Manufacturing method of biological tooth root bracket material

A technology of scaffold material and construction method, which is applied in dentistry, dental implantation, dental prosthesis, etc., can solve the problem of alveolar bone regeneration without corresponding discussion, the reconstruction of biological root scaffold materials, and the inability to design scaffold materials, etc. problem, to achieve the effect of easy to master the construction operation, solve the problem of inducing the microenvironment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

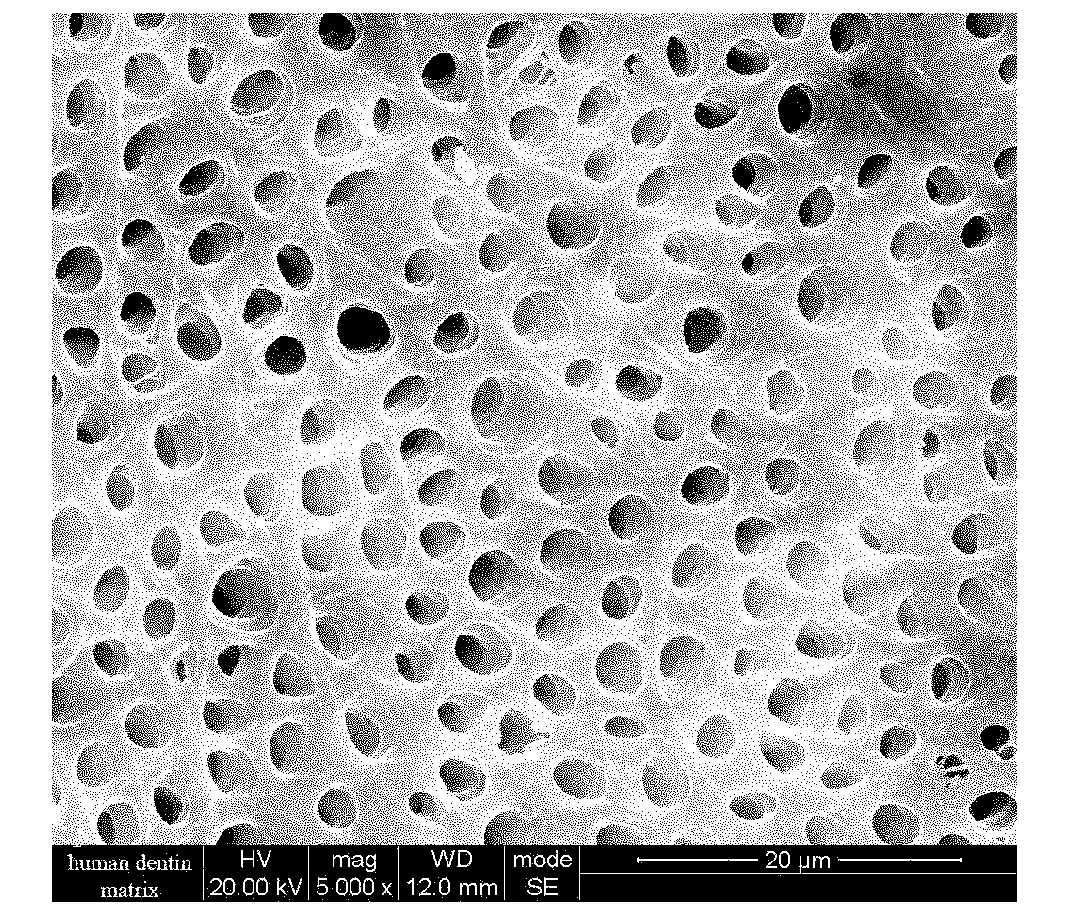

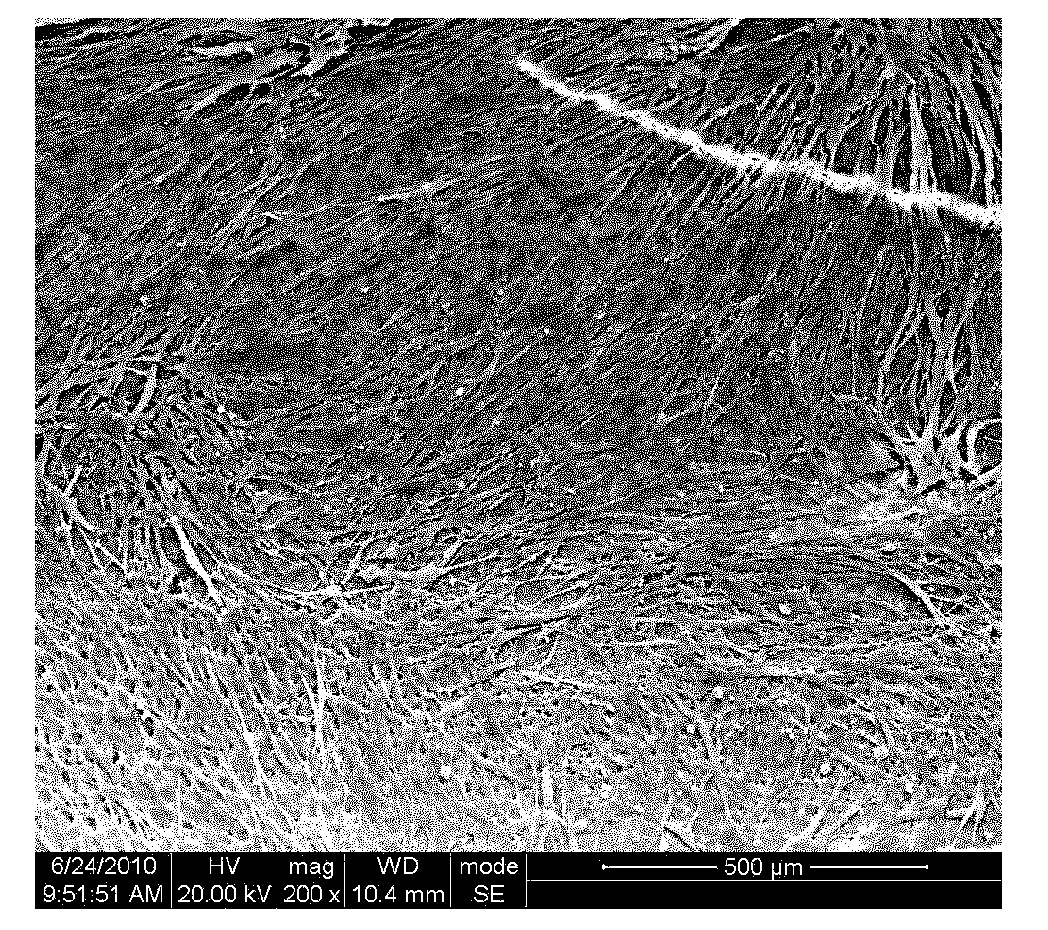

[0034] Embodiment 1, Preparation of human anterior tooth biological root scaffold materials and induced microenvironment:

[0035] The preparation method of the biological tooth root support material that the present embodiment enumerates comprises the following steps:

[0036] (1) Take four healthy front teeth, wash them three times with PBS solution, store them in culture bottles or other containers containing PBS, seal the bottles with parafilm and store them in a refrigerator at 4°C;

[0037] (2) Install corundum chips on a dental slow-speed turbine with a water spray device, adjust the speed to 3000 rpm, use corundum chips to grind off the crown of the tooth obtained in step (1), keep the root part and store it in a container containing In a PBS culture bottle or other vessel, seal the bottle with parafilm and store in a refrigerator at 4°C;

[0038] (3) Use a dental pulp extraction needle to completely extract the pulp tissue in the root of the tooth obtained in step ...

Embodiment 2

[0048] Embodiment 2, Preparation of human premolar biological root scaffold materials and induced microenvironment:

