Diode pumping slab fixed laser

A solid-state laser and diode technology, applied in semiconductor lasers, lasers, semiconductor laser excitation devices, etc., can solve the problems of pump surface pollution, complex device structure, reduced device efficiency and lifespan, etc., and achieves low and high sealing requirements. Laser output, the effect of reducing the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

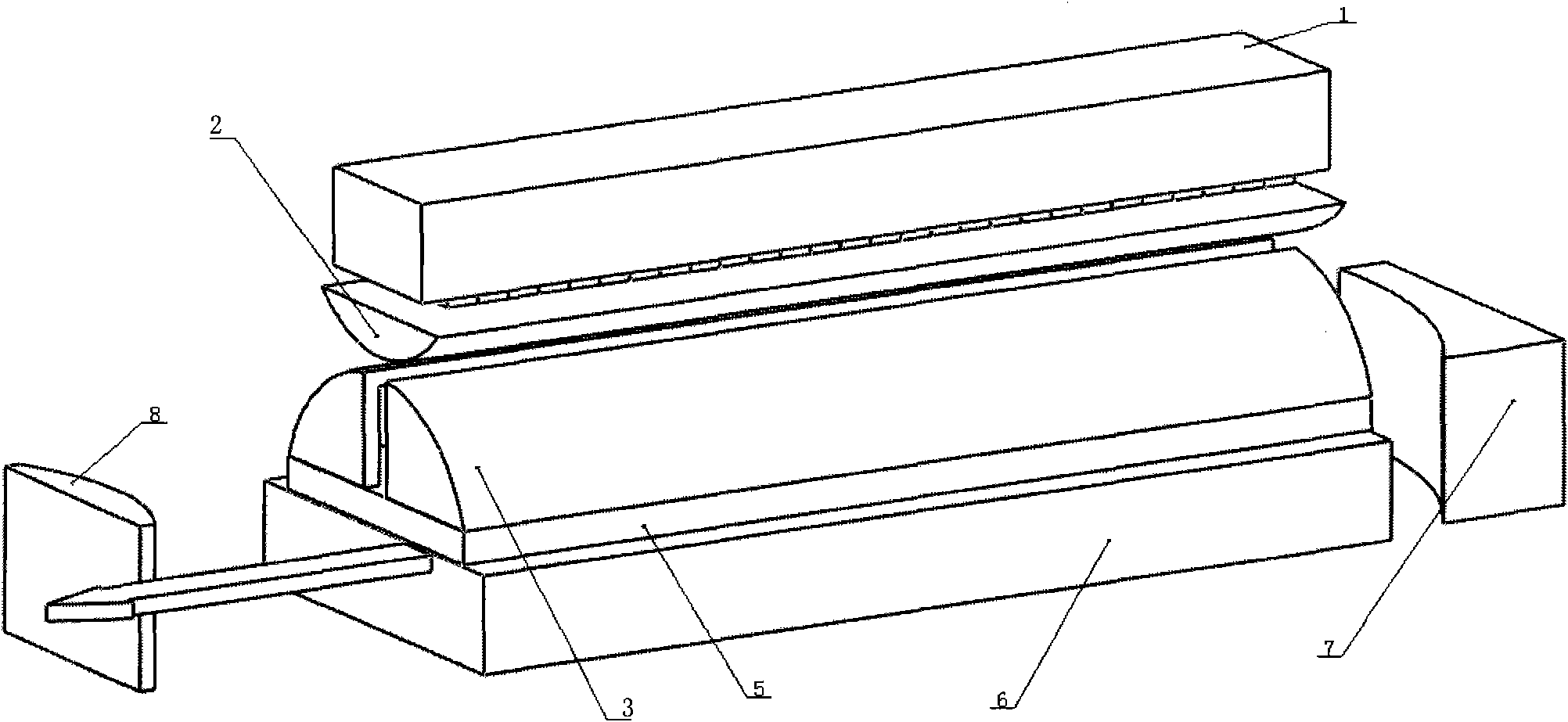

[0030] refer to figure 1 As shown in FIG. 4 , the diode-pumped slab solid-state laser includes a gain block, an input mirror 7 and an output mirror 8 . The gain module includes a diode array 1 composed of multiple laser diodes, a focusing mirror 2 , a condenser cover 3 , a slab-shaped gain medium 5 and a heat sink 6 . A set of opposite side surfaces of the slab-shaped gain medium 5 are polished and coated with an anti-reflection coating for the oscillating laser or the amplified light, serving as a light-transmitting surface for the laser or the amplified light. The lower surface of the slat-shaped gain medium 5 is gold-plated and sealed with the heat sink 6. The condenser cover 3 is placed on the upper surface of the slat-shaped gain medium 5, as shown in FIG. The pump light enters the gain medium again after being reflected by the condenser, which improves the utilization rate of the pump light and prevents the laser diode from being damaged due to the unabsorbed pump light...

