Cellular pneumatic driving wheel power machine

A power machine and driving wheel technology, applied in the field of grid-type pneumatic driving wheel power machine, can solve the problems of power consumption, waste of resources, lower utilization efficiency, etc., and achieve the effects of increasing output power, occupying less space, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

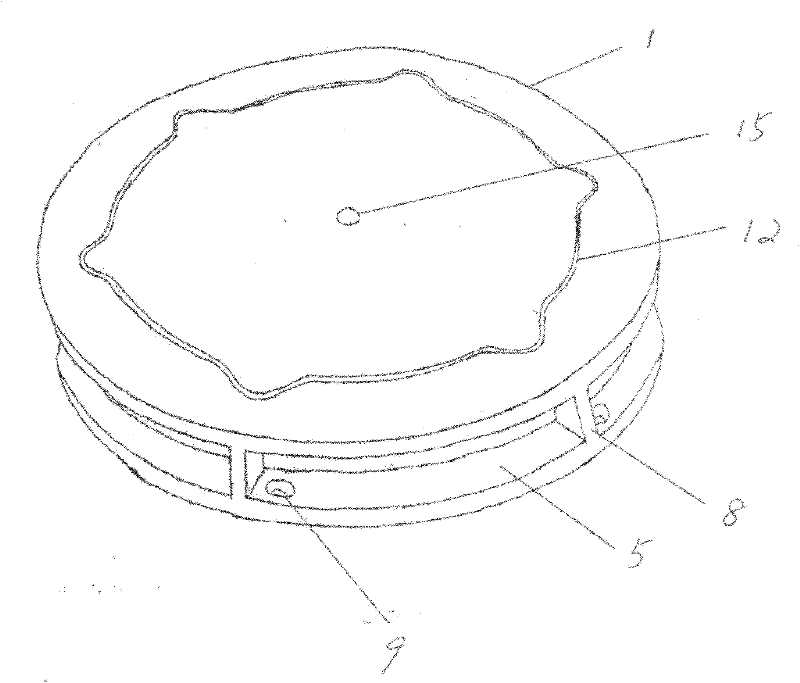

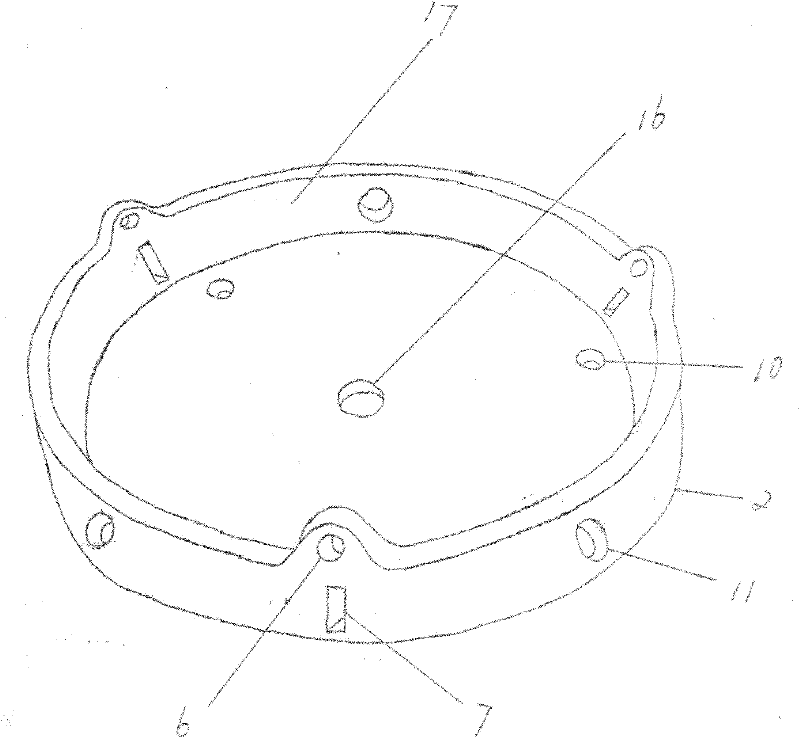

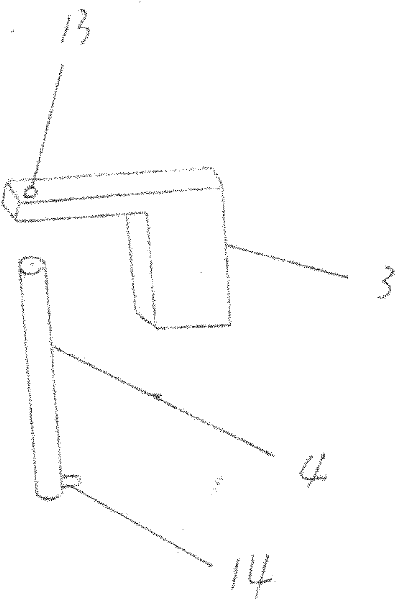

[0030] The invention uses the pressure air source to drive the driving unit to rotate, thereby driving the output shaft to rotate, and completing the power output. The number and size of drive units can be flexibly adjusted according to the required power. Each drive unit includes a rotating wheel 1, a base 2 and an air chamber sealed sliding partition 3, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown. The rotating wheel 1 is provided with a plurality of partitioned independent air grooves 5 separated by the air groove 8; an air inlet 9 is provided at one end of each partitioned independent air groove 5, and the air inlet 9 is opened in the rotating wheel The bottom surface of 1. At the same time, the upper bottom surface of the rotating wheel 1 is provided with an annular guide groove 12 centered on the center of the circle. The annular guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com