Plain cloth and preparation method thereof

A plain weave fabric and fabric technology are applied to the preparation of plain weave fabrics, the preparation method of plain weave fabrics and the field of plain weave fabrics, which can solve the problems of complex preparation process, high weaving cost, singleness and the like, and achieve the effects of wearing comfort and increasing pattern variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

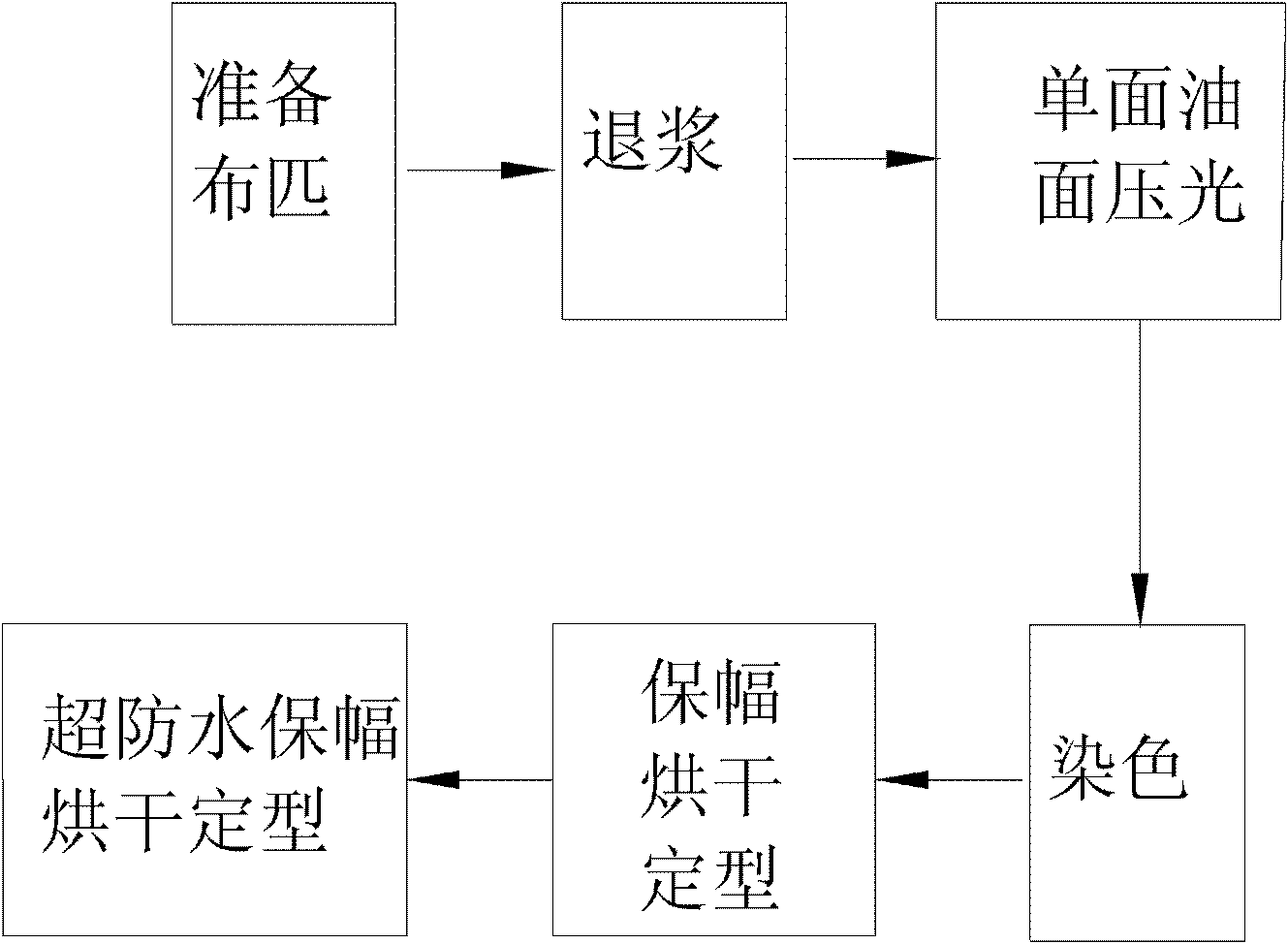

[0025] Choose nylon plain weave fabric, and carry out post-processing according to the following steps:

[0026] Desizing, desizing the prepared cloth, drying and coiling, the desizing speed is 20m / min;

[0027] Single-side oil calendering: the calendering temperature is 170°C, the speed is 15m / min, the pressure is 50T; the number of times is 4 times.

[0028] Take cloth and color it;

[0029] Put the acid dye into the batching container, and add an appropriate amount of 60-95°C water to stir until the dye is fully dissolved, and set aside;

[0030] Turn on the high temperature and high pressure overflow dyeing machine, adjust the dyeing machine process: nozzle diameter 70mm-90mm, gap 3.0-5.0mm, spray pressure 2.0-3.0kg, belt wheel speed 350-450m / min, belt wheel torque 40-50 %, by-pass is adjusted to "0", and the bath ratio (fabric weight: water) is 1:10-1:15. Pour water into the dye vat and raise the temperature to 30°C, add leveling agent, acid, and dye in turn, adjust th...

Embodiment 2

[0033] Choose nylon twill fabric, and carry out post-processing according to the following steps:

[0034] Desizing, desizing the prepared cloth, drying and coiling, the desizing speed is 30m / min;

[0035] Take cloth and color it;

[0036] Single-side oil calendering: the calendering temperature is 180°C, the speed is 25m / min, the pressure is 65T; the number of times is 3 times.

[0037] Pour water into the dye vat and raise the temperature to 25°C, add leveling agent, acid, and dye in turn, adjust the pH value of the dye to 4.5-5, raise the temperature to 65°C at a speed of 0.4°C / min, and then increase the temperature at a speed of 0.9°C / min Raise the temperature to 90°C, then raise the temperature to 110°C at a rate of 1.1°C / min, keep the temperature at 110°C for 45 minutes, and then cool down to 70°C at a rate of 110°C / min;

[0038]Dry the dyed cloth with a setting machine, and dry and set it at a speed of 60m / min at a temperature of 140°C.

[0039] Others are the same a...

Embodiment 3

[0041] Desizing, desizing the prepared cloth, drying and coiling, the desizing speed is 40m / min;

[0042] The calendering temperature is 200°C, the speed is 30m / min, the pressure is 80T; the number of times is 2 times.

[0043] Raise the temperature of the water to 20°C, add leveling agent, acid, and dye in sequence, adjust the pH value of the dye to 4.5-5, raise the temperature to 65°C at a speed of 0.6°C / min, and then raise the temperature to 90°C at a speed of 0.9°C / min ℃, then raise the temperature to 110°C at a rate of 1.1°C / min, keep the temperature at 110°C for 45 minutes, and then cool down to 70°C at a rate of 110°C / min;

[0044] Dry the dyed cloth with a sizing machine, and dry and set it at a speed of 40m / min at a temperature of 125°C. The setting temperature is 160°C-180°C, and the setting speed is 40-60m / min For ultra-waterproof width protection setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com