Embodiment 2

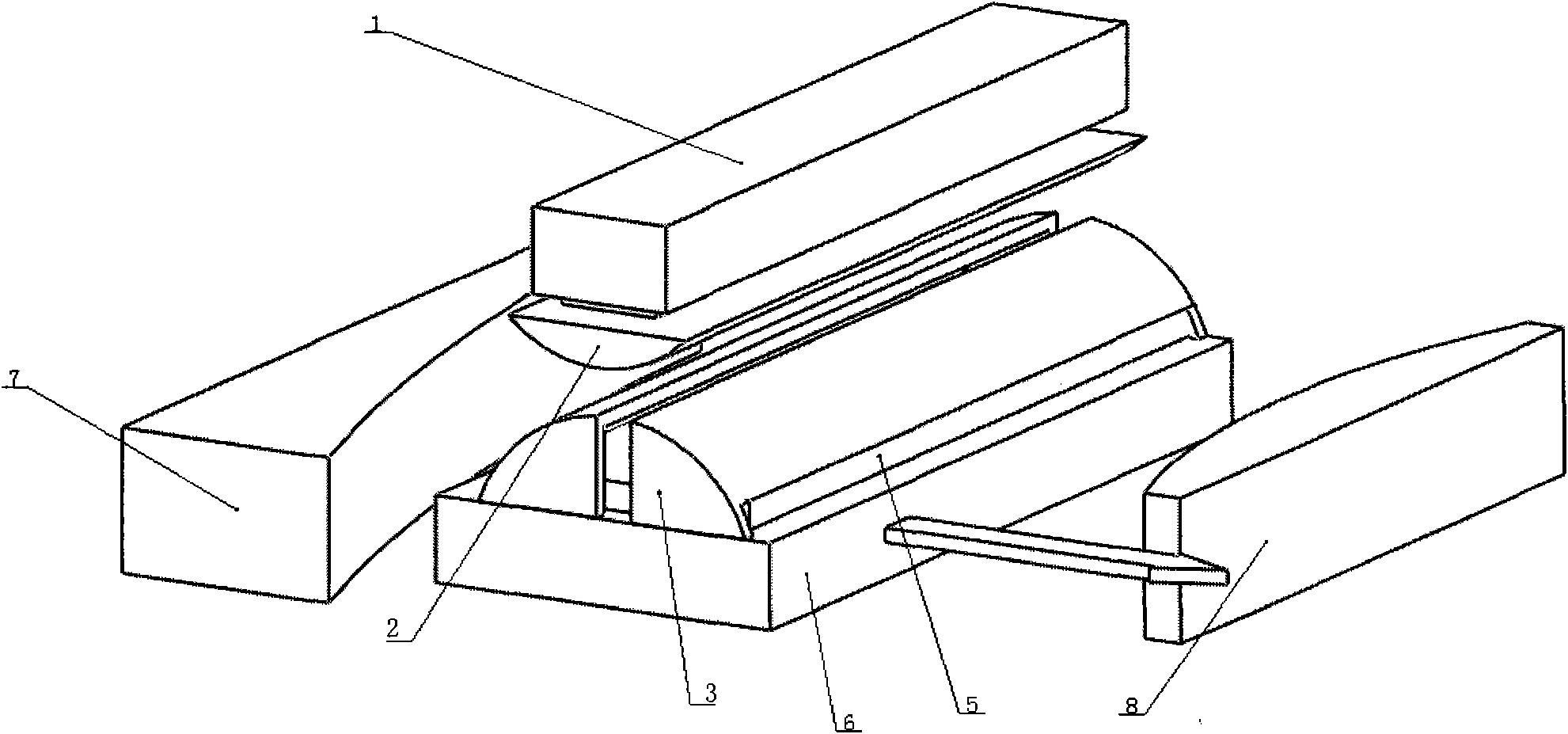

[0033] refer to figure 2 , the connection relationship of other structures is the same as in Embodiment 1, the condenser cover 3 is covered outside the slab-shaped gain medium 5 and placed on the heat sink 6, and the slab-shaped gain medium 5 at the lower end of the condenser cover 3 is coated with an anti-reflection film The position processing has a light outlet.

