Output current detecting circuit and transmission circuit

一种输出电流检测、电流检测的技术,应用在测量电流/电压、输出功率的转换装置、直流功率输入变换为直流功率输出等方向,能够解决功率损失大、功率消耗增多、输出电路占用面积芯片尺寸增大等问题,达到电源电压依存性低、温度依存性低、减小占用面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

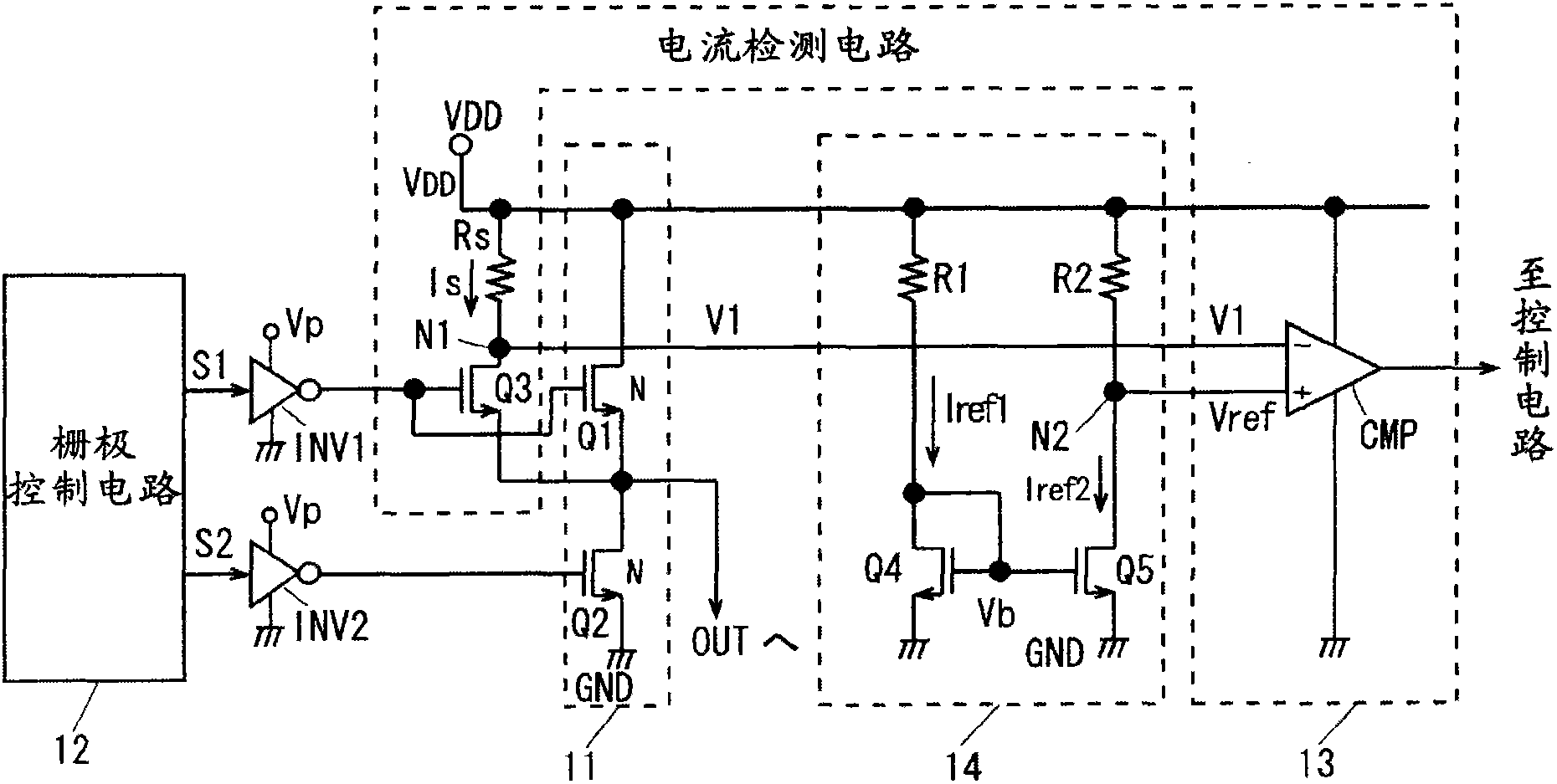

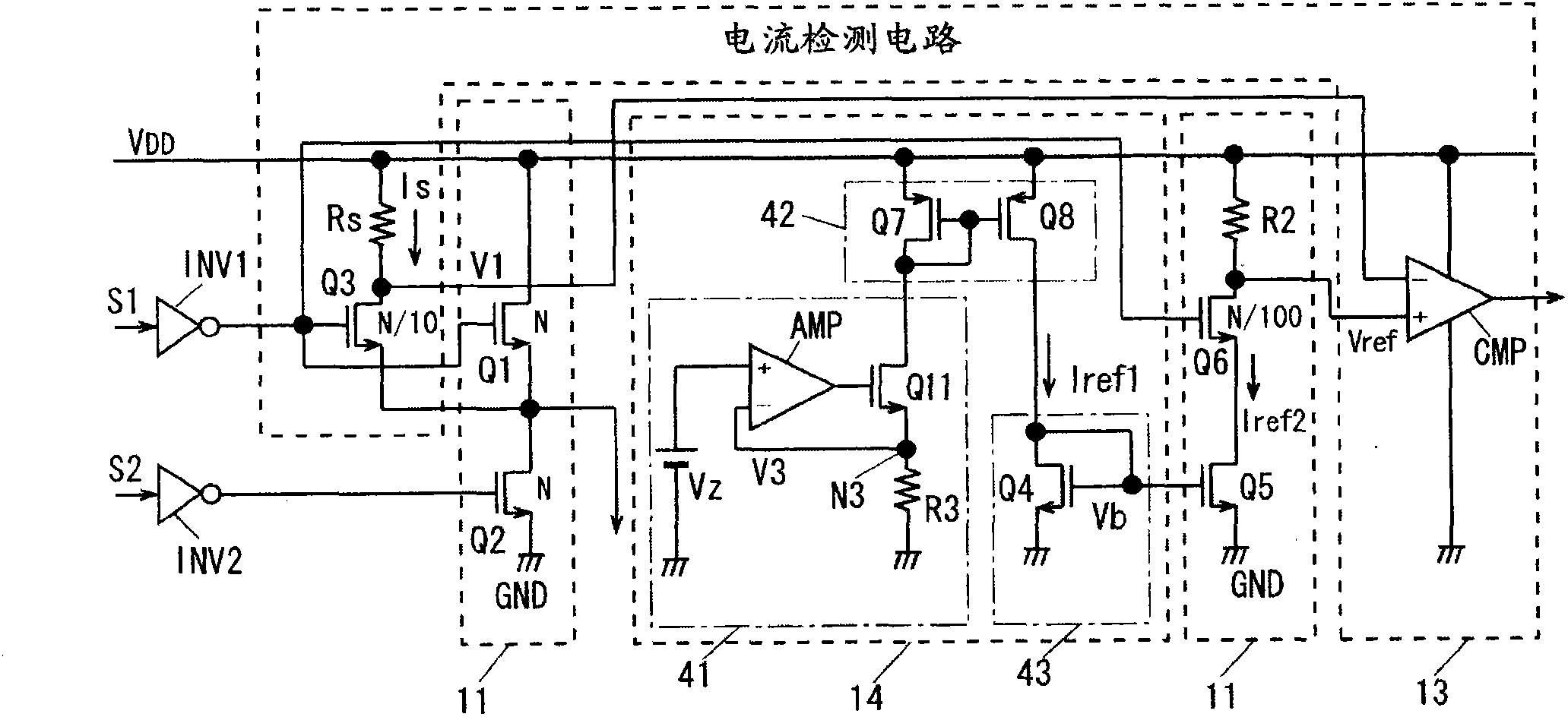

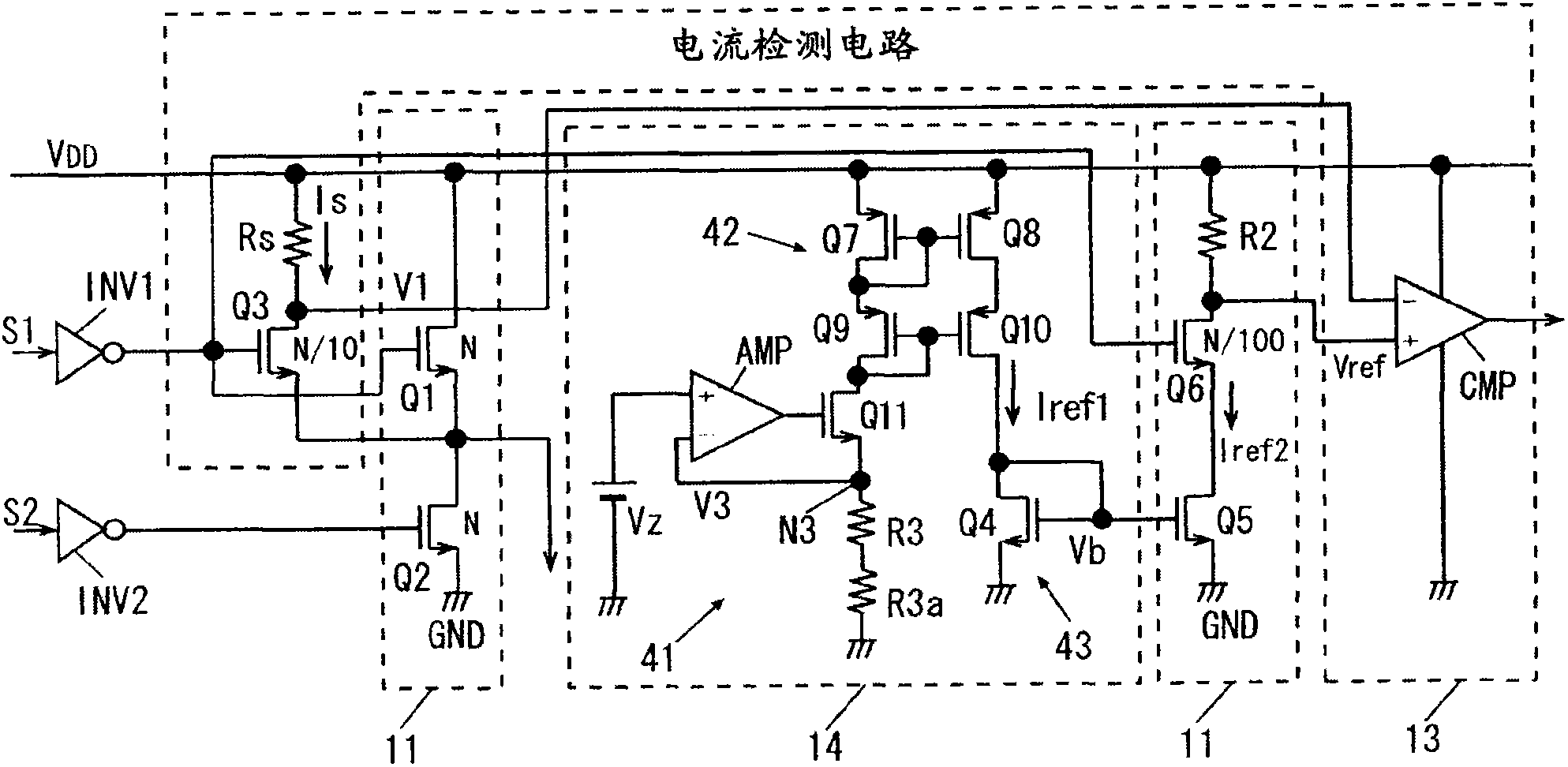

[0037] figure 1 12 shows a first embodiment of a transmission circuit built in an HBS driver / receiver IC that is implemented in a device constituting a system to which the HBS (Home Bus System) is applied and that is in charge of a communication function between devices. figure 1 The one circuit that drives one line in the twisted pair is shown in the figure. In the actual IC transmission circuit, in order to output signals with different polarities encoded by AMI, another figure 1 circuit like that.

[0038] The transmission circuit of the present embodiment includes output transistors Q1 and Q2 connected in series between the power supply voltage terminal VDD and the ground potential point GND as a push-pull type output circuit that outputs an AMI-encoded data signal by driving a transmission line. The output drive circuit 11; the gate control circuit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com