High-efficiency heat exchanger and method for processing heat exchanger membrane

A technology of heat exchanger and processing method, which is applied in the field of energy-saving and environment-friendly air treatment equipment, can solve the problems of breeding pathogenic bacteria and microorganisms, small heat transfer area, and low heat transfer efficiency, so as to increase the area, increase the passage path, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

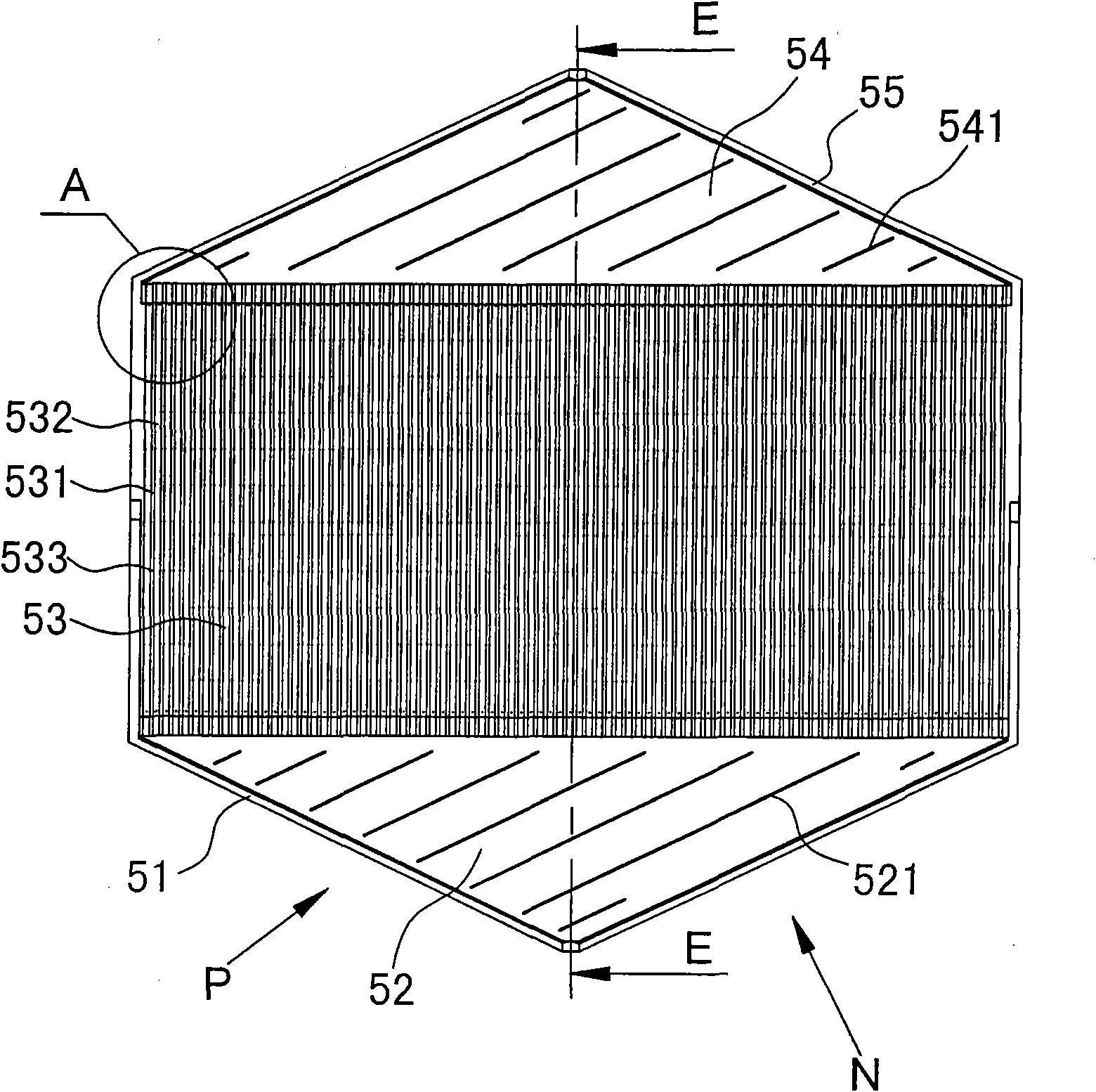

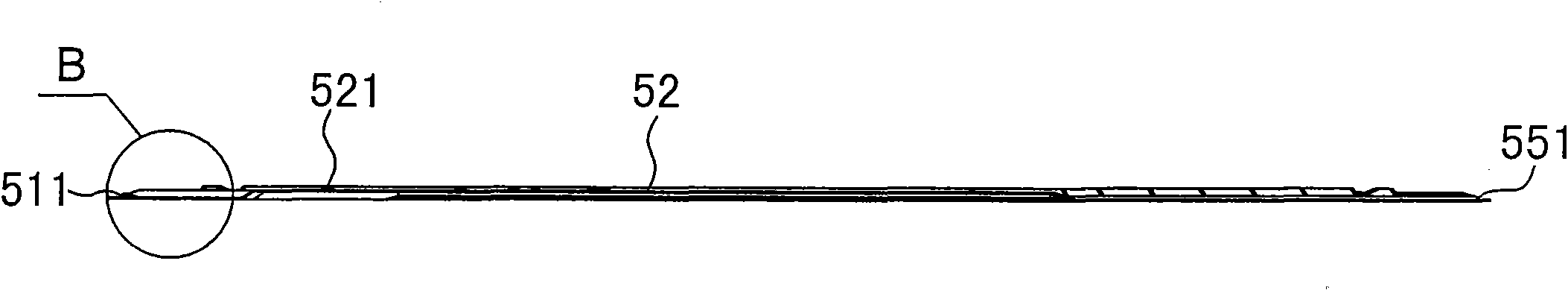

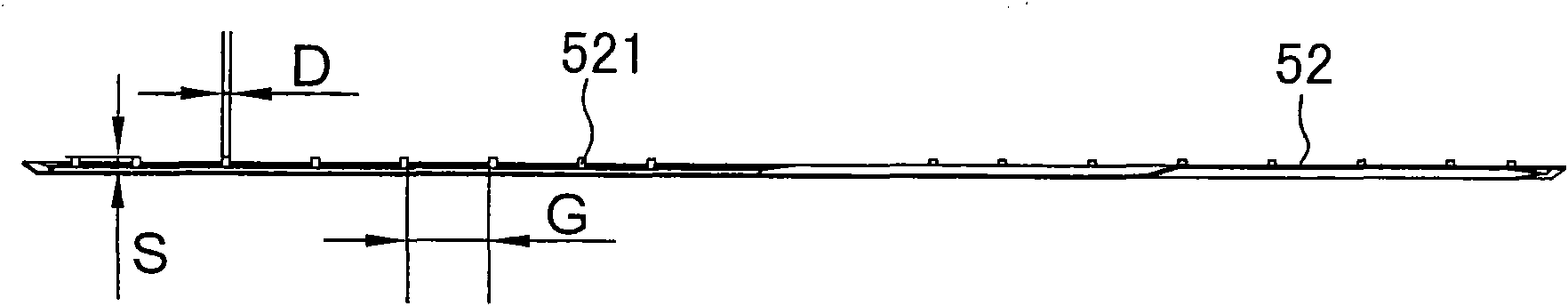

[0020] The present invention relates to high efficiency heat exchangers such as Figure 1-Figure 11 As shown, it is characterized in that it includes an upper chip 1 and a lower chip 2, and the upper and lower chips 1 and 2 are overlapped and combined. Each of them is equipped with a diversion air inlet 51, a diversion air inlet area 52, a core efficiency area 53, a diversion air outlet area 54 and a diversion air outlet 55, and the diversion air inlet 51 and the diversion air outlet 55 are arc surfaces The inlet and outlet 511, 551, the diversion air inlet area 52 and the diversion air outlet area 54 are made with induced air grids 521, 541, and the core efficiency area 53 is made with convex ridges 532, concave valleys 531 and micro Convex point 533, the flow direction of the diversion air inlet area and the diversion air outlet area intersect, and the diversion air inlet area, the core efficiency area and the diversion air outlet area form a "zigzag" air duct, which is inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Horizontal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com