Method for forming self-aligned contact hole by taking undoped silicon oxide as polycrystalline silicon cap layer

A self-aligned contact hole, polysilicon layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems that are not conducive to the realization of double gate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

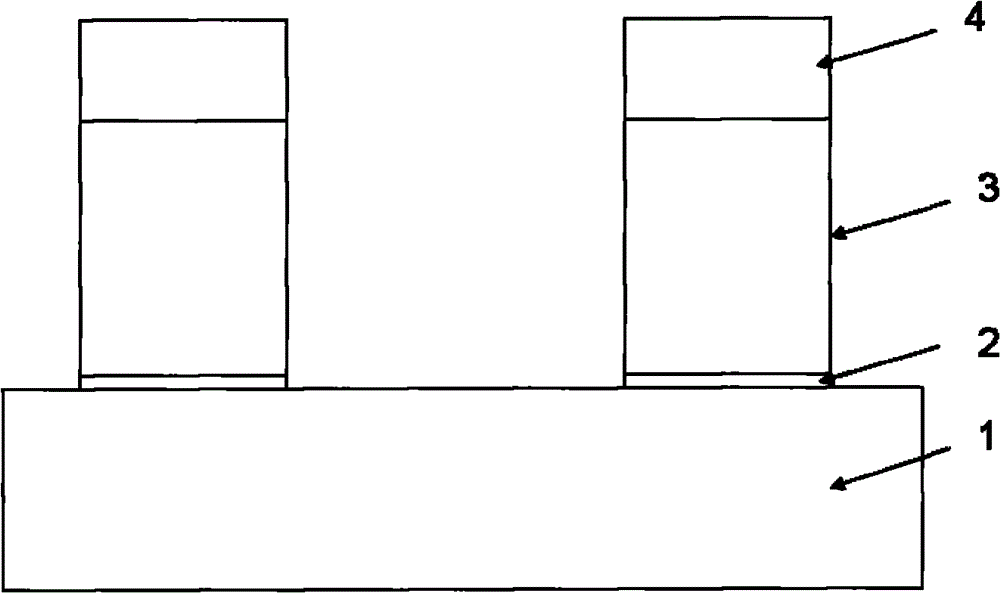

[0024] The invention provides a process method for making a self-aligned contact hole by using non-doped silicon oxide as a polysilicon cap layer. The PMD layer is made of phosphosilicate glass (PSG). In the contact hole etching, the self-alignment process is realized by controlling the high etching selectivity of the phosphosilicate glass and non-doped silicon oxide. On the other hand, due to the weak blocking ability of silicon oxide impurities, self-aligned polysilicon doping can be realized at the same time of source-drain implantation, thereby realizing a self-aligned double-gate process.

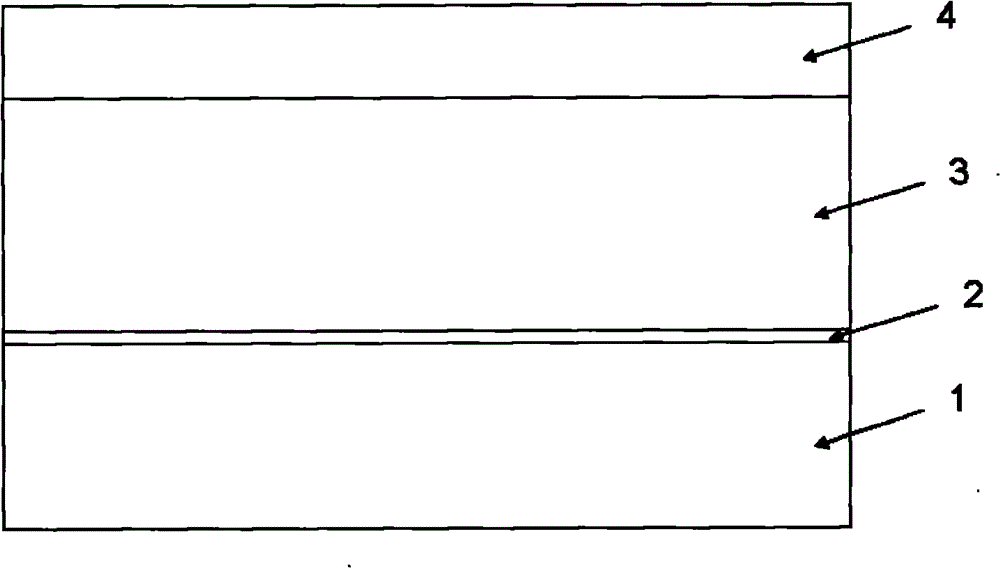

[0025] Main technological process of the present invention comprises the steps:

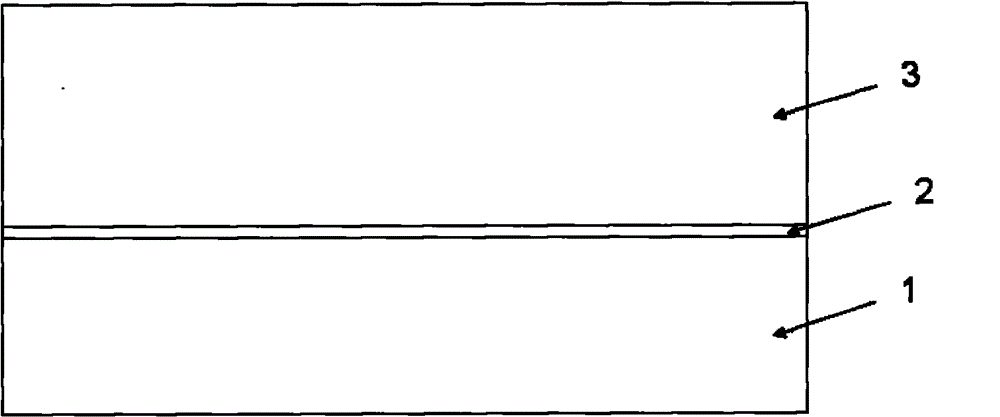

[0026] The first step, polysilicon deposition. Such as figure 1 As shown, according to the conventional process, the gate oxide layer 2 is first deposited on the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com