Two-step preparation method of large Al2O3-based crystal

A large-scale, two-step technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems that the two-step growth process has not been reported, and achieve short preparation cycle, short time-consuming, instrument simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

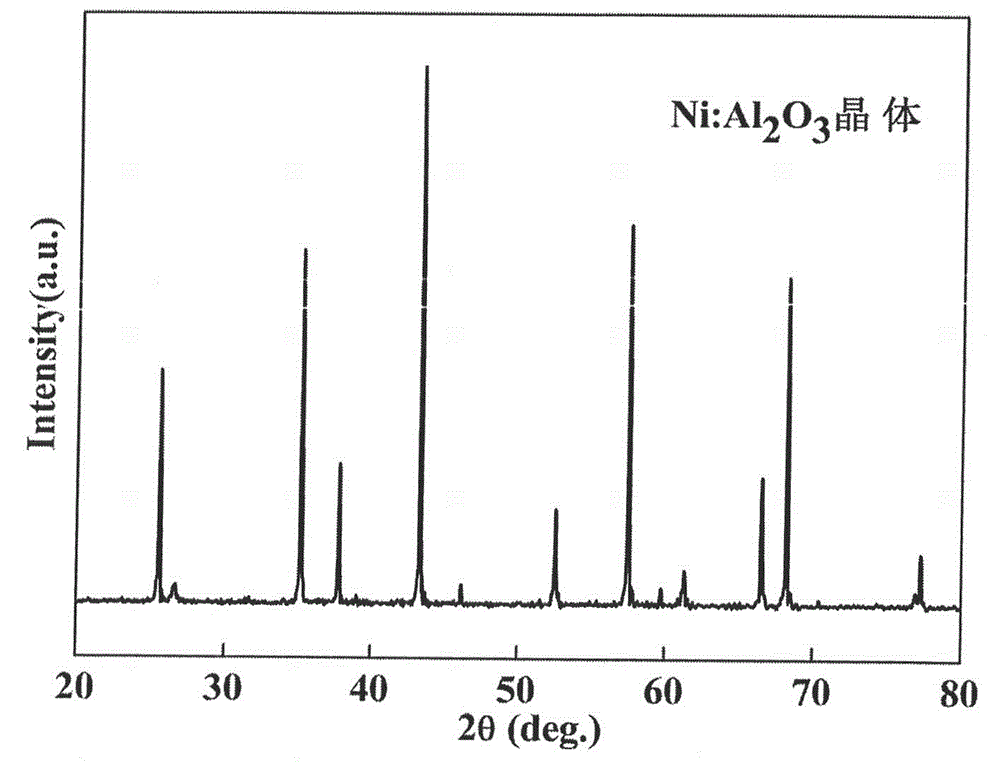

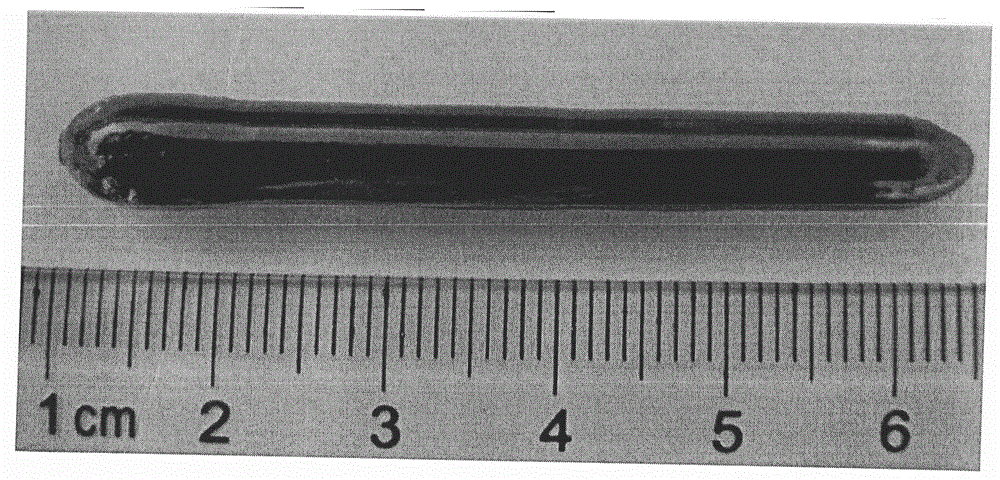

[0032] Embodiment 1: The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method crystal growth furnace produced by Crystal Systems Corporation of Japan, and what grows is Ni:Al doped with 1wt% NiO 2 o 3 crystals.

[0033] (1) Al 2 o 3 The powder and NiO powder are mixed according to the mass ratio of 99.0:1.0, placed in a ball mill tank for ball milling, dried and sieved.

[0034] (2) Put the powder obtained in (1) into a long rubber balloon for compaction, and place the rubber ball filled with the powder under isostatic pressure to make a green bar.

[0035] (3) Fix the biscuit rod obtained in (2) on the seed rod of the single crystal furnace (called the seed rod), and adjust the position of the seed rod so that the top of the seed rod is on the same horizontal line as the halogen lamp .

[0036] (4) In an air atmosphere, the halogen lamp of the single crystal furnace outputs a power of 2720W / h, the seed rod rotates ...

Embodiment 2

[0040] Embodiment 2: The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method crystal growth furnace produced by Crystal Systems Corporation of Japan, and what grows is Ni:Al doped with 1.5wt% NiO 2 o 3 crystals.

[0041] (1) Al 2 o 3 The powder and NiO powder are mixed according to the mass ratio of 98.5:1.5, placed in a ball mill tank for ball milling, dried, and sieved.

[0042] (2) Put the powder obtained in (1) into a long rubber balloon with a diameter of 10 and compact it, and place the rubber ball filled with the powder under isostatic pressure to make a green bar.

[0043] (3) Fix the biscuit rod obtained in (2) on the seed rod of the single crystal furnace (called the seed rod), and adjust the position of the seed rod so that the top of the seed rod is on the same horizontal line as the halogen lamp .

[0044] (4) In an air atmosphere, the halogen lamp of the single crystal furnace outputs a power of 2750W...

Embodiment 3

[0048] Embodiment 3: The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method crystal growth furnace produced by Crystal Systems Corporation of Japan, and what grows is Ni:Al doped with 2wt% NiO 2 o 3 crystals.

[0049] (1) Al 2 o 3 The powder and NiO powder are mixed according to the mass ratio of 98.0:2.0, placed in a ball mill tank for ball milling, dried and sieved.

[0050] (2) Put the powder obtained in (1) into a long rubber balloon for compaction, and place the rubber ball filled with the powder under isostatic pressure to make a green bar.

[0051] (3) Fix the biscuit rod obtained in (2) on the raw material rod of the single crystal furnace (called a material rod), and adjust the position of the material rod so that the end of the material rod is on the same horizontal line as the halogen lamp.

[0052] (4) In the air atmosphere, the halogen lamp of the single crystal furnace outputs a power of 2750W / h, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com