Embodiment 3

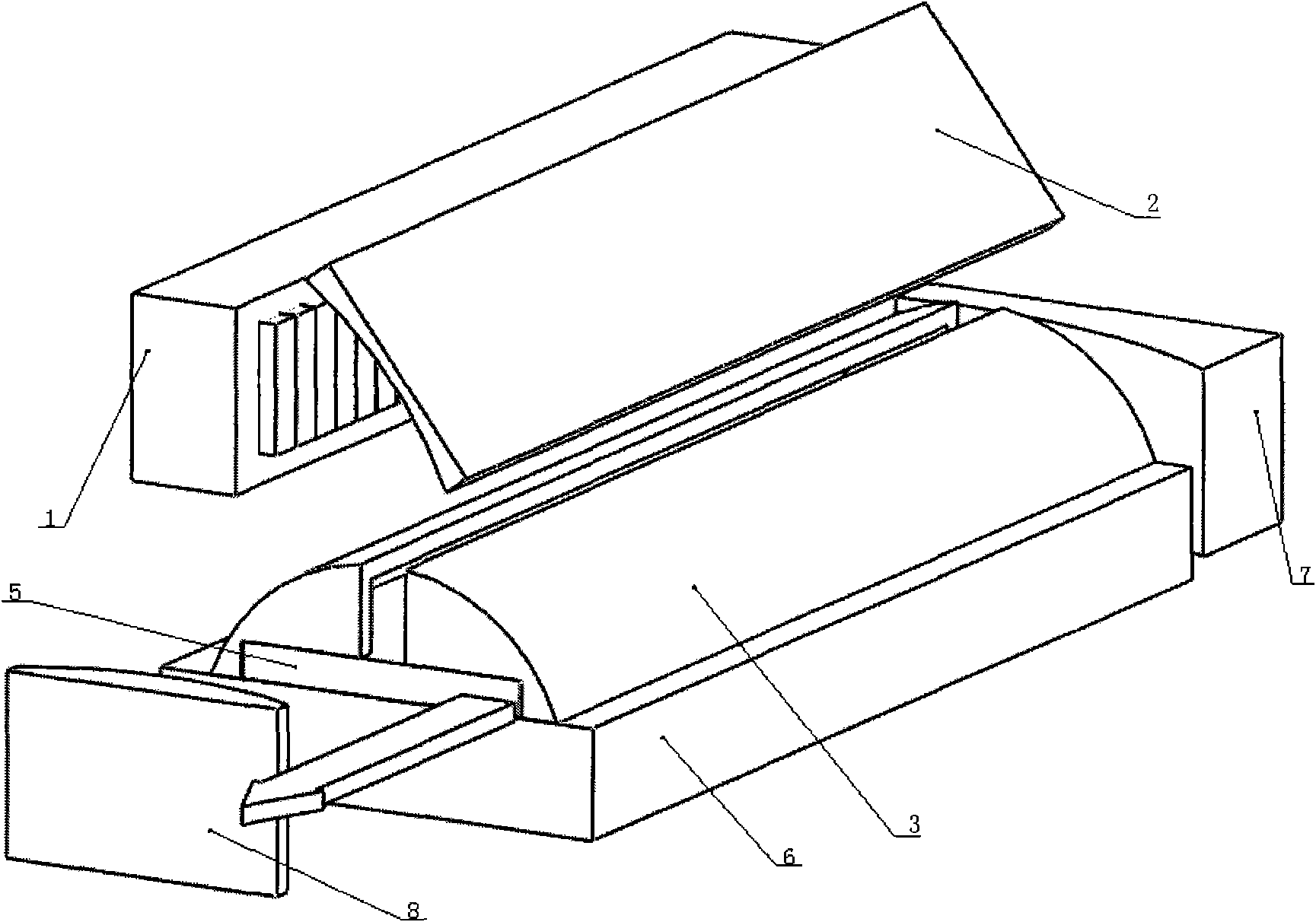

[0035] As shown in reference 3, the connection relationship of other structures is the same as that in Embodiment 1, and the focusing mirror 2 is a concave cylindrical reflector; A light outlet is processed at the position where the anti-reflection film is coated on the slat-shaped gain medium 5 at the lower end.

[0036] Taking the connection relationship of Embodiment 2 as an example, different slab-shaped gain media 5, input mirror 7 and output mirror 8 are selected to form a laser oscillator or laser amplifier of a diode-pumped slab solid-state laser to verify its oscillation or amplification. Effect.

[0037] The slab-shaped gain medium 5 adopts a laser crystal with a size of 50mm×200mm×1.5mm; the input mirror 7 adopts a concave spherical mirror with a radius of curvature of 600mm, and the structure is as follows Image 6 As shown; the output mirror 8 is a convex cylindrical mirror with a radius of curvature of -400mm; it forms a diode-pumped positive branch mixed cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com