[0049] The preparation method of the biological tooth root support material that the present embodiment enumerates comprises the following steps:

[0050] (1) Take four premolars, wash them three times with PBS, store them in culture bottles or other containers containing PBS, seal the bottles with parafilm and store them in a refrigerator at 4°C.

[0051] (2) In the case of a water spray device, install emery chips on the slow-speed dental turbine, adjust the speed to 6500 rpm, use emery chips to remove the crown part of step (1), keep the root part and store it in a container containing In culture flasks or other vessels with PBS, seal the bottle with parafilm and store in a 4°C refrigerator.

[0052] (3) Use a dental pulp extraction needle to completely extract the pulp tissue in the root of the tooth obtained in step (2), and rinse the inside of the root...

Embodiment 3

[0061] Embodiment 3, Preparation of biological root scaffold materials and induced microenvironment for human molars (multi-rooted teeth):

[0062] The preparation method of the biological tooth root support material that the present embodiment enumerates comprises the following steps:

[0063] (1) Take four healthy molars, wash them three times with PBS solution, store them in culture bottles or other containers containing PBS, seal the bottles with parafilm and store them in a refrigerator at 4°C;

[0064] (2) Install corundum chips on a dental slow-speed turbine with a water spray device, adjust the speed to 4000 rpm, use corundum chips to grind off the crown part of the tooth obtained in step (1), keep the root part and store it in a container containing In a PBS culture bottle or other vessel, seal the bottle with parafilm and store in a refrigerator at 4°C;

[0065] (3) Use a dental pulp extraction needle to completely extract the pulp tissue in the root of the tooth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com