Structural foam and manufacture thereof

一种泡沫体、孔结构的技术,应用在薄料处理、运输和包装等方向,能够解决高剪切强度、没有公开各向异性泡沫生产等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

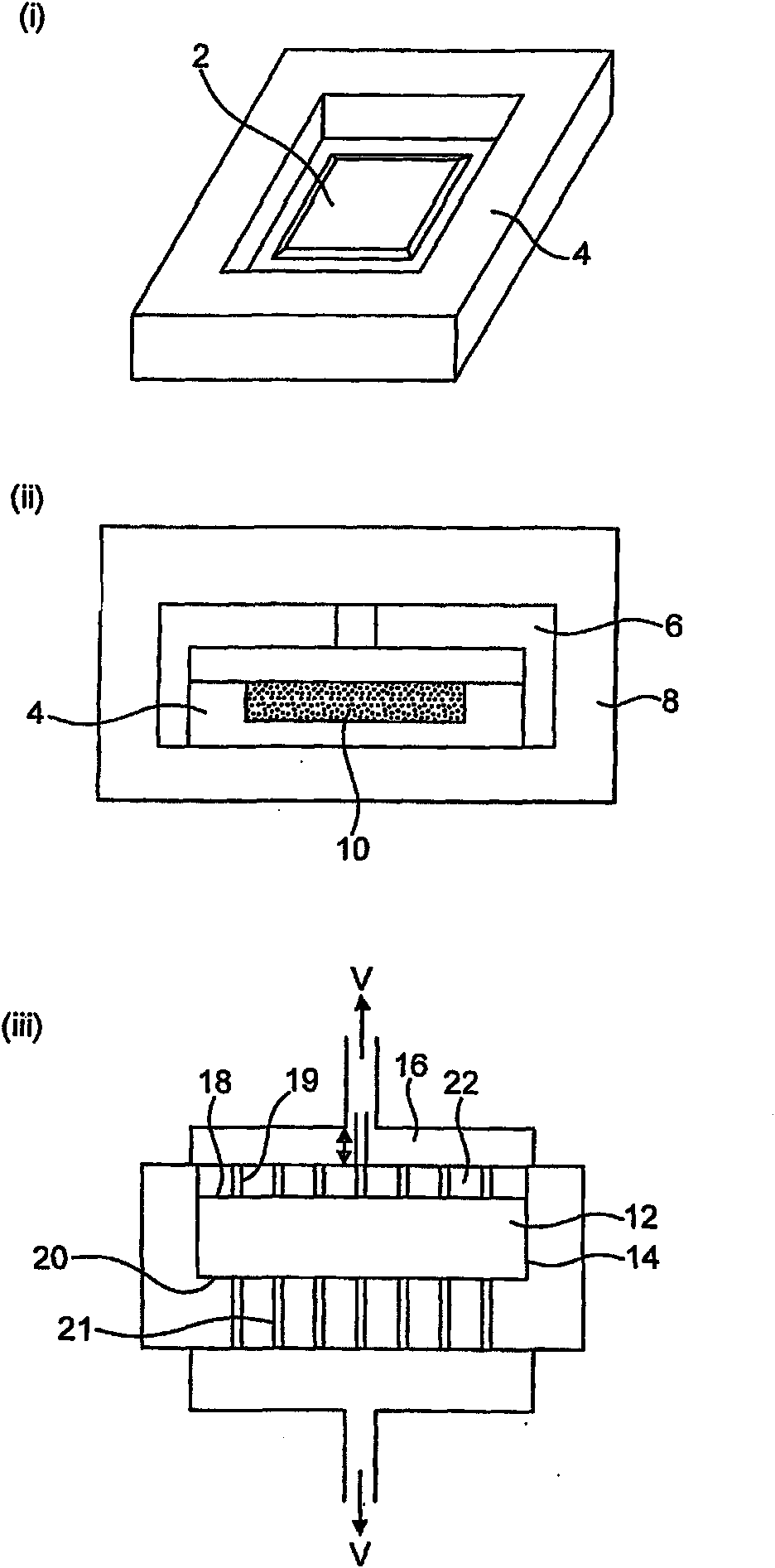

Embodiment 1

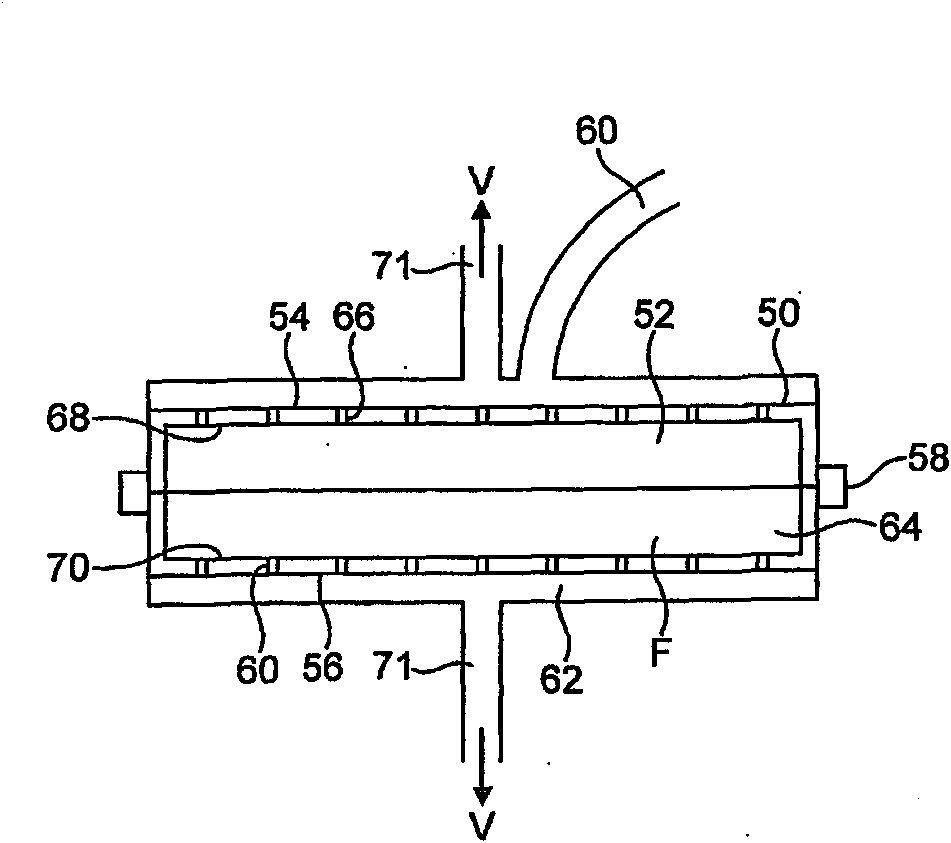

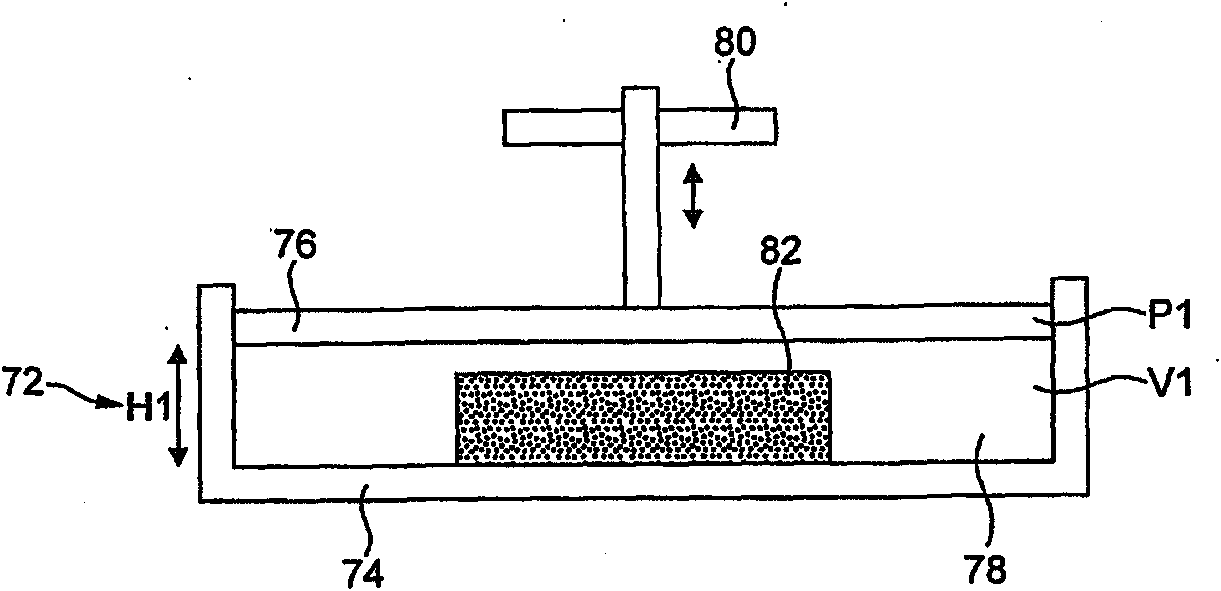

[0098] In this example, a foam stock was prepared of a styrene-acrylonitrile (SAN) polymer, similar to the polymer used to make the applicant's Corecell (registered trademark) structural foam. The billet also contained a blowing agent containing azobisisobutyronitrile (AZDN) and acetone. The blank is cut to a predetermined rectangular shape and size and placed in a mold which is placed in a hydraulic press, shaped and sized to determine the maximum horizontal width and length of the expanded foam formed from the blank in the mold size. In order to achieve the desired value of the anisotropy index, a confinement system is provided to prevent any growth in length and width of the billet sample as it is heated and expanded to form the expanded foam. These samples are placed in a hydraulic press at a given temperature for a period of time in order to achieve the desired expansion defined by the limits of the mold cavity.

[0099] In this embodiment, the mold does not limit the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com