Method for producing high-purity clomazone

A clomazone, high-purity technology, applied in the field of clomazone research, can solve the problems of high energy consumption, low degree of automation, small capacity of a single set of devices, etc., and achieve the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

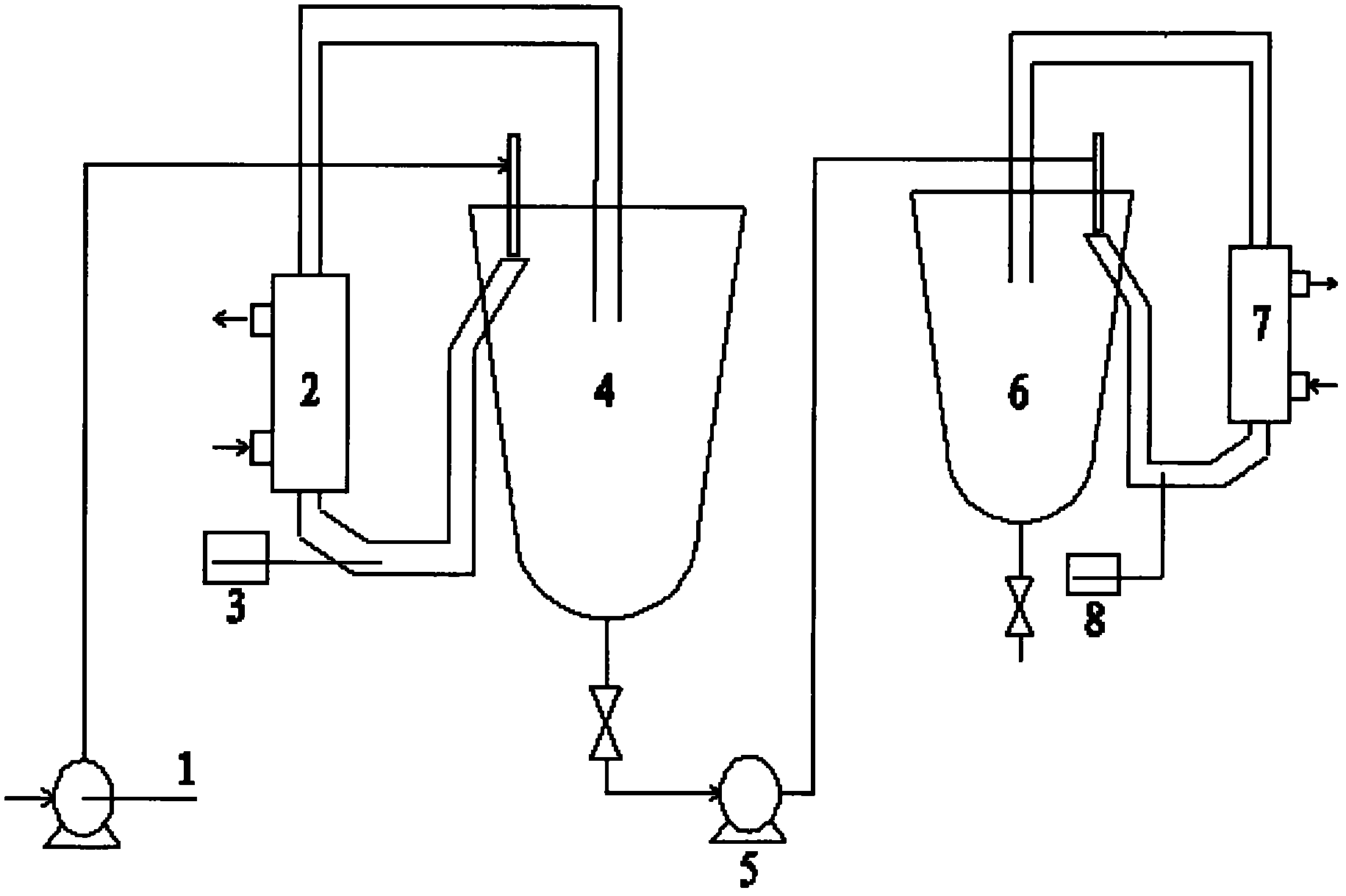

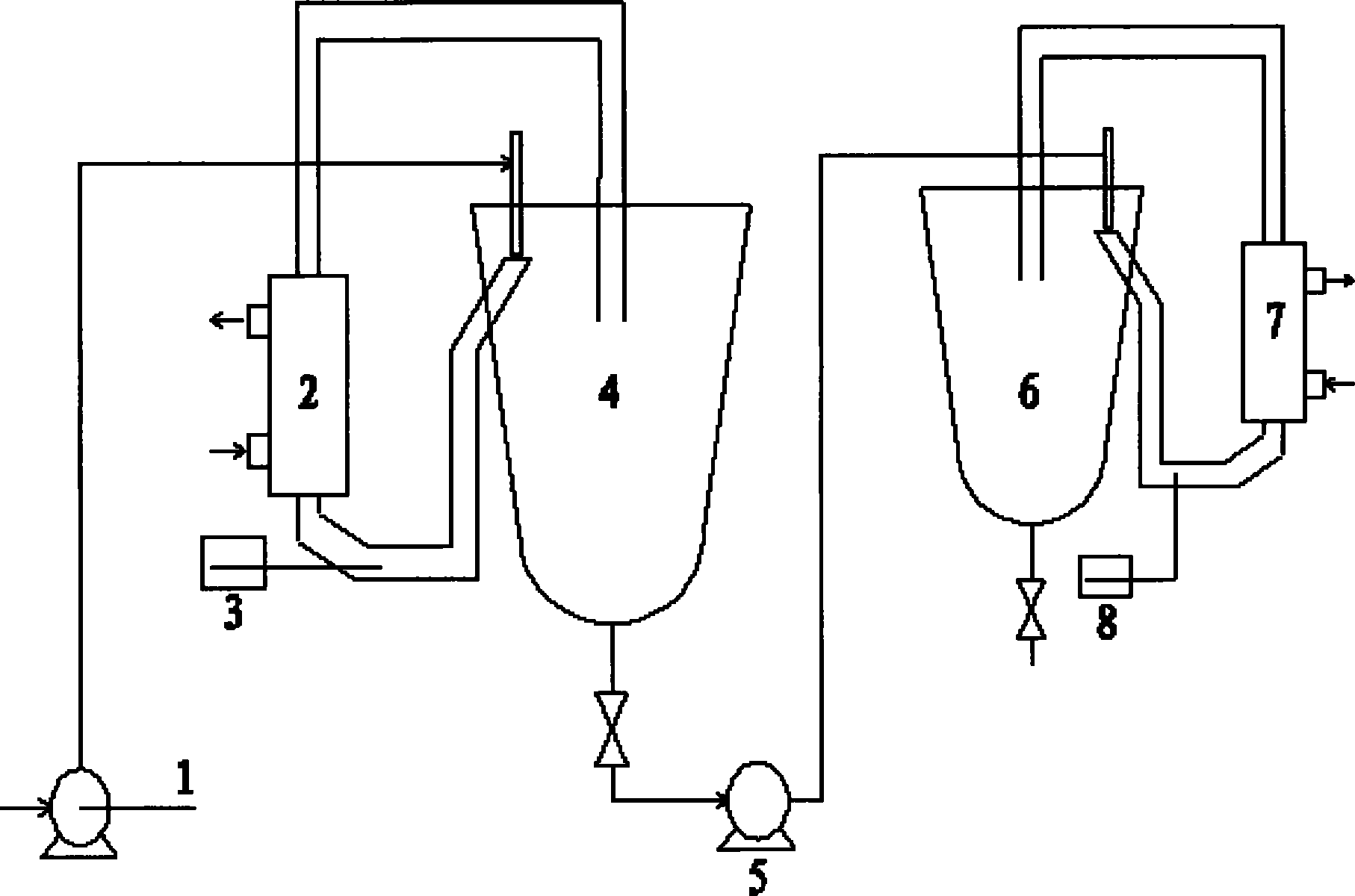

Image

Examples

Embodiment 1

[0018] Feed amount: 15m 3 / h, the feed temperature is 30°C, two volume-decreasing series crystallizers are used, the temperature of the first crystallizer is controlled at 15-18°C, cooled with frozen brine, and the average residence time of the material is 5h; the temperature of the second crystallizer is controlled at 18-20°C , using cooling water to cool, and the average residence time of the material is 5h. After the discharged feed liquid is filtered, the product with a content of 80% is obtained, and the content of the uncrystallized residual clomazone mother liquor in the mother liquor is 65%.

Embodiment 2

[0020] Feed amount: 15m 3 / h, the feed temperature is 30°C, three volume-decreasing series crystallizers are used, the temperature of the first crystallizer is controlled at 18-20°C, cooled with frozen brine, and the average residence time of the material is 5h; the temperature of the second crystallizer is controlled at 20-22°C , using cooling water to cool, and the average residence time of the material is 5h. The temperature of the third crystallizer is controlled at 22-25°C, cooled with cooling water, and the average residence time of materials is 5 hours.

[0021] After the discharged feed liquid is filtered, the product with a content of 97% is obtained, and the content of the uncrystallized residual clomazone mother liquor in the mother liquor is 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com