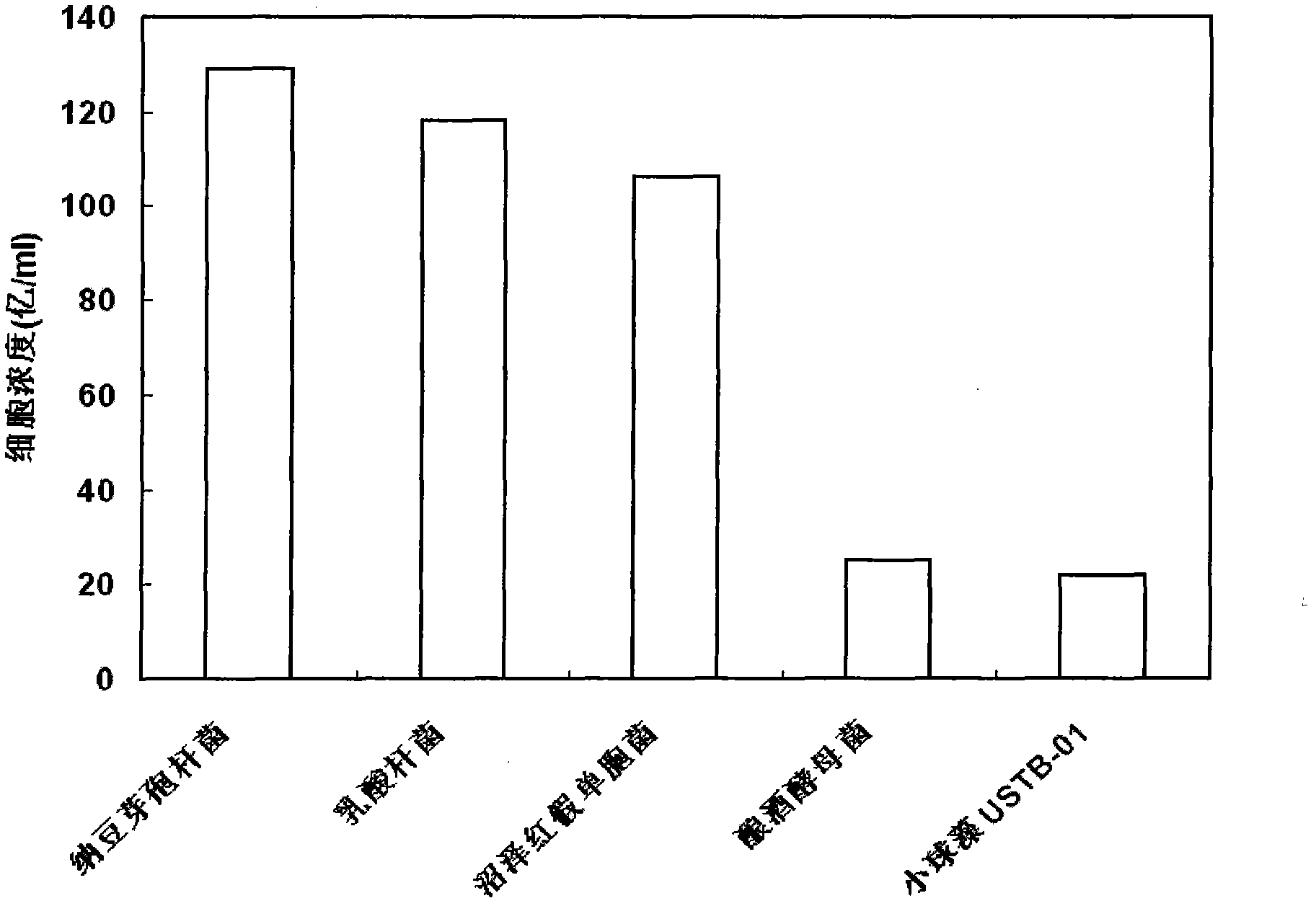

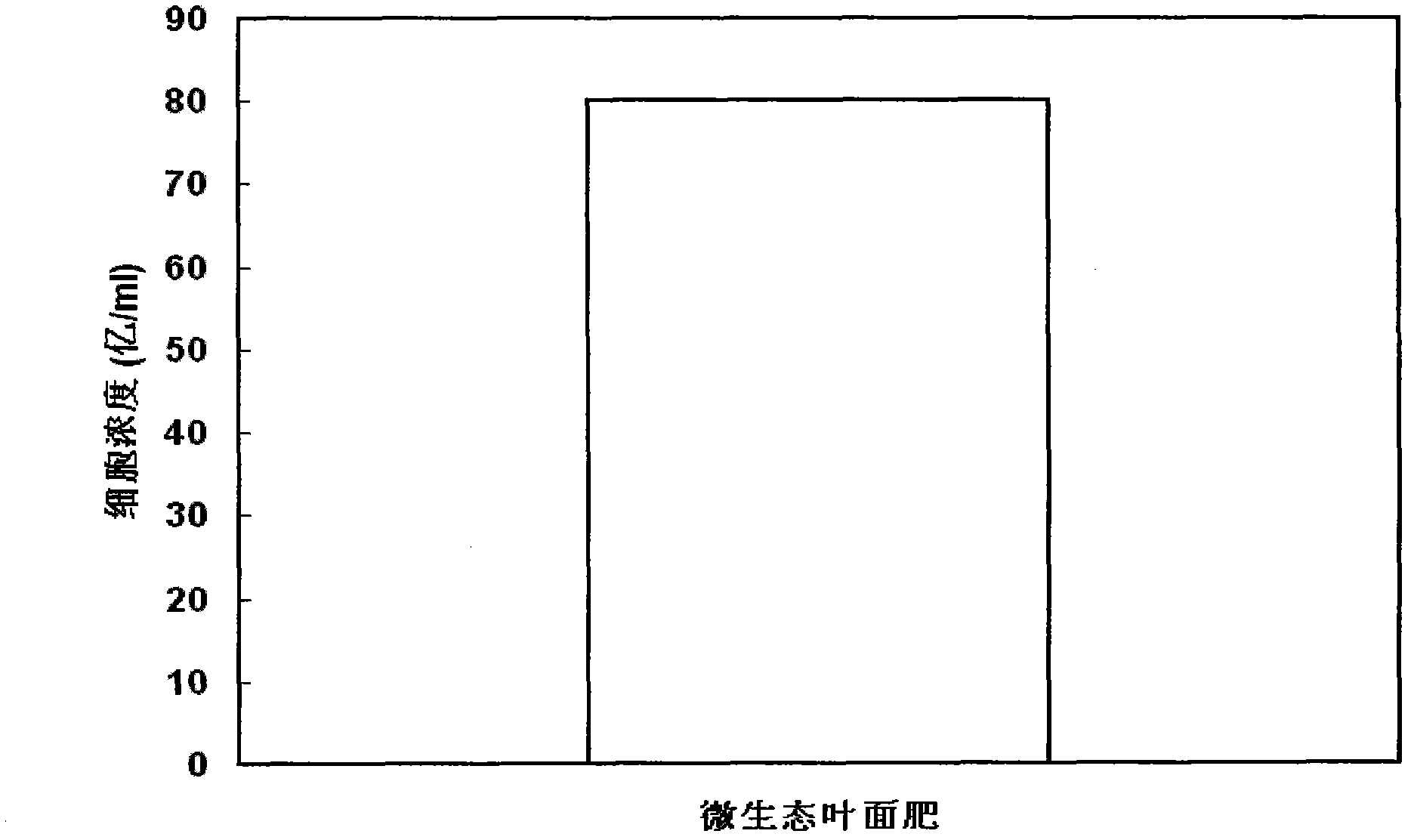

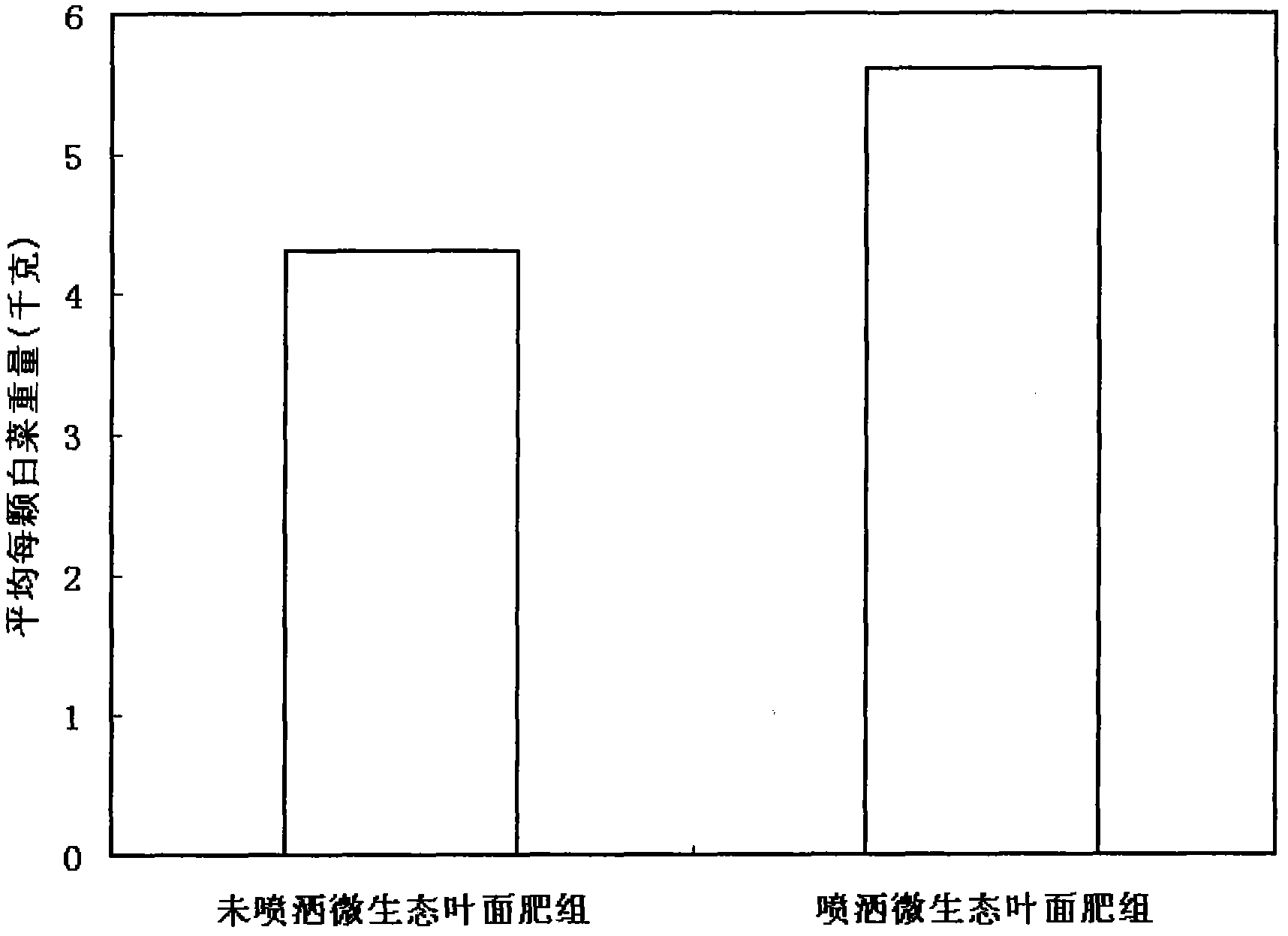

[0017] Firstly, the respective fermentation cultures obtained cell concentrations of 12.9 billion / ml Bacillus natto, 11.8 billion / ml Lactobacillus, 10.6 billion / ml Rhodopseudomonas palustris, 2.5 billion / ml Saccharomyces cerevisiae and 2.2 billion / ml small Liquid culture of coccus USTB-01, as attached figure 1 As shown, the cell concentration was 12.9 billion / ml Bacillus natto 100ml, 11.8 billion / ml Lactobacillus 100ml, 10.6 billion / ml Rhodopseudomonas palustris 100ml, 2.5 billion / ml Saccharomyces cerevisiae 100ml and 2.2 billion / ml ml Chlorella USTB-01100ml is mixed to obtain a micro-ecological foliar fertilizer with a total cell concentration of 8 billion / ml, as attached figure 2 shown. The micro-ecological foliar fertilizer produced by 4 kinds of probiotics and chlorella cultures was diluted 100 times with water, and sprayed evenly on the leaves of Chinese cabbage once every 10 days. After 60 days of growth of Chinese cabbage, 10 cabbages that were sprayed with and witho...

Embodiment 2

[0019] Firstly, the respective fermentation cultures obtained cell concentrations of 12 billion / ml Bacillus natto, 12.8 billion / ml Lactobacillus, 10.2 billion / ml Rhodopseudomonas palustris, 2.6 billion / ml Saccharomyces cerevisiae and 2.5 billion / ml small A total of 5 kinds of liquid cultures of the algae USTB-01 were mixed according to the proportions of 10%, 20%, 30%, 20% and 20% of the total volume percentage respectively, and a total cell concentration of 7.84 billion / ml was obtained. Ecological foliar fertilizer.

Embodiment 3

[0021] Firstly, the respective fermentation cultures obtained cell concentrations of 13 billion / ml Bacillus natto, 12 billion / ml Lactobacillus, 10.5 billion / ml Rhodopseudomonas palustris, 2.3 billion / ml Saccharomyces cerevisiae and 2.5 billion / ml small A total of 5 kinds of liquid cultures of the algae USTB-01 were mixed according to the proportions of 20%, 20%, 30%, 10% and 20% of the total volume percentage respectively, and a total cell concentration of 8.88 billion / ml was obtained. Ecological foliar